A kind of rounding equipment for wood play cylinder blank

A cylinder and blank technology, which is applied to the field of rounding equipment for wooden play cylinder blanks, can solve the problems of cumbersome operation process, labor consumption, low work efficiency, etc., and achieve the effects of simple operation, improved work efficiency, and manpower saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

