A kind of pole plate connecting method of lead-acid storage battery

A technology of lead-acid battery and connection method, which is applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., and can solve the problems of toxic gas unhealthy, low efficiency of casting welding machine, high cost, etc.

Active Publication Date: 2022-05-31

铅锂智行(北京)科技有限公司

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the prior art, the connection process of lead-acid battery plates adopts manual welding or welding by a casting welding machine. Manual welding will produce a large amount of toxic gas, which is not conducive to health and also seriously affects production efficiency. The welding method of casting welding machine is one On the one hand, there is the phenomenon of empty welding, which affects the quality of the battery; on the other hand, the use of casting welding machines is low in efficiency and high in cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

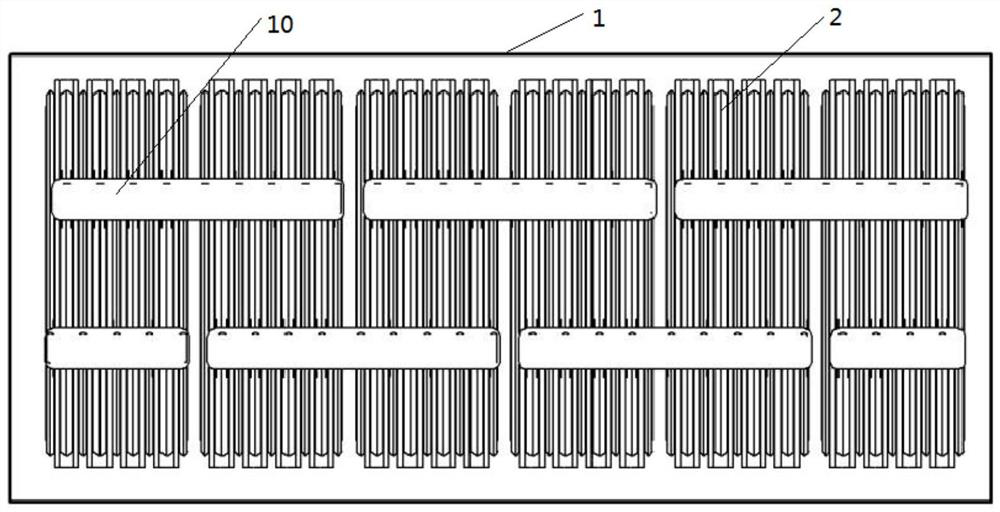

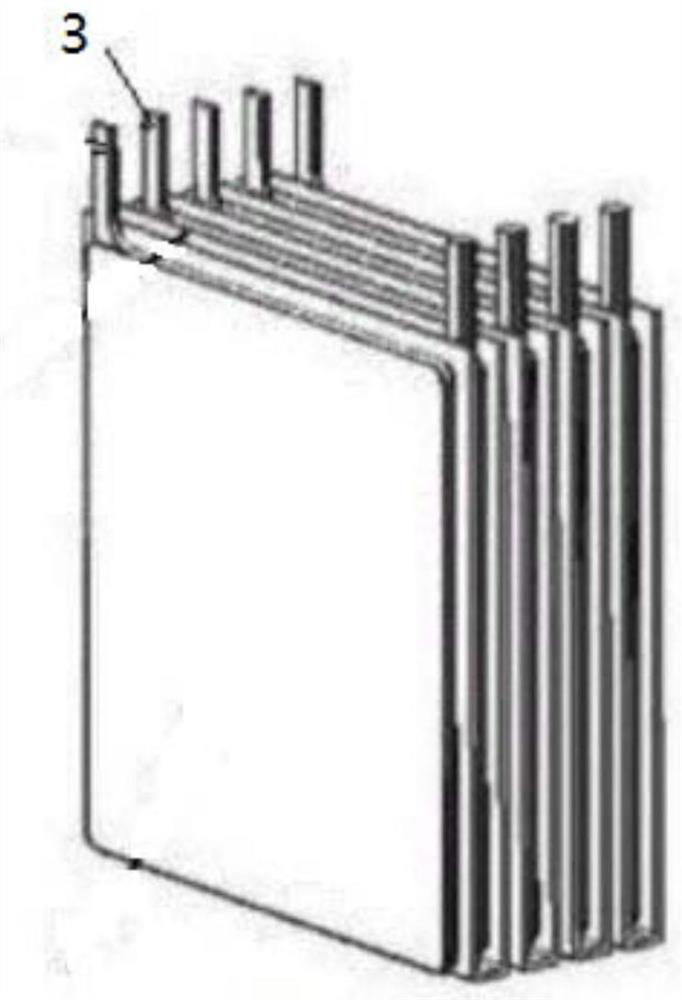

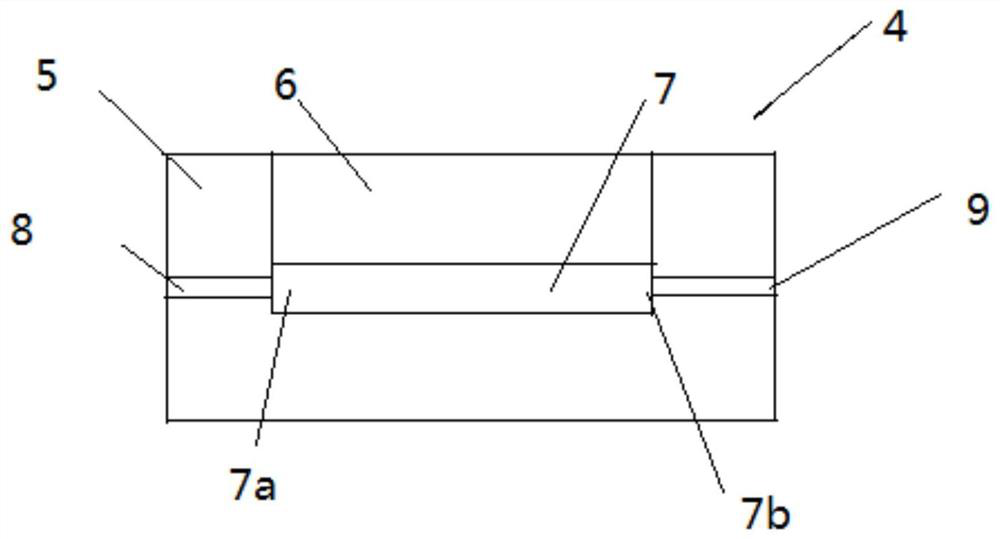

The invention relates to a method for connecting pole plates of a lead-acid storage battery. The pole lugs of a pole group are inserted into a mould; the fusible metal in the mould is hot-melted; after the fusible metal is melted into a liquid state, it is cooled and solidified And be connected with the pole ear as a whole; demoulding. The manufacturing method of the invention has high efficiency and low cost.

Description

A kind of pole plate connection method of lead-acid battery technical field [0001] The present invention relates to the field of lead-acid battery manufacturing. Background technique In the prior art, the connection technique of lead-acid battery pole plate adopts manual welding or welding by casting welding machine. method, manual welding will produce a large amount of toxic gas, which is not good for health, and also seriously affects production efficiency. On the one hand, there is an empty welding phenomenon, which affects the quality of the battery. On the other hand, the use of a casting welding machine has low efficiency and high cost. SUMMARY OF THE INVENTION In order to solve the above-mentioned technical problem, the invention provides a kind of pole plate connection method of lead-acid battery, it is characterized in that Then, the pole ears of the pole group are deep into the mold; the fusible metal in the mold is hot-melted; and the fusible metal is me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M10/14

CPCH01M10/14Y02P70/50

Inventor 丁建华

Owner 铅锂智行(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com