Waste heat recovery equipment and waste heat recovery method for thermal power plant

A technology for waste heat recovery equipment and thermal power plants, applied in the field of waste heat recovery, can solve problems affecting heat exchange efficiency, adjustment of stirring speed, insufficient waste heat recovery, etc., and achieve the effect of increasing heat exchange efficiency and changing stirring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

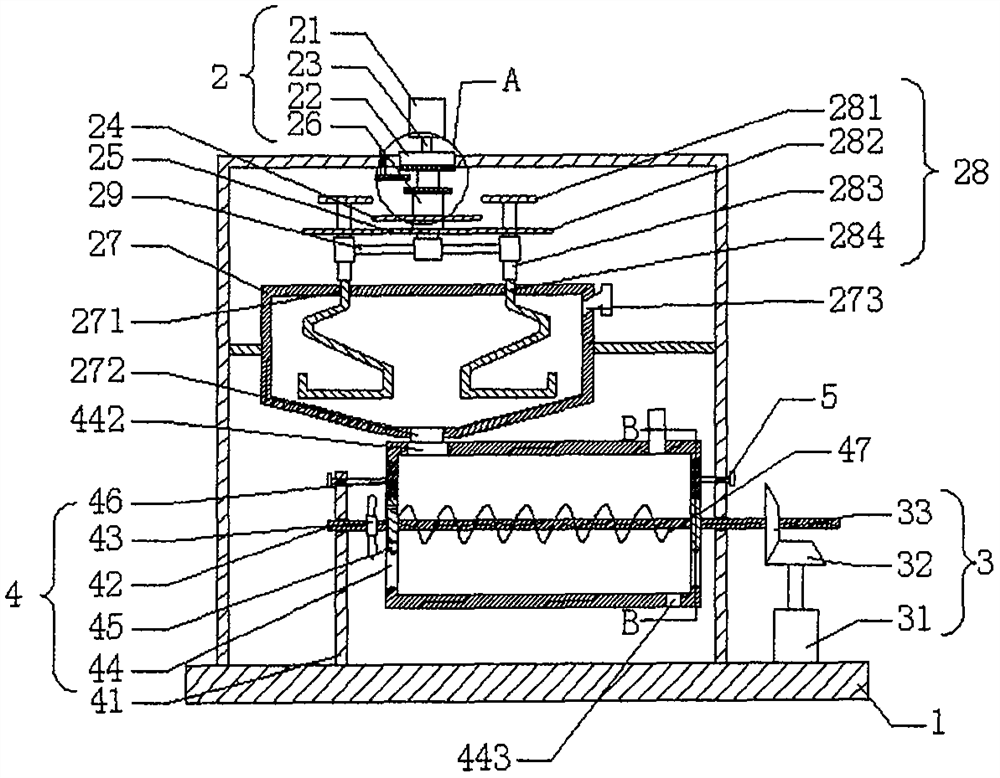

[0030] see Figure 1-4 , the waste heat recovery equipment for thermal power plants provided by the embodiment of the present invention includes a bottom plate 1, a stirring mechanism 2, a driving mechanism 3, a recovery mechanism 4 and a clamping mechanism 5, and the recovery mechanism 4 is rotatably arranged on the Above the bottom plate 1 , the driving mechanism 3 is fixedly arranged on the upper end of the bottom plate 1 , the clamping mechanism 5 is fixedly arranged on both sides of the recovery mechanism 4 , and the stirring mechanism 2 is rotatably arranged on the recovery mechanism 4 above;

[0031]The stirring mechanism 2 includes a drive motor 21, a fixed block 22, a center rod 23, a first gear 24, a second gear 25, a sliding sleeve 26, a collection funnel 27 and a stirring assembly 28. The two ends of the fixed block 22 pass through. The bracket is fixedly installed on the bottom plate 1, the driving motor 21 is fixedly arranged on the upper end of the fixing block...

Embodiment 2

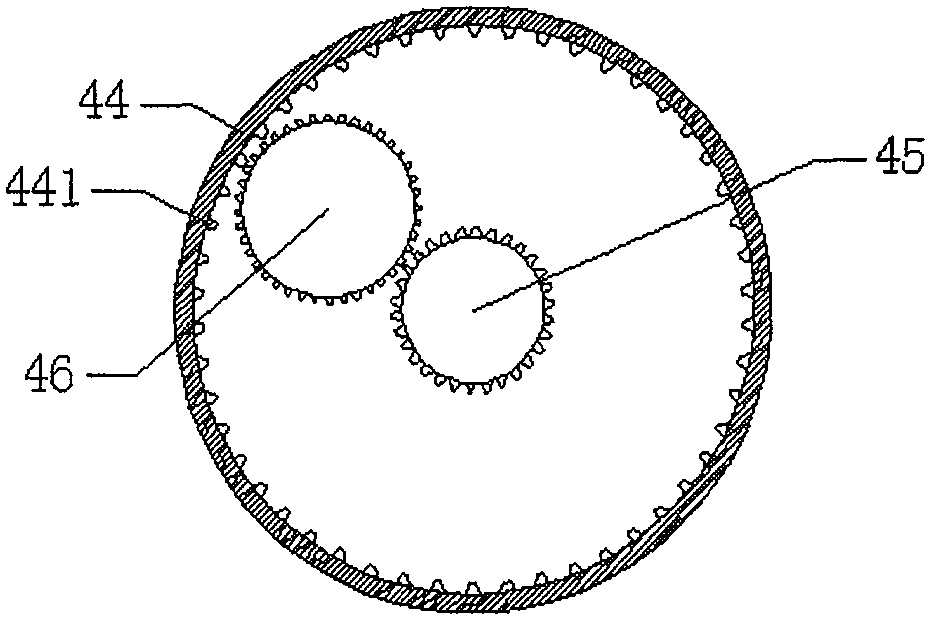

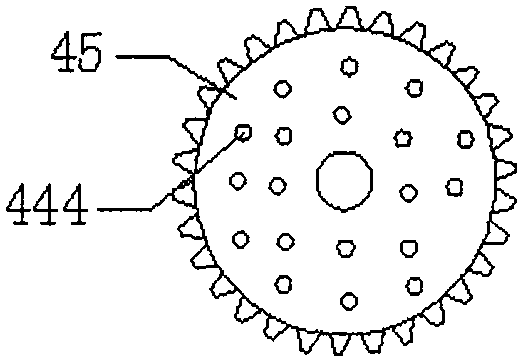

[0036] In the first embodiment, there is still a problem that the waste heat of the slag cannot be recovered and utilized. Therefore, on the basis of the first embodiment, this embodiment further includes: the recovery mechanism 4 includes two support rods 41, a rotating rod 42, a refrigeration The fan 43 , the rotating casing 44 , the fifth gear 45 , the sixth gear 46 and the auger 47 , the bottom ends of the two supporting rods 41 are fixedly installed on the upper end of the base plate 1 , and the rotating rod 42 is rotatable. The two supporting rods 41 are arranged on the two supporting rods 41, the rotating rod 42 passes through the two supporting rods 41, the rotating casing 44 is fixedly arranged on the rotating rod 42, and the rotating casing 44 is arranged horizontally. Both ends of the rotating housing 44 in the horizontal direction are provided with movable cavities, the two fifth gears 45 are fixedly arranged on the rotating rod 42 , and the two fifth gears 45 are l...

Embodiment 3

[0041] see figure 1 , in this embodiment, the present invention also proposes a waste heat recovery method for the waste heat recovery equipment of a thermal power plant, comprising the following steps:

[0042] Step 1, put the slag used by the thermal power plant into the collecting funnel 27 from the feeding port 273, start the driving motor 21, the driving motor 21 will drive the center rod 23 to rotate, and the center rod 23 will drive the second rod during the rotation process. The rotation of the gear 25 drives the fourth gear 282 to rotate, and drives the third connecting rod 283 to rotate, thereby driving the stirring rod 284 to rotate, thereby mixing and stirring the slag;

[0043] Step 2, when the stirring speed needs to be adjusted, the second connecting rod 210 is rotated, so that the third magnet 222 will leave the original position. Due to the action of the magnetic force, the first magnet 261 and the second magnet 221 will The sliding sleeve 26 drives the upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com