Valve sheet type check valve of liquid ring vacuum pump and liquid ring compressor

A technology of liquid ring vacuum pump and liquid ring compressor, which is applied in the direction of liquid fuel engines, pumps, sliding valves, etc., can solve the problems of short service life, poor sealing, fatigue failure, etc., and achieve noise reduction, sensitive opening and closing, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

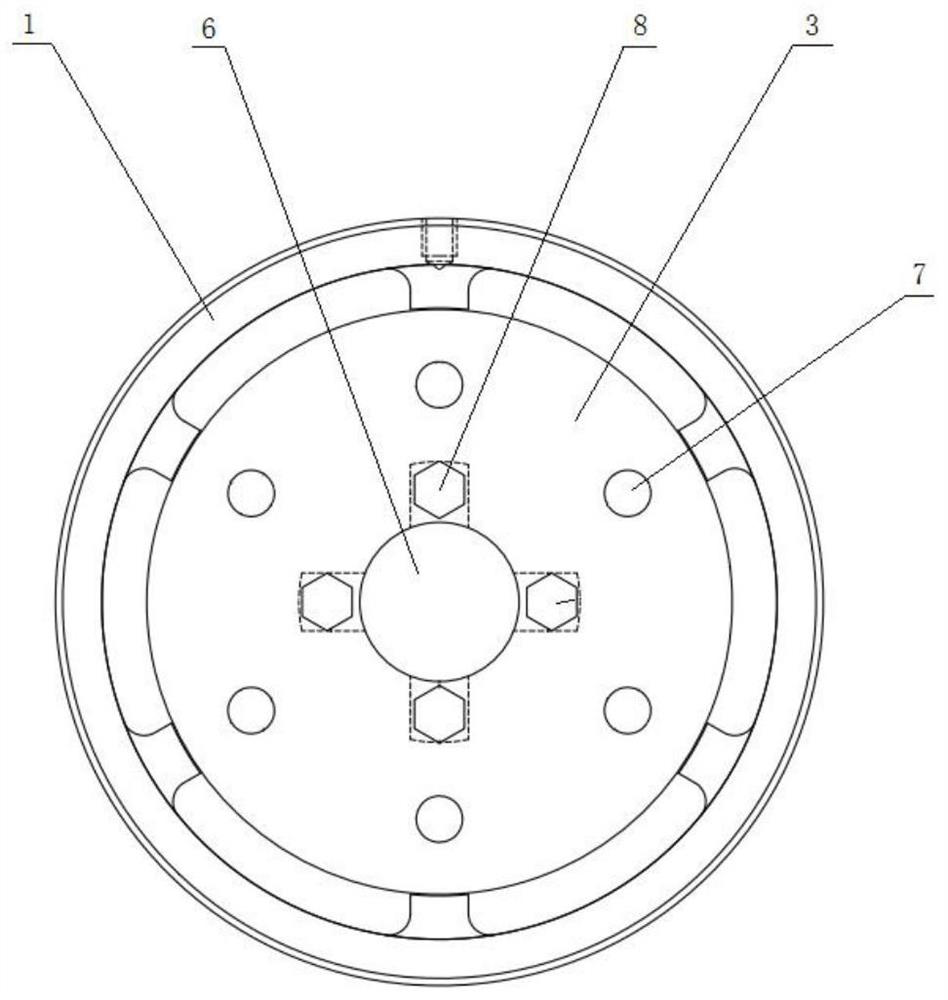

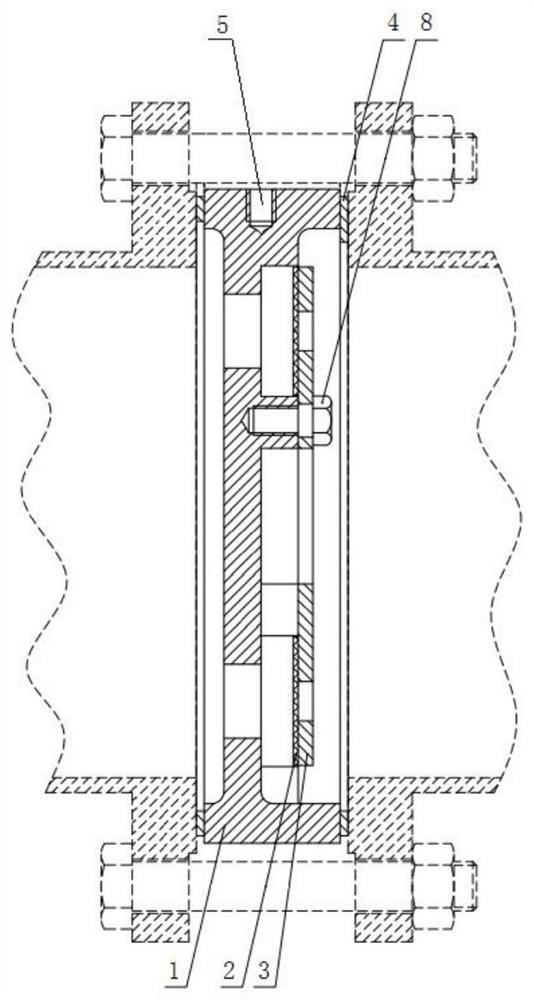

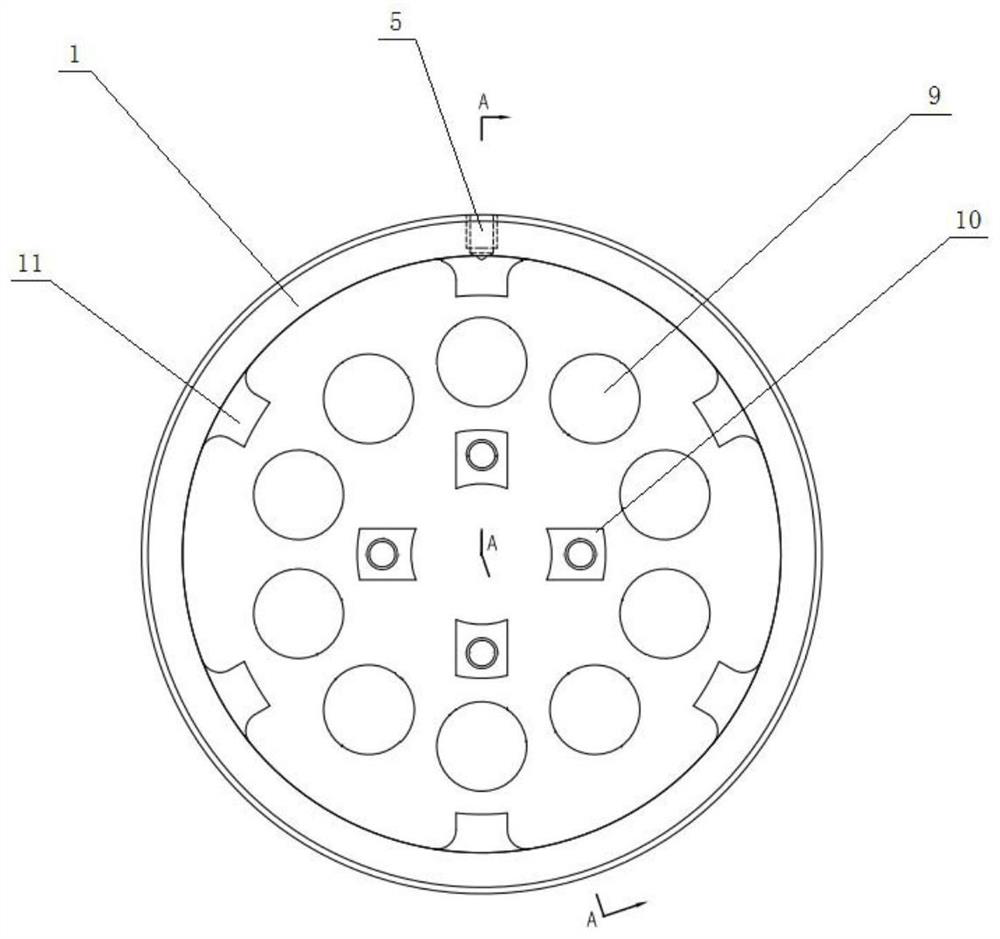

[0025] Such as Figure 1 to Figure 4 Shown: a liquid ring vacuum pump and a liquid ring compressor valve plate check valve, including a valve body 1, an annular valve plate 2 and a valve plate 3, the valve body 1 includes an annular shell and a circular ring coaxially arranged inside the shell Shaped bottom plate, the outer ring of the bottom plate and the inner wall of the shell are in a sealed connection, two concentric circles with one small and one large on the inner surface of the bottom plate are respectively provided with several axial columns 11 and several axial ventilation holes 10 , the annular angle between the inner wall of the shell and the inner side wall of the bottom plate is also provided with a number of supporting platforms 12, the annular valve plate 2 is arranged between the supporting platform 12 and the column 11, the outer edge of the valve plate 3 and the There is a gap between the inner walls of the shell. When the annular valve plate 2 is attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com