Variable-diameter coating stirring and mixing device for building

A stirring and mixing technology for construction, which is applied to mixers with rotating stirring devices, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problems of uneven paint mixing, uneven color, single function, etc., to achieve Easy to mix, evenly mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

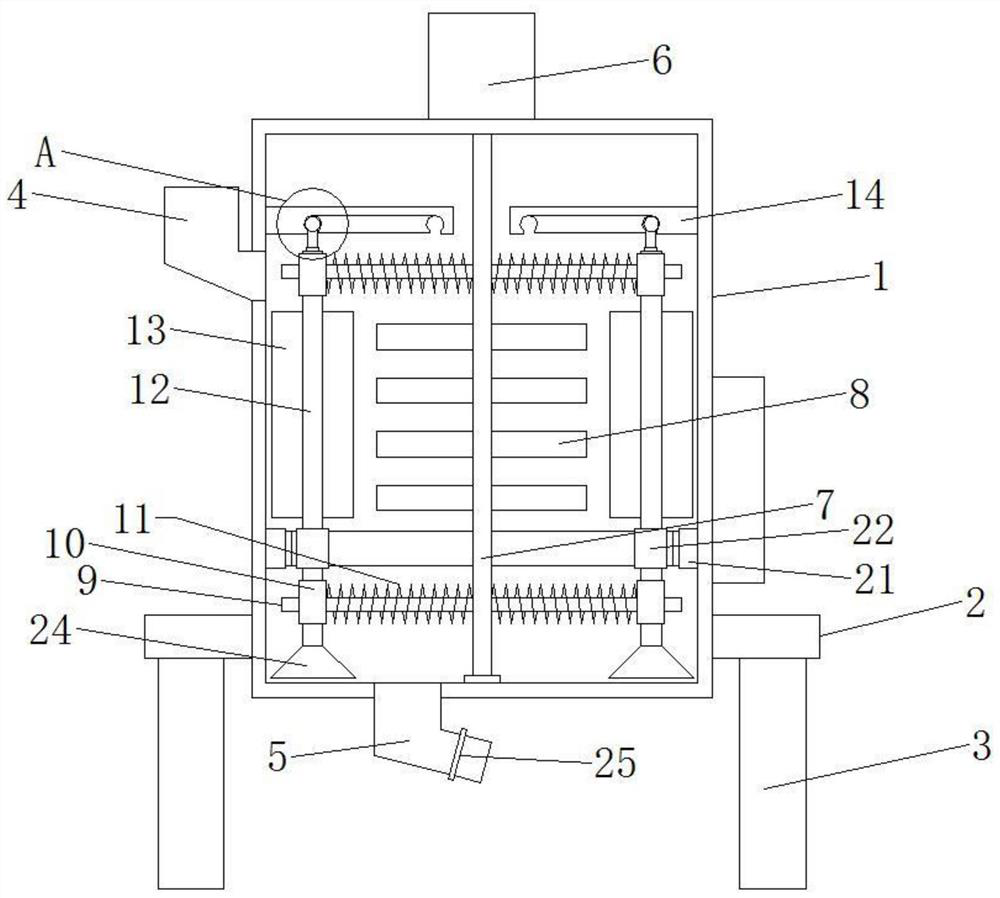

[0021] Please refer to the figure, in an embodiment of the present invention, a variable-diameter paint stirring and mixing device for construction includes a housing 1, a base 2, legs 3, a feed hopper 4, a discharge pipe 5, a motor 6 and a drive shaft 7 The base 2 is horizontally fixed on the bottom of the side wall of the housing 1, and the legs 3 are fixedly installed on the underside of the base 2 to support the housing 1; the top of the side wall of the housing 1 is connected with a feed hopper 4, Paint raw materials are loaded into the housing 1 from the feed hopper 4, and the bottom of the housing 1 is connected with a discharge pipe 5, and a valve 25 is installed on the discharge pipe 5, and the mixed paint is discharged from the discharge pipe 5. Tube 5 exits.

