Pure electric vehicle power assembly

A pure electric vehicle and powertrain technology, applied in transmission, transmission parts, transmission control, etc., can solve problems such as reducing the user experience, reducing the synchronization of shifting, and failing to change the alternation of shift wheels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

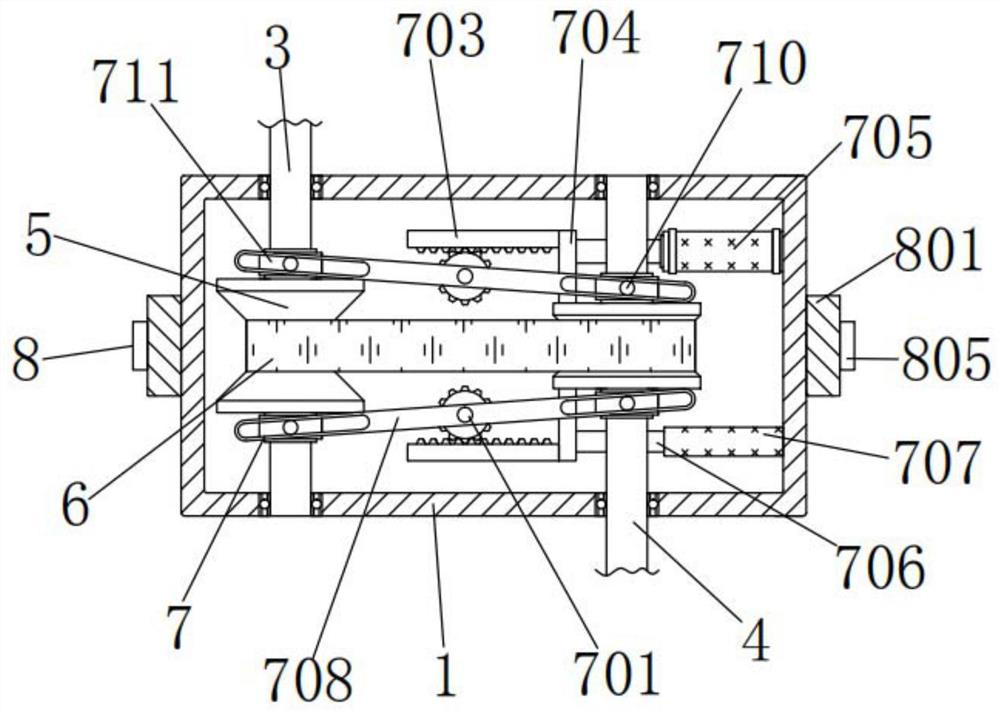

[0030] A pure electric vehicle power assembly, including a transmission lower case 1 and a transmission upper case 2, the top of the transmission lower case 1 is fastened with a transmission upper case 2, the transmission lower case 1 and the transmission upper case 2 The contact surfaces coincide, the left side of the transmission lower case 1 is rotatably connected with the driving shaft 3 through the bearing, the right side of the driving shaft 3 is provided with the driven shaft 4, and the outer wall of the driven shaft 4 is connected with the right side of the transmission lower case 1 through the bearing. Side rotation connection, the outer walls of the driving shaft 3 and the driven shaft 4 are fitted with a speed change wheel set 5 with a gap, and the speed change wheel sets 5 on both sides are connected by crawler belts 6, and the transmission assembly 7 is arranged inside the transmission lower housing 1 .

