Premixed flow-state solidified soil foundation trench backfill construction method

A technology of solidifying soil and ready-mixing, which is applied in basic structure engineering, excavation, construction, etc. It can solve the problems of difficult construction, long backfilling period, and difficult to control the quality of backfilling, and achieves convenient construction process, short construction period and compactness. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

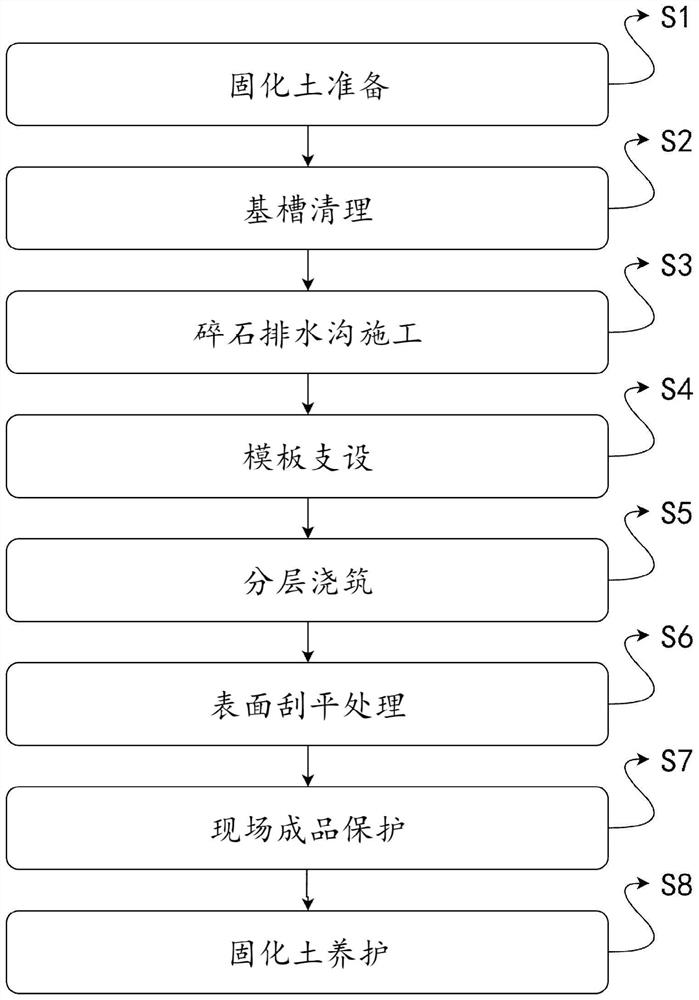

Method used

Image

Examples

Embodiment 1

[0064] The construction general contracting project of the CIC Land Beicheng Times (Phase II) project (Plot A) has a planned construction net land area of 64882.22m2 and a planned total construction area of 295131.07m2, of which the above-ground construction area is 213196.05m2 and the underground construction area is 81935.02m2. The architectural design of the construction site is ±0.00=409.50m, the leveling elevation of the site is considered as 406.0m~411.00m, and the excavation depth of the foundation pit is about 7.0m~13.0m;

[0065] (1) To prepare the solidified soil, communicate with the solidified soil unit in advance, through on-site survey, select the on-site construction station to supply the solidified soil for the construction, take the original soil from the site for the test mix of the solidified soil, and after the trial mix of the solidified soil, determine the solidified soil The mix ratio of the soil is curing agent: water: soil = 1:1.15:5.36. Considering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com