Steel plate machining and polishing device having protection function

A polishing device and protection function technology, which is applied in the field of steel plate processing and polishing devices, can solve problems such as unfavorable processing, rough surface of the polishing wheel, poor flatness of the steel plate surface, etc., and achieve good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

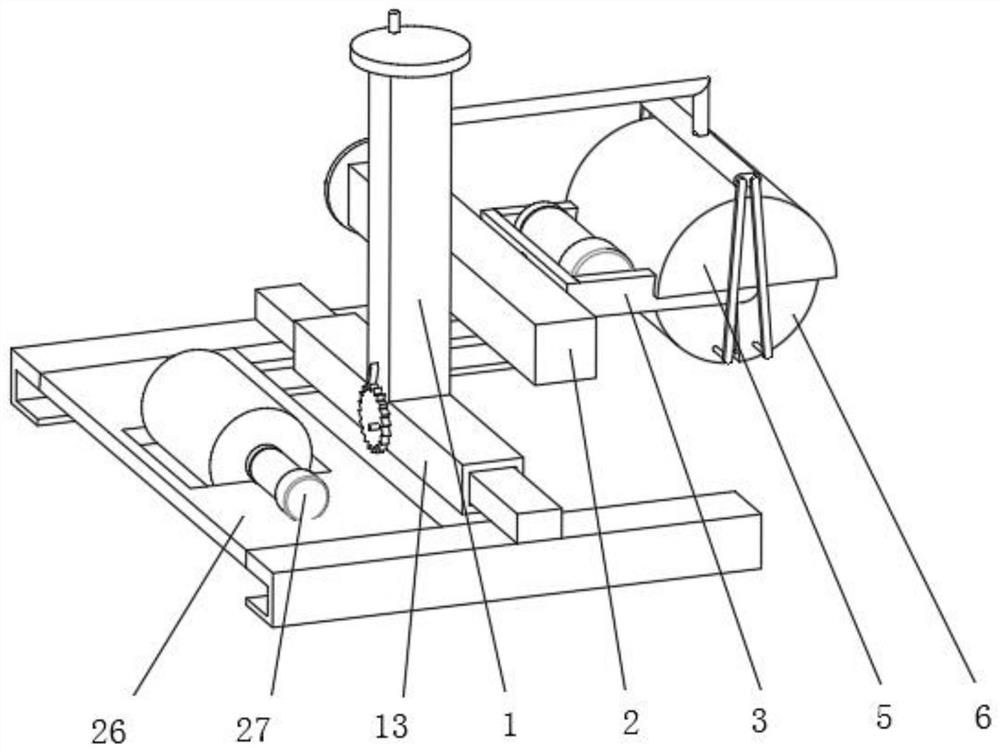

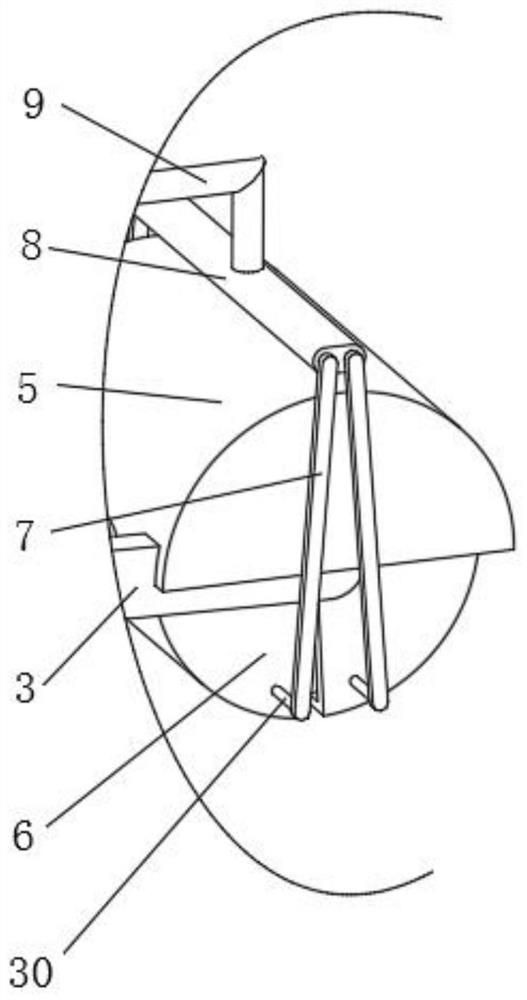

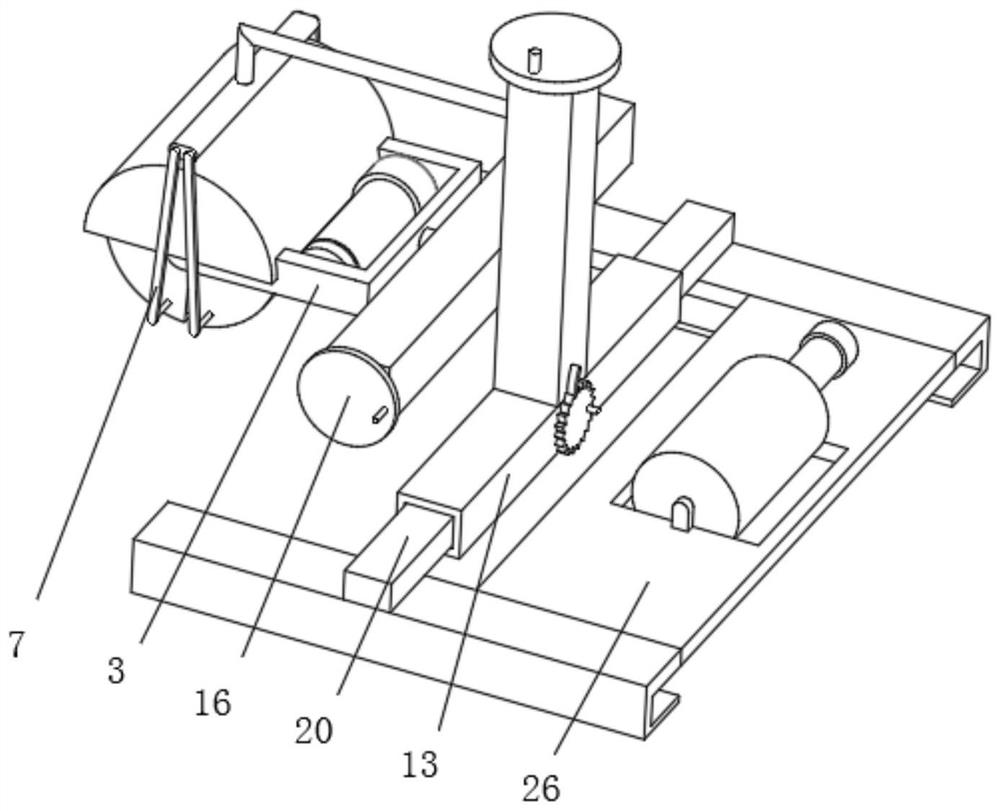

[0042] Example: Reference Figure 1-9 A steel plate processing and polishing device with a protective function is shown, including a main support cylinder 1, an adjustment mechanism is arranged inside the main support cylinder 1, and a horizontal cylinder 2 is fixedly installed on one side of the main support cylinder 1 through the adjustment mechanism, and the horizontal cylinder 2 A displacement mechanism is arranged inside, and a U-shaped frame 3 is fixedly installed on one side of the horizontal cylinder 2 through a displacement mechanism. There is the same rotating shaft, and the polishing grinding wheel 4 is fixedly sleeved on the rotating shaft. Two movable shields 6 are installed on the inner walls of the two sides of the U-shaped frame 3 close to each other. Both sides of the main shield 5 are provided with follow-up mechanisms. .

[0043] A polishing motor 10 is fixedly installed on one side inner wall of the U-shaped frame 3, a transmission chamber is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com