Box-type high-speed motor

A high-speed motor and box-type technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve high stability, reduce fault sources, and simplify the rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

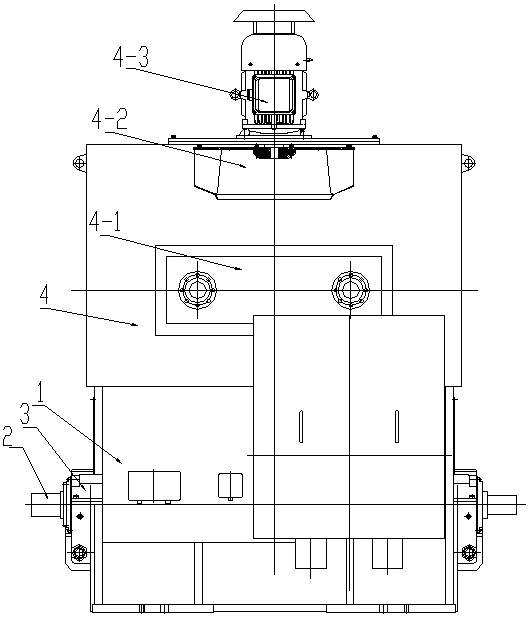

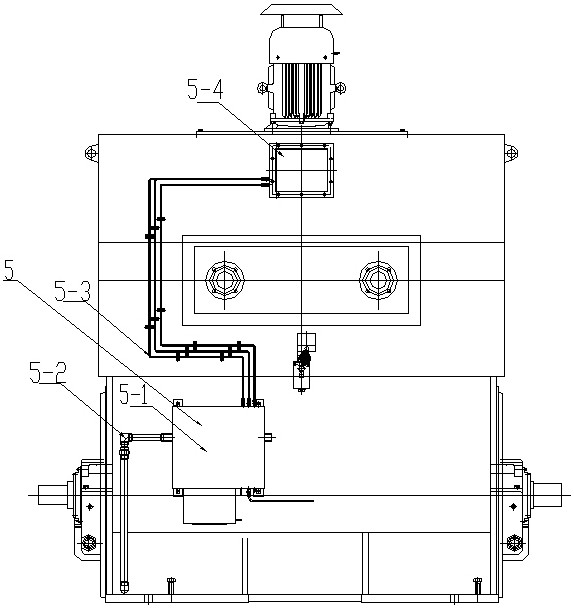

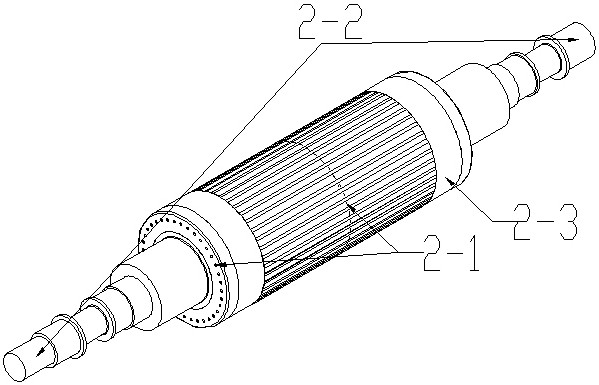

[0034] Such as Figure 1 to Figure 5 As shown, a box-type high-speed motor of the present invention is mainly composed of a box-type motor stator 1, a bearing 3 installed on the box-type motor stator frame, and a motor rotor 2 supported by the bearing. The cooler is located in the box type motor top.

[0035] In order to reduce harmonic loss, different from conventional motor rotor chute technology, the invention uses chute technology for the stator 1 core of the box-type motor, which can simplify the rotor structure.

[0036] The bearing 3 adopts a non-standard end cover type tilting pad bearing, the motor end cover 3-1 and the bearing seat 3-2 are of an integrated structure, and the motor end cover 3-1 is directly located under the bearing seat 3-2. Compared with the A-type bearings of conventional box-type motors, the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com