Tongue rail

A track, tongue-shaped technology, applied in the direction of tracks, roads, steel rails, etc., can solve the problems of rail transit safety hazards and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

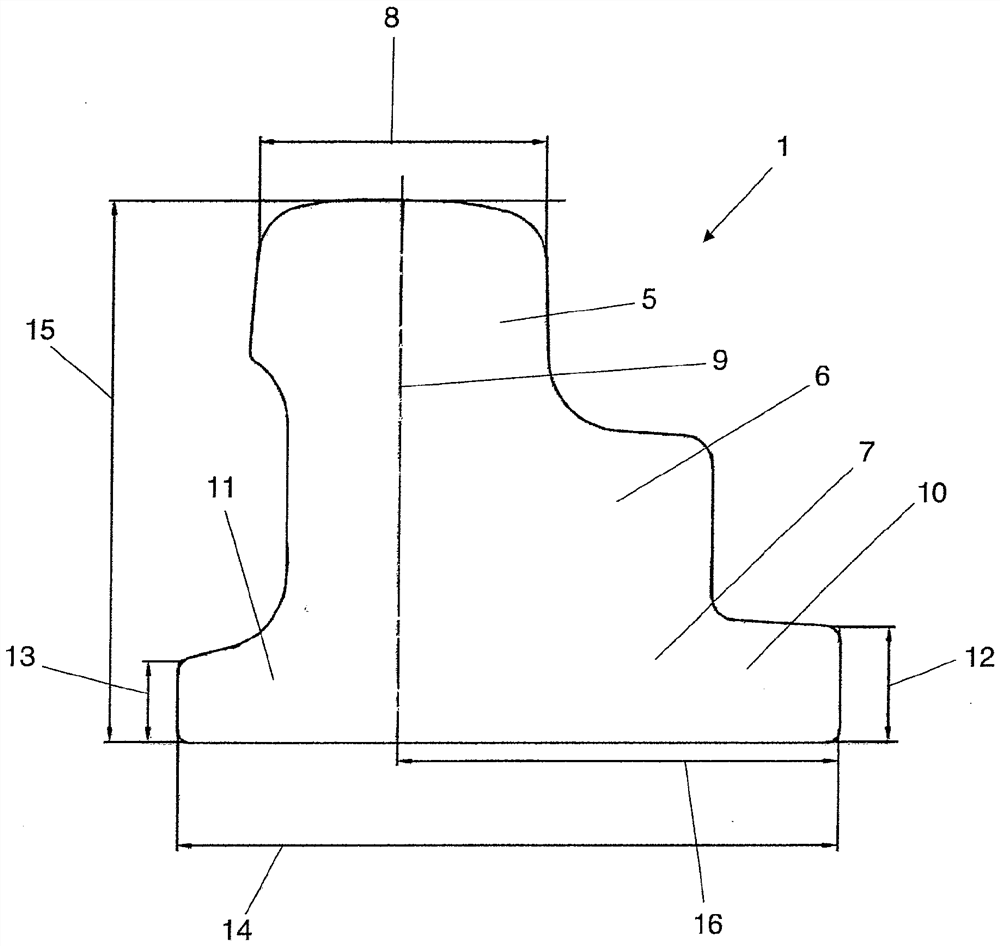

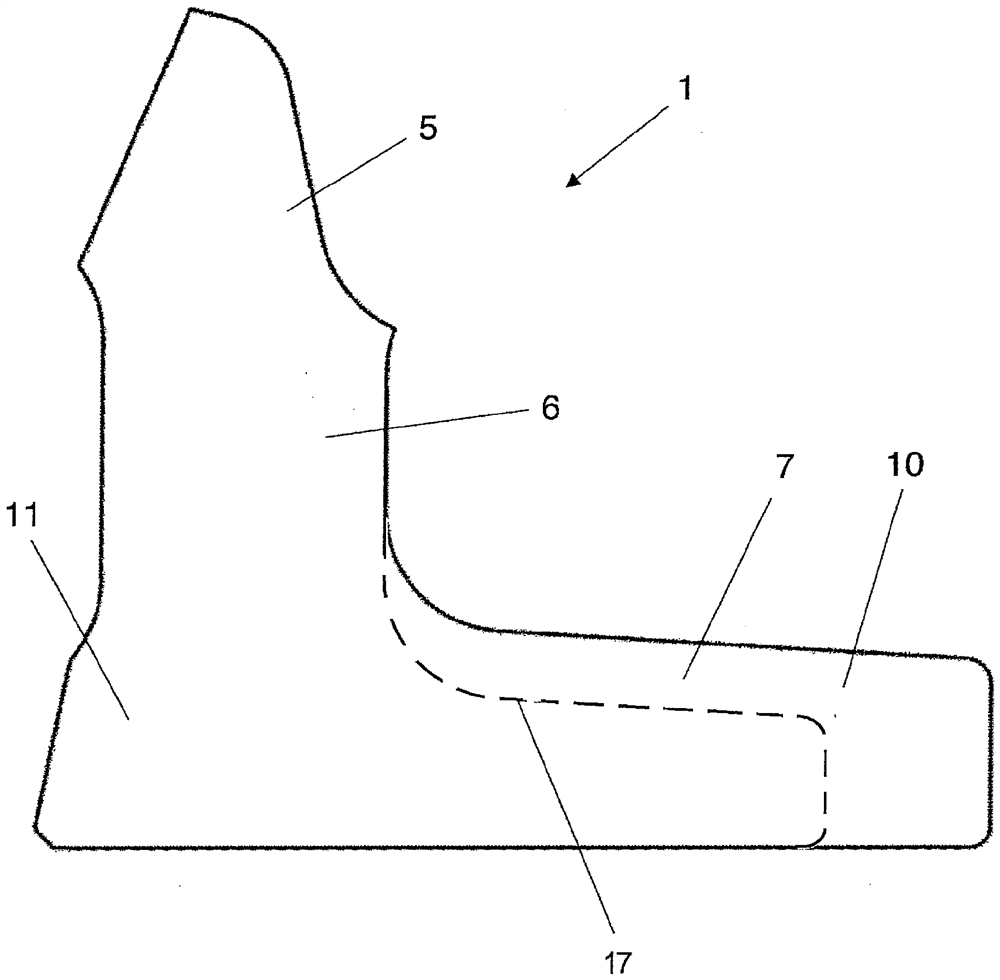

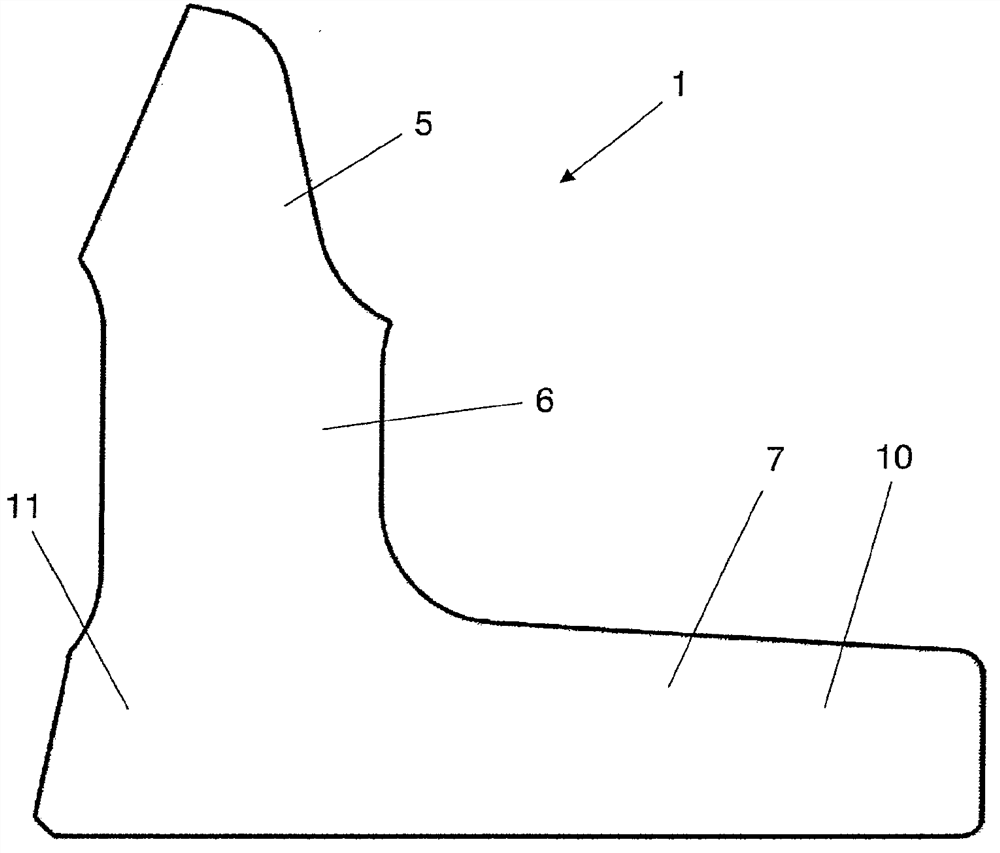

[0035] figure 1 A rail switch according to the invention is shown, comprising two tongue rails 1 and two basic guide rails 2 . The tongue rails 1 are each assigned to a base rail 2 . Three adjustment planes 3a, 3b and 3c are arranged along the switch, in which adjustment devices (not shown) and final position checking devices (not shown) are arranged for selectively guiding the tongue rail 1 towards the substantially The rail 2 is shifted to or away from the basic rail 2. In the resting state, the tongue rail 1 rests on the base rail 2 in a first longitudinal section extending from the first adjustment plane 3 a to the third adjustment plane 3 c. Furthermore, 4 designates the clamping region of the tongue rail 1 , which is located in the second longitudinal section of the tongue rail, which extends from the third adjustment plane 3 c to the clamping region 4 . The tongue rail 1 has a cross section that varies along the longitudinal extent of the tongue rail, wherein in part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com