Osmanthus jelly cutting device

A cutting device and pastry technology, applied in metal processing, food science, etc., can solve the problems of insufficient cutter movement, excessive movement, and inability to adjust the distance between cutters, etc., and achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

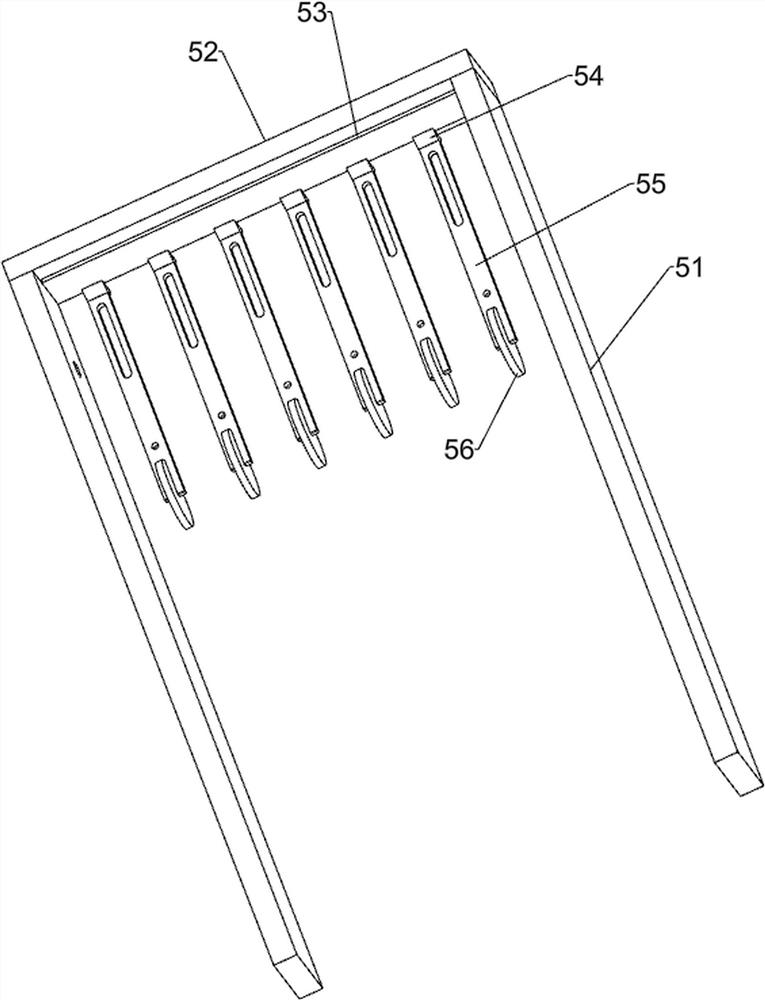

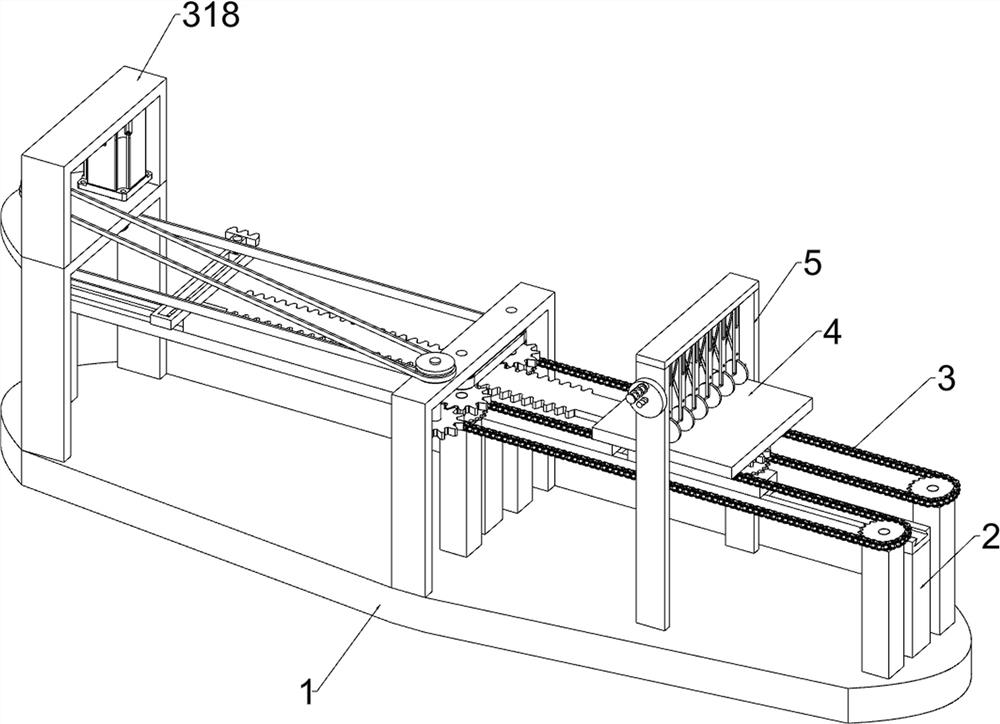

[0023] A kind of sweet-scented osmanthus pastry cutting device, such as Figure 1-3 As shown, it includes a base 1, a slide rail 2, a sliding mechanism 3, a placement plate 4 and a cutting mechanism 5, the top of the base 1 is fixedly connected with the slide rail 2, the top of the base 1 is provided with a sliding mechanism 3, and the sliding mechanism 3 is provided with a placement The board 4 is provided with a cutting mechanism 5 on the top of the base 1 .

[0024] When people need to use this device, first people will place the sweet-scented osmanthus cake that needs to be cut on the placement plate 4, since the placement plate 4 is located on the right side of the cutting mechanism 5 in the initial state, after the sweet-scented osmanthus cake is placed, people can start sliding Mechanism 3 makes the sliding mechanism 3 operate, drives the placement plate 4 and the osmanthus cake to move to the left, and when the osmanthus cake moves below the cutting mechanism 5, the cu...

Embodiment 2

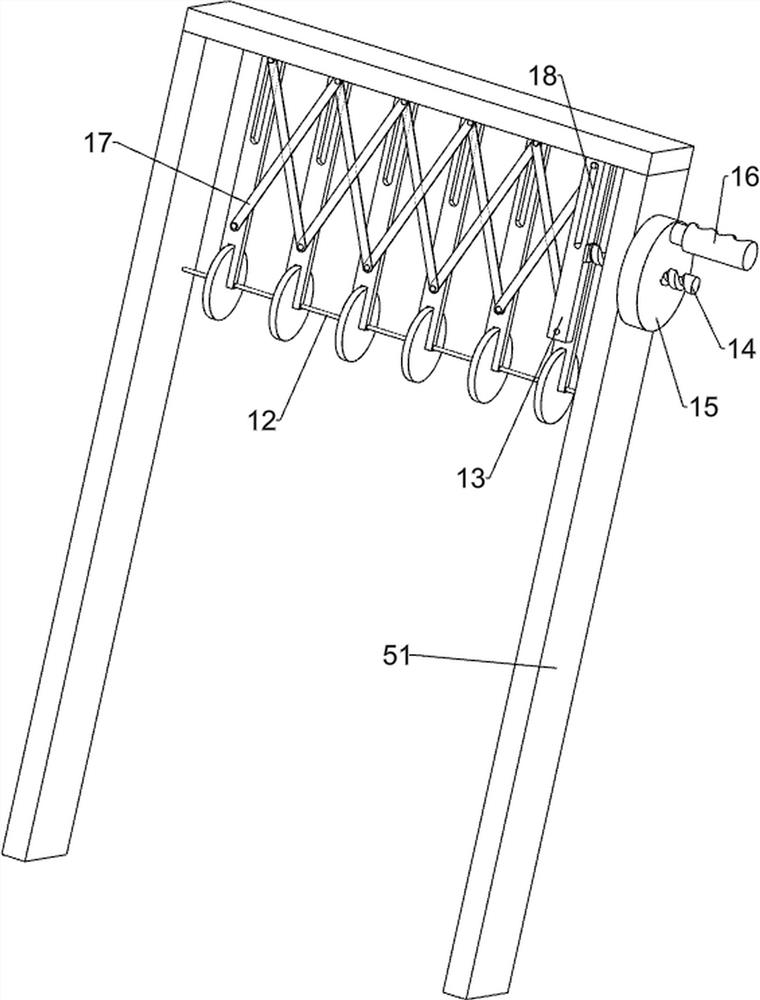

[0030] On the basis of Example 1, such as Figure 4-5 As shown, it also includes the first rotating rod 6, the second circular gear 7, the second rotating rod 8, the third circular gear 9, the belt conveyor 10, the fourth circular gear 11 and the spur rack 111, and the mounting frame in the middle The front side of the 310 is provided with a first rotating rod 6 in a rotating manner, and the lower part of the first rotating rod 6 is provided with a second circular gear 7, the second circular gear 7 meshes with the first circular gear 320 on the front side, and the mounting bracket on the left side 310 left rotating type is provided with a second rotating rod 8, the second rotating rod 8 bottom is fixedly connected with a third circular gear 9, a belt transmission device 10 is arranged between the second rotating rod 8 and the first rotating rod 6, the first Both the rotating shaft 33 and the second rotating shaft 36 are provided with fourth round gears 11, the number of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com