Raw material screening device for canned fruit processing

A technology of canned fruit and screening device, which is applied in the directions of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of time-consuming and laborious screening methods, and achieve the effects of improving the overall use effect, reducing the impact and facilitating the collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

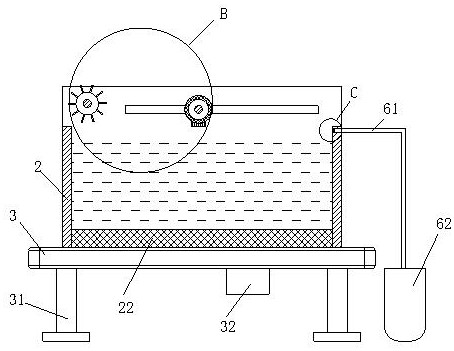

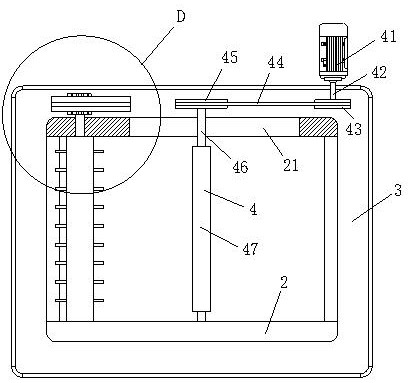

[0026] As an embodiment of the present invention, the anti-overflow assembly 6 includes an L-shaped pipe 61 and a bucket 62; the L-shaped pipe 61 runs through the side wall of the box body 2 and is located on the top of the box body 2; Bucket 62 is placed on the ground, and its top is connected with L-shaped pipe 61; One end of described L-shaped pipe 61 is provided with filter screen 611; The water level inside rises substantially, and when the water level reaches the height of the position where the L-shaped pipe 61 is located, the water will flow from the L-shaped pipe 61 into the bucket 62.

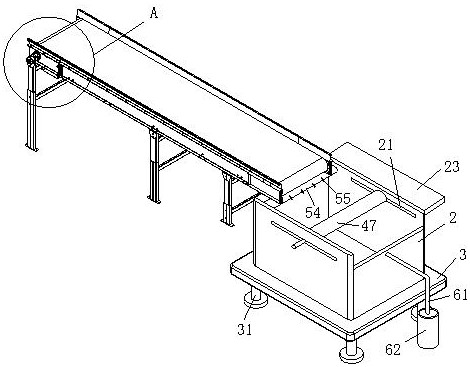

[0027] As an embodiment of the present invention, the bottom of the box 2 is provided with an elastic plate 22; the bottom of the base 3 is provided with a support column 31; the bottom of the base 3 is also provided with a drain port 32, and the drain port 32 is in communication with the box body 2; the transmission device 1 includes a second motor 11, a conveyor belt 12 and a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com