A resistance spot welding method for ultra-high-strength thermoformed steel plates

A technology of resistance spot welding and strong heating, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low transition temperature of ultra-high-strength hot-formed steel plate, long cooling cycle, high strength and carbon equivalent, etc. Achieve the effects of improving solder joint strength, reducing body-in-white vehicle weight, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

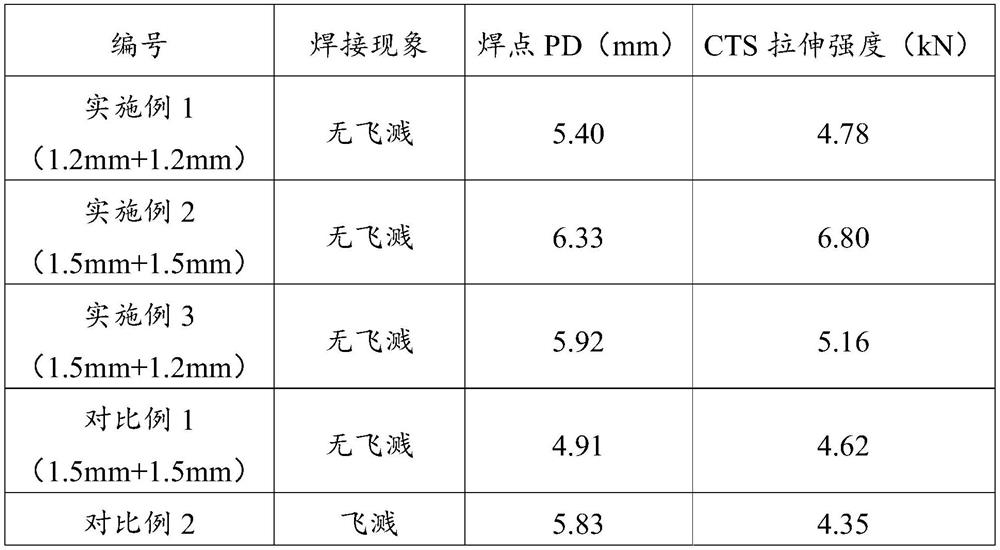

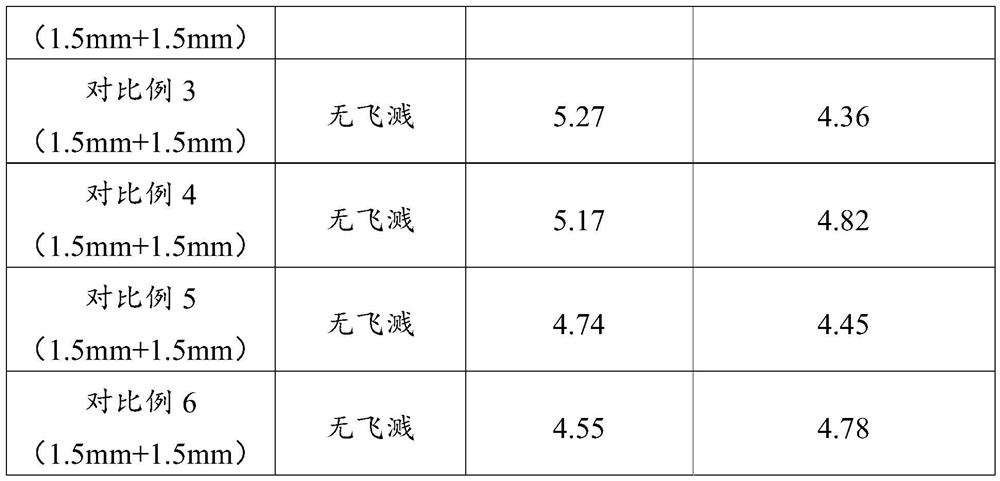

Embodiment 1

[0023] 1.8GPa hot-formed steel for testing: thickness 1.2mm, tensile strength 1853MPa, C content 0.35%, carbon equivalent 0.44%.

[0024] 1) The first process section: apply a current of 9KA to the ultra-high-strength hot-formed steel plate to be welded, and the time is 1cyc;

[0025] 2) The second process section: then apply a current of 7KA to the ultra-high-strength hot-formed steel plate after the first process section, and the time is 15cyc;

[0026] 3) The third process section: then apply a current of 7.5KA to the ultra-high-strength hot-formed steel plate after the second process section, and the time is 10cyc;

[0027] 4) The fourth process section: Next, a current of 8KA is applied to the ultra-high-strength hot-formed steel plate after the treatment in the third process section, and the time is 4cyc.

Embodiment 2

[0029] 1.8GPa hot-formed steel for testing: thickness 1.5mm, tensile strength 1813MPa, C content 0.35%, carbon equivalent 0.44%.

[0030] 1) The first process section: apply a current of 10KA to the ultra-high-strength hot-formed steel plate to be welded, and the time is 1cyc;

[0031] 2) The second process section: then apply a current of 7.5KA to the ultra-high-strength hot-formed steel plate after the first process section, and the time is 12cyc;

[0032] 3) The third process section: then apply a current of 8KA to the ultra-high-strength hot-formed steel plate after the second process section, and the time is 10cyc;

[0033] 4) The fourth process section: Next, a current of 10KA is applied to the ultra-high-strength hot-formed steel plate after the treatment in the third process section, and the time is 2cyc.

Embodiment 3

[0035] 1.8GPa hot-formed steel for the test: the thickness of the two steel plates is 1.5mm and 1.2mm, the corresponding tensile strengths are 1813MPa and 1853MPa respectively, the C content is 0.35%, and the carbon equivalent is 0.44%.

[0036] 1) The first process section: apply a current of 8.5KA to the ultra-high-strength hot-formed steel plate to be welded, and the time is 2cyc;

[0037] 2) The second process section: then apply a current of 7.5KA to the ultra-high-strength hot-formed steel plate after the first process section, and the time is 10cyc;

[0038] 3) The third process section: Then apply a current of 8.5KA to the ultra-high-strength hot-formed steel plate after the second process section, and the time is 10cyc;

[0039] 4) The fourth process section: Next, a current of 9KA is applied to the ultra-high-strength hot-formed steel plate after the treatment in the third process section, and the time is 4cyc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com