Light-duty robot for automatically coating surface of cable with insulating material

An insulating material and automatic coating technology, which is applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems that the line cannot be powered off for a long time, the safety protection problem of bare wires is difficult to effectively solve, and it is difficult to coat the insulation layer. The construction process is convenient and quick, the power outage time is shortened, and the structure is compact and compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further elaborate the content of the present invention below in conjunction with accompanying drawing.

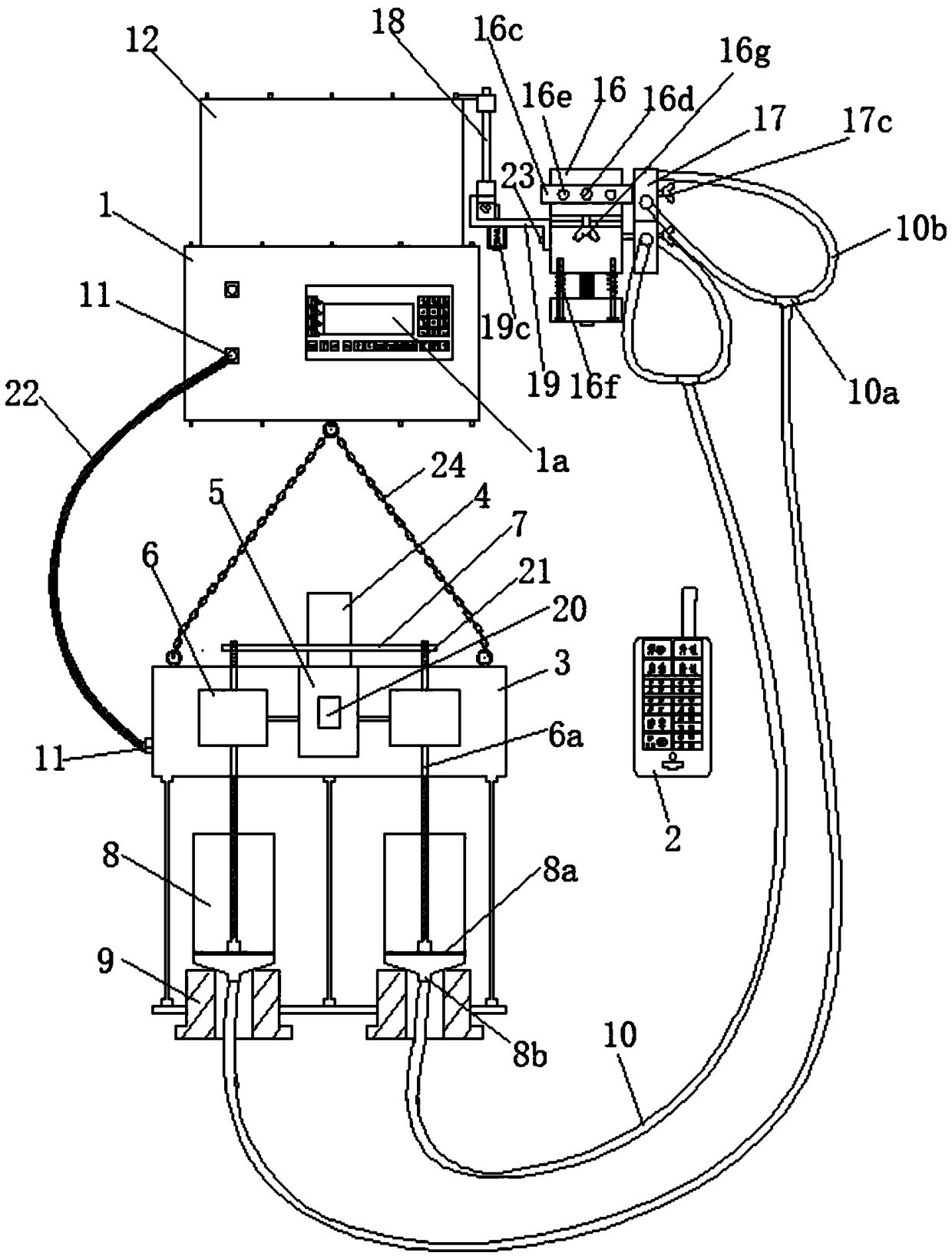

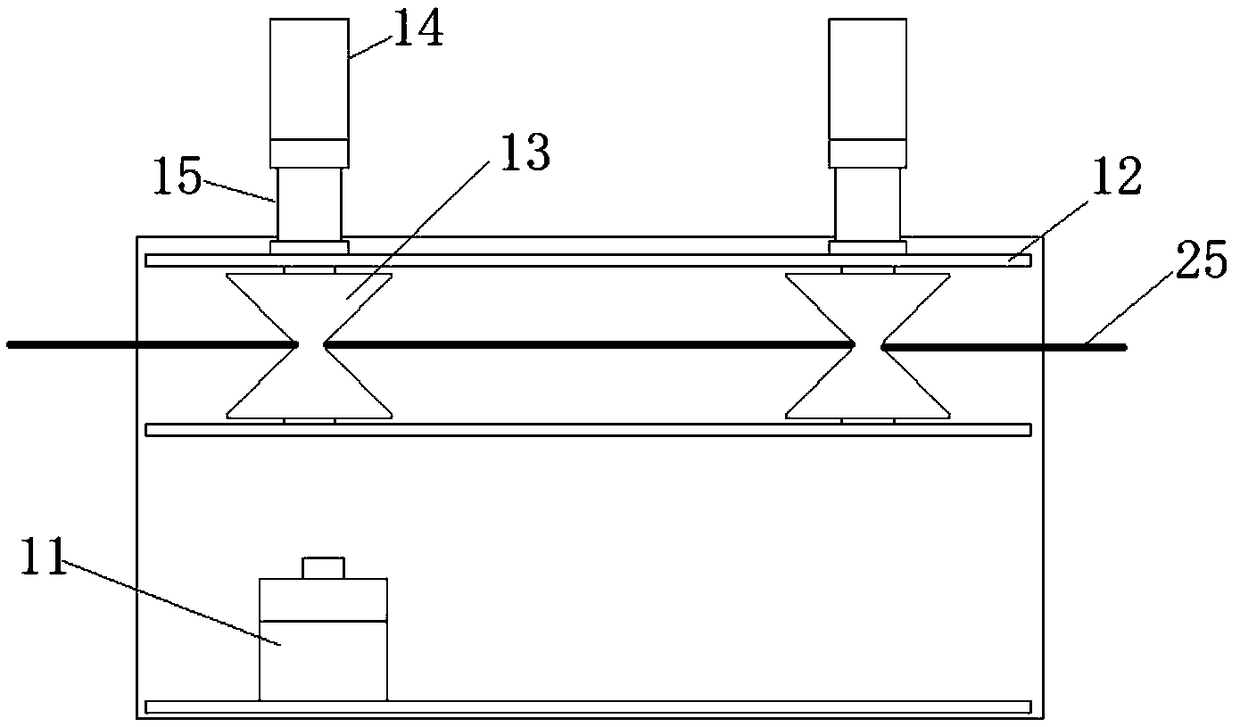

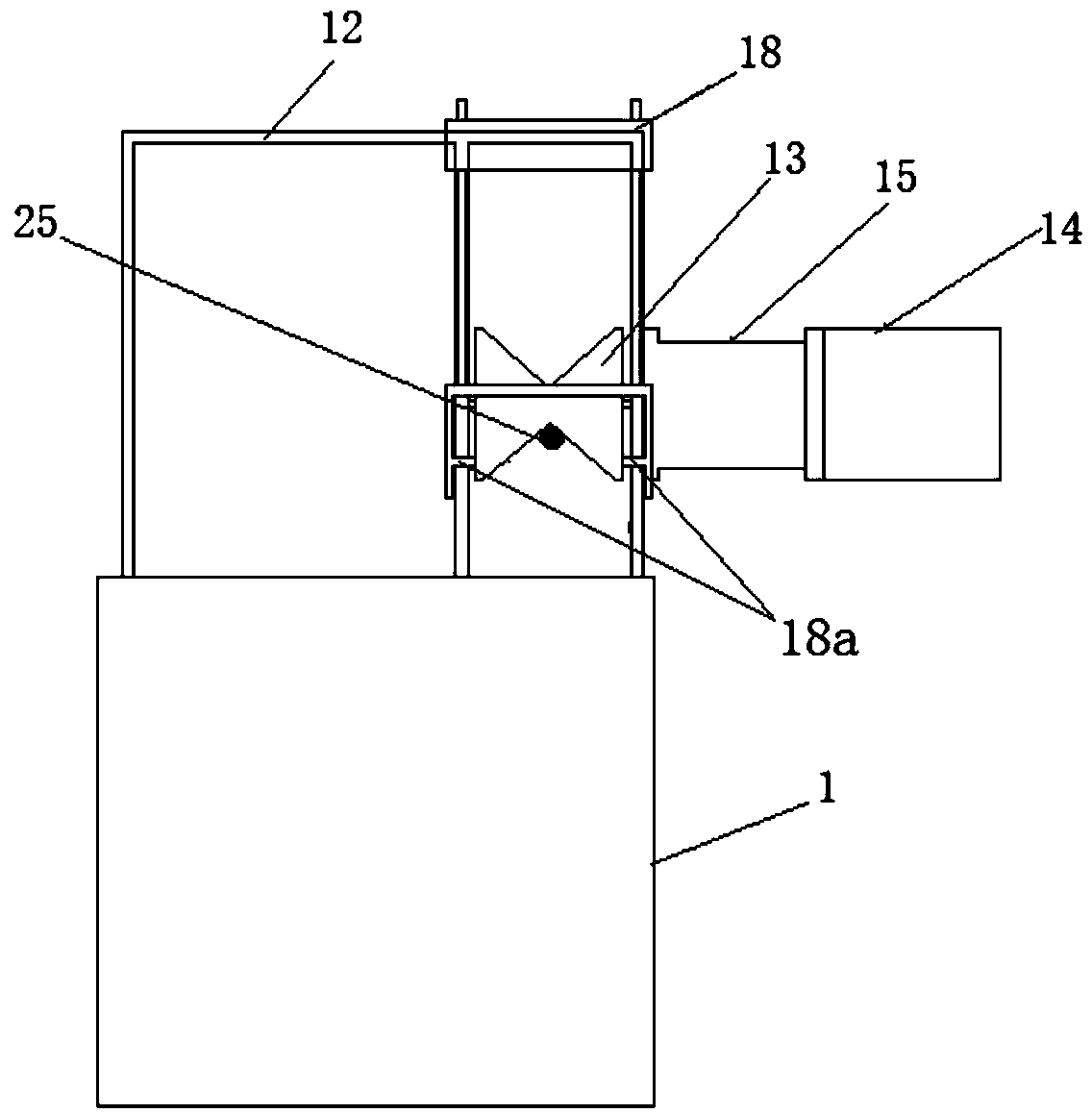

[0028] Such as figure 1 The shown portable robot that automatically coats insulating materials on the surface of cables includes a control box 1, a rubber extruding device installed under the control box, and a walking coating device that walks along the cable.

[0029] The control box 1 of the present invention is equipped with the NC three-axis controller that is remotely controlled by the remote controller 2 outside the box; The NC three-axis controller used in this embodiment is a commercially available TC5510 motion controller, and its control system adopts a high-performance 32-bit CPU. The controlled driving device can adopt stepper motor or AC servo motor, and is equipped with liquid crystal display 1a, fully enclosed touch-type operation keyboard.

[0030] The rubber extruding device of the present invention includes a mounting frame 3, a rubber extruding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com