A processing method of ceramic-based waverider structure radome

A processing method and radome technology are applied in the processing field of ceramic-based waverider structure radomes, which can solve problems such as difficulty in establishing machining benchmarks for special-shaped radomes, achieve convenient and quick machining allowance, reduce errors, and improve tool setting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

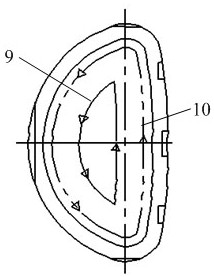

[0026] The processing method of the ceramic-based waverider structure radome disclosed in this embodiment includes:

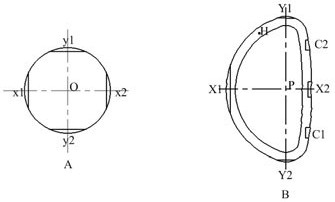

[0027] S1: Take the dial indicator and the radome blank 1, establish the first positioning reference, the second positioning reference, the length reference and the first processing reference on the radome blank 1 to construct the radome blank 1 coordinate system, And record the difference parameters of the first positioning reference and the second positioning reference measured by the dial indicator;

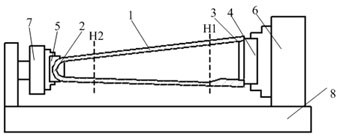

[0028] S2: Take the boring and milling machine 8 and the radome blank 1, press and clamp the radome blank 1 on the boring and milling machine 8 with the big end 3 end face vertical through the outer surface of the radome blank 1, and then according to The difference parameter of S1 adjusts the boring and milling machine 8 to align the radome blank 1;

[0029] S3: adjust the boring and milling machine 8 according to the first positioning reference, the second pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com