Optical fiber preform manufacturing apparatus and method for shrinkage and closing of deposited tube

A production device and production method technology, applied in optics, light guides, optical components, etc., can solve problems such as prolonged processing time, deformed geometric structure of deposition tubes, and decreased optical performance of finished optical fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

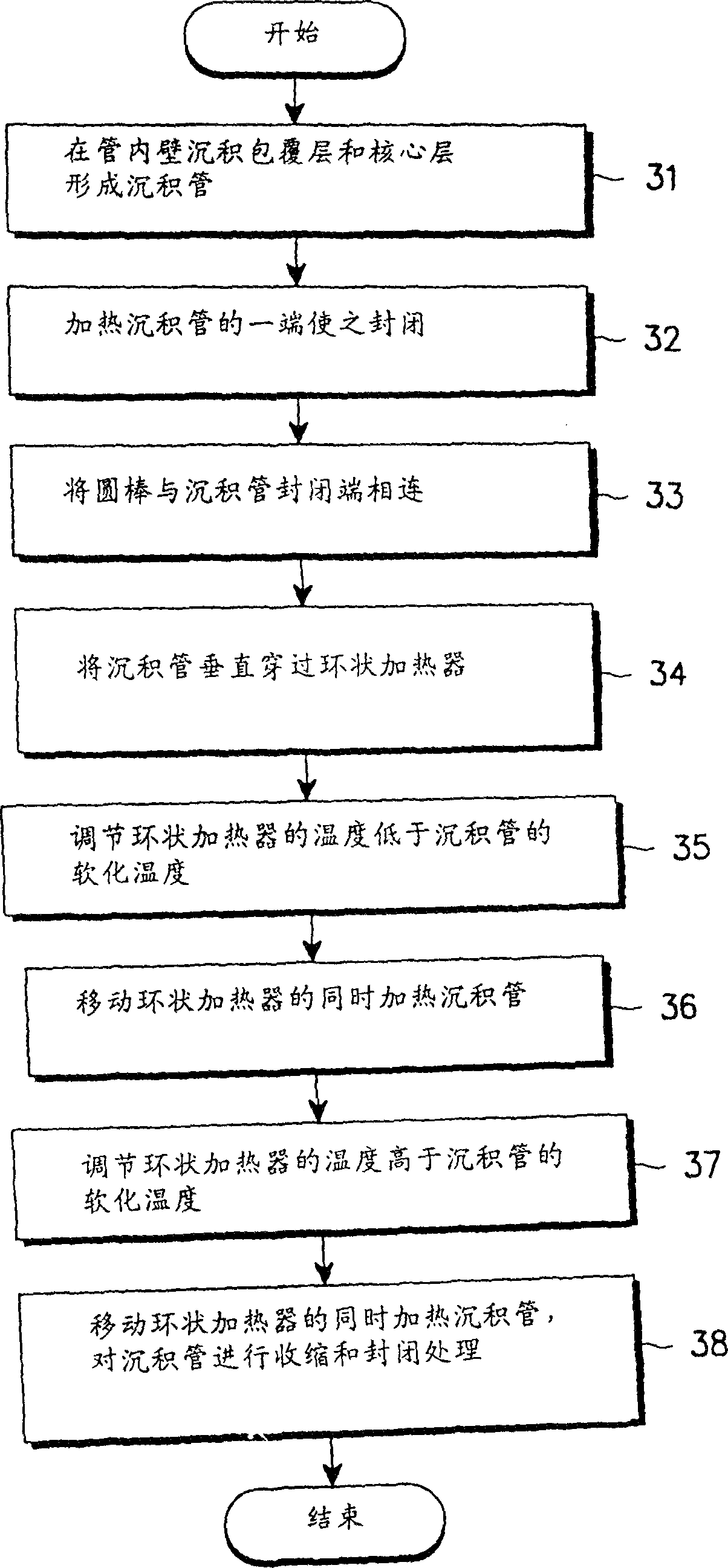

[0015] The invention discloses an optical fiber preforming production device and method, which comprises using the reaction product of raw material gas to deposit on the inner wall of a preforming tube to generate a deposition tube, and shrink and seal the deposition tube to obtain a preformed optical fiber . The deposition process is performed by an ordinary method such as the MCVD method. The shrinking and sealing process can be carried out simply and quickly by adopting the technology of the present invention.

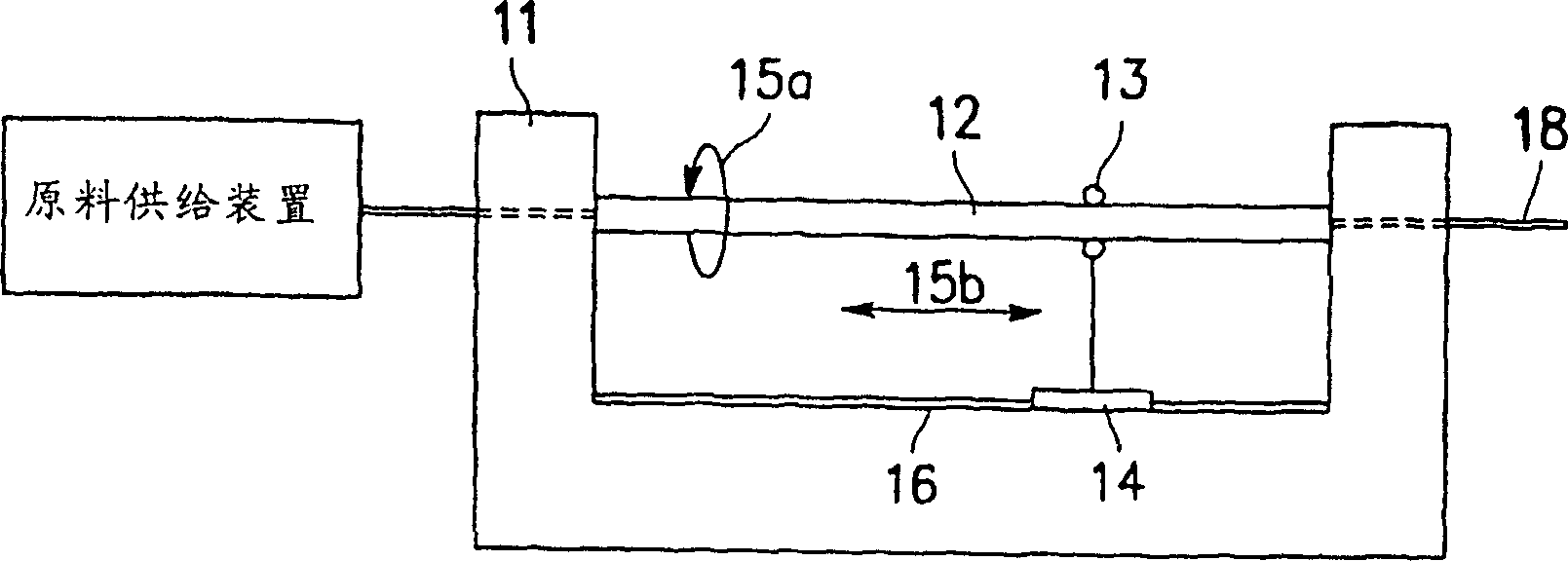

[0016] figure 1 is a general diagram of a deposition apparatus suitable for the MCVD method. The device is used to deposit the reaction product of the raw material gas on the inner wall of the preformed tube. see figure 1 , the lathe 11 is used to support the preformed tube 12 . Viewed in the longitudinal and radial directions, the heating device 14 locally heats the preformed tube 12 . exist figure 1 In , the area where the preformed tube is heated is indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com