Phased array ultrasonic detection device for small-diameter pipe weld joint and working method thereof

An ultrasonic testing and phased array technology, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. To avoid the danger of high-altitude falling, to ensure the measurement accuracy, and to improve the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

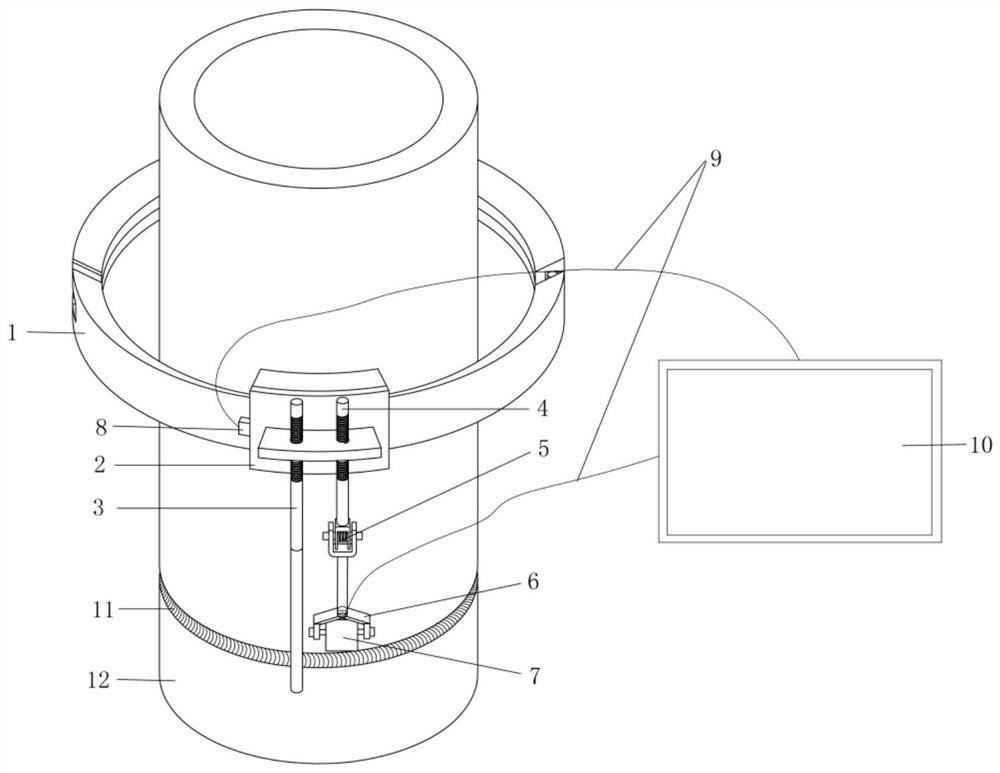

[0031] like figure 1 , the phased array ultrasonic detection device for small-diameter pipe welds of the present invention includes a fixed ring rail 1 and a moving scanning slider 2; the fixed ring rail 1 is a two-lobed structure, and the inner circumference of the fixed ring rail 1 is A chute is provided, and several compensation blocks are arranged in the chute, and the compensation blocks can be connected with the connection holes at the bottom of the chute through fasteners, and the curvature inside the compensation block matches the diameter of the small-diameter pipe 12 to be measured; The block 2 is slidably arranged on the fixed ring rail 1;

[0032]The moving scanning slider 2 is connected with a dimension measuring component 3, a probe mounting compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com