Asphalt auxiliary pouring equipment for municipal road cracks

A technology for municipal roads and cracks, applied in the field of asphalt auxiliary pouring equipment for municipal road cracks, can solve the problems of low filling efficiency, poor accuracy, and high asphalt temperature, and achieve the effect of ensuring temperature uniformity, improving stirring uniformity, and ensuring filling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

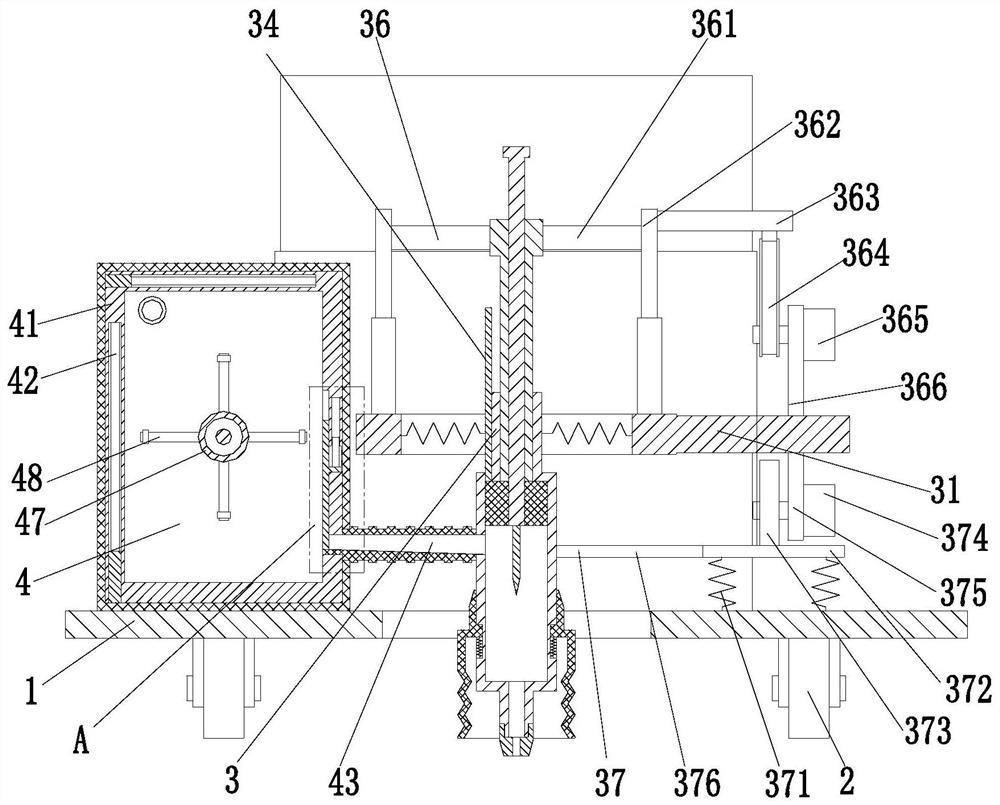

[0031] Such as Figure 1 to Figure 7 As shown, a municipal road cracked asphalt auxiliary pouring equipment includes a frame 1, a walking wheel 2, a pouring device 3 and a material storage box 4; the frame 1 is an L-shaped structure, and the vertical end of the frame 1 is up and down Telescopic structure, the lower end of the frame 1 is equipped with a walking wheel 2, the pouring device 3 and the storage box 4 are installed on the frame 1, and the middle part of the frame 1 is provided with a working tank; where:

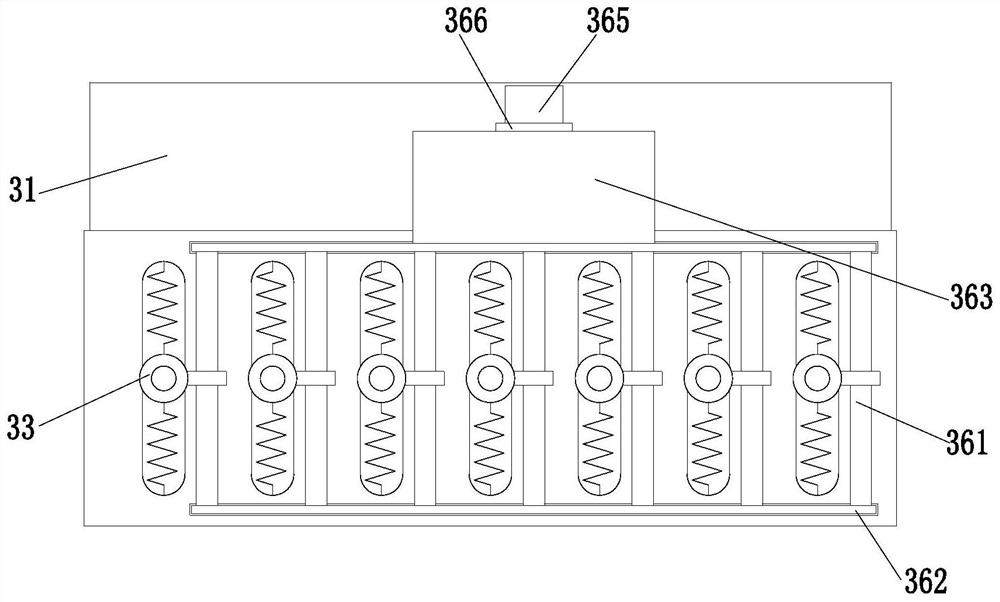

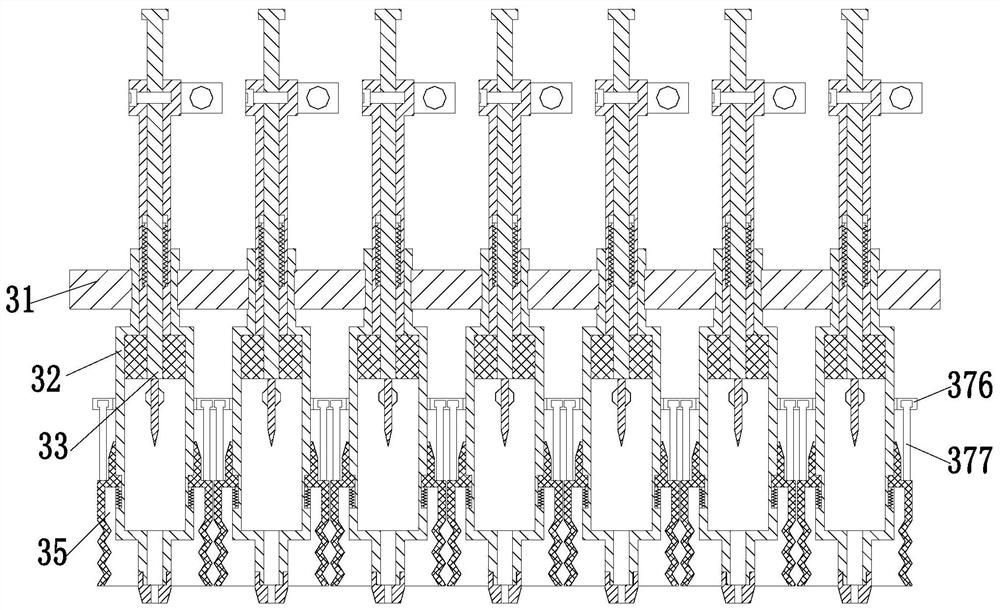

[0032] The pouring device 3 includes a fixed plate 31, a pouring cylinder 32, a piston rod 33, a baffle plate 34, an extrusion cover 35, a No. 1 driving mechanism 36 and a No. 2 driving mechanism 37. The fixed plate 31 is installed on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap