Transformer substation robot inspection system and inspection method thereof

A patrol inspection system and robot technology, applied in transmission systems, electrical components, inspection time patrols, etc., can solve the problems of long inspection time, low efficiency, and inability to fully utilize robot inspections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with accompanying drawing:

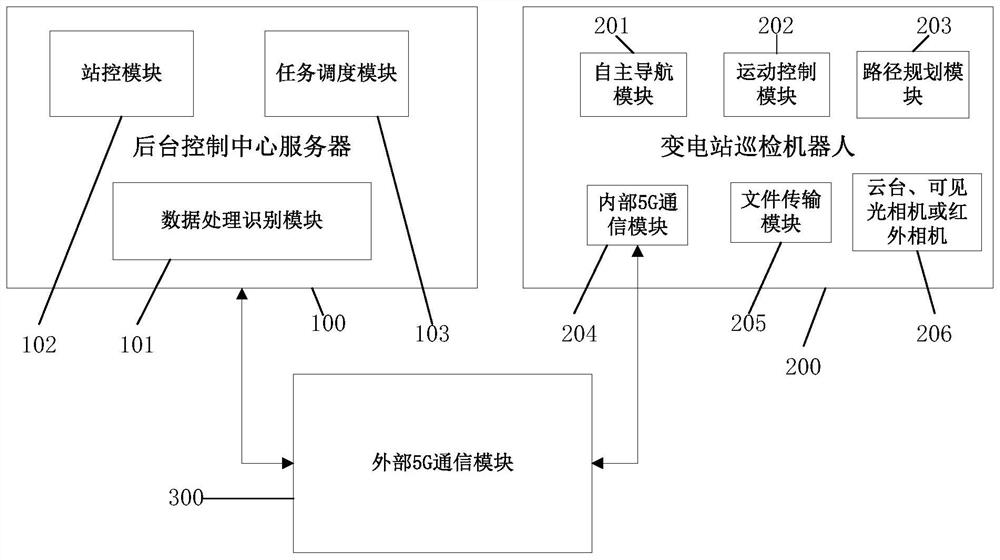

[0061] like figure 1 A substation robot inspection system shown includes an inspection robot 200 , a background control center server 100 and an external 5G communication module 300 .

[0062] The inspection robot 200 includes, but is not limited to, an autonomous navigation module 201, a motion control module 202, a path planning module 203, an internal 5G communication module 204, a file transfer module 205, a pan-tilt, and a visible light camera or an infrared camera 206 mounted on the pan-tilt. . The autonomous navigation module 201 is a slam navigation module, responsible for autonomous navigation; the motion control module 202, responsible for the underlying motion control of the robot; the path planning module 203, responsible for path planning according to the inspected equipment; the internal 5G communication module, responsible for physical layer communication; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com