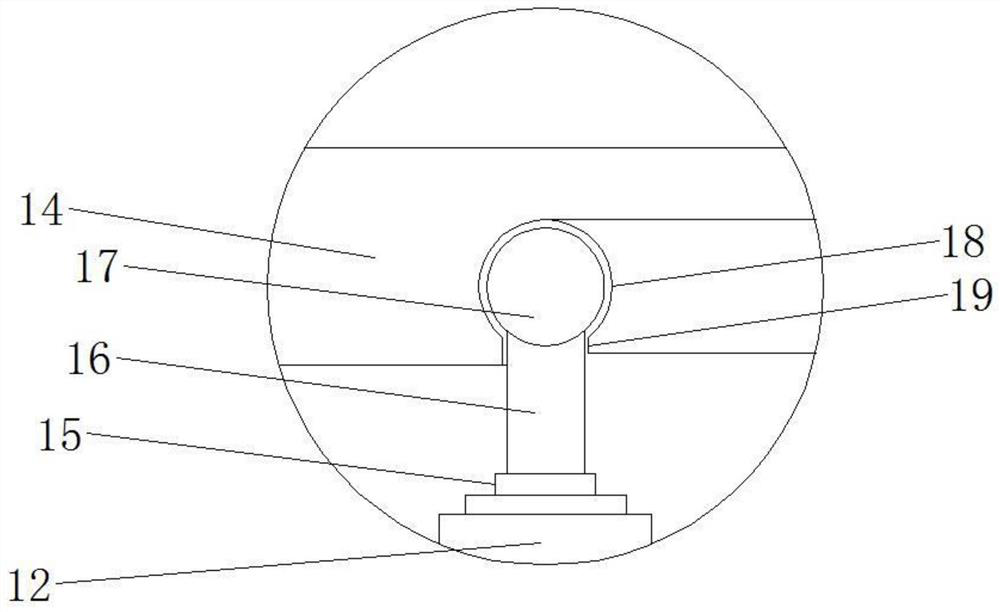

[0022] The motor 6 is coaxially fixed on the top of the housing 1, and the lower end of the output shaft of the motor 6 is coaxially fixedly connected with a vertical transmission shaft 7, and the lower end of...

Embodiment 2

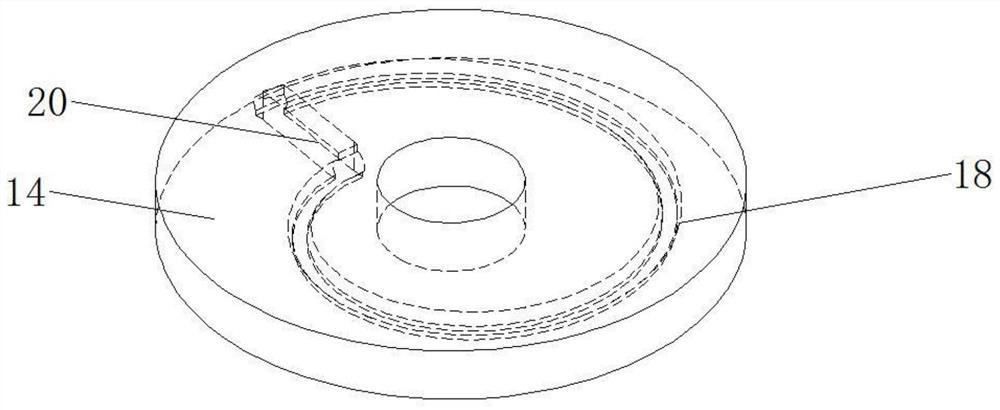

[0025] On the basis of Embodiment 1, a horizontal gear 22 is coaxially fixed on the outer side of the variable-diameter stirring shaft 12, and a lower guide plate 21 is fixedly installed on the inner wall of the housing 1 corresponding to the gear 22, and the inside of the lower guide plate 21 It is a hollow structure, and the shape of the inner wall corresponds to the vortex structure of the vortex chute 18. On the inner wall of the lower guide plate 21, a rack 23 meshing with the gear 22 is fixedly arranged. Rotate around the central axis during the movement of the shape structure to improve the stirring effect on the internal raw materials.

[0026]When in use, load the raw materials from the feed hopper 4 into the housing 1, start the motor 6, the motor 6 drives the transmission shaft 7 to rotate in the housing 1, and the main stirring blade 8 on the transmission shaft 7 stirs the raw materials inside Simultaneously, the transmission shaft 7 drives the support guide rod 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com