Embodiment 2

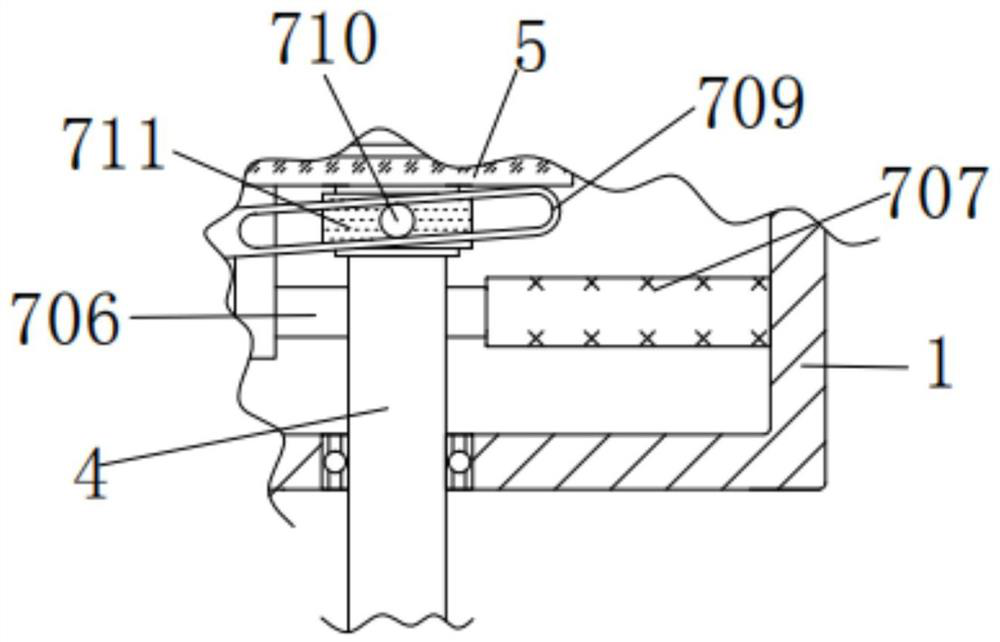

[0032] As an option, see figure 1 , 3 , 4 and 5, pure electric vehicle powertrain, the transmission assembly 7 includes a rotating rod 701, a gear 702, a rack 703, a vertical plate 704, an electric push rod 705, a cross bar 706, a horizontal cylinder 707, an oblique rod 708, and a slot 709, sliding rod 710 and shaft sleeve 711, the rear end of the rotating rod 701 is connected to the inner wall of the transmission lower housing 1 in rotation, the rotating rod 701 is located on the center line of the distance between the driving shaft 3 and the driven shaft 4, and the two rotating rods 701 About the symmetrical distribution of speed change wheel set 5, design like this makes inclined bar 708 rotate and can drive both sides change speed wheel set 5 to move simultaneously, and the outer wall of rotating bar 701 is fixedly connected with gear 702, and the outer end of gear 702 is provided with rack 704, and The inner end of the bar 704 is meshed with the outer end of the gear 702...

Embodiment 3

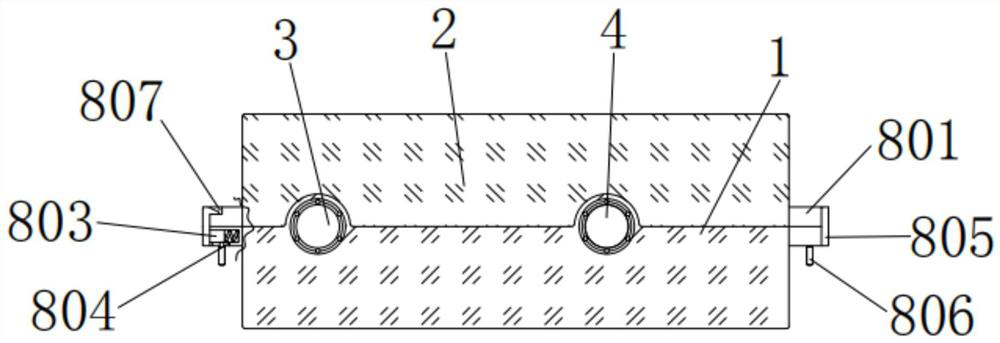

[0035] As an option, see figure 1 , 2 and 5, pure electric vehicle powertrain, the outer ends of the transmission lower case 1 and the transmission upper case 2 are provided with a clamping assembly 8, and the clamping assembly 8 includes a square protrusion 801, a circular groove 802, a circular support Rod 803, tension spring 804, limit clamping plate 805, strip shift lever 806 and limit card slot 807, the inner end of the square projection 801 on the same side is connected with the transmission lower case 1 and the transmission upper case 2 respectively. The left and right ends are fixedly connected, the inner ends of the square bumps 801 are fitted together, the left end of the square bump 801 below is processed with a circular groove 802, and the inner wall gap of the circular groove 802 is matched with a circular support rod 803. The inner end of the outer wall of the shaped pole 803 is fixedly connected with a tension spring 804, and the tension spring 804 gives the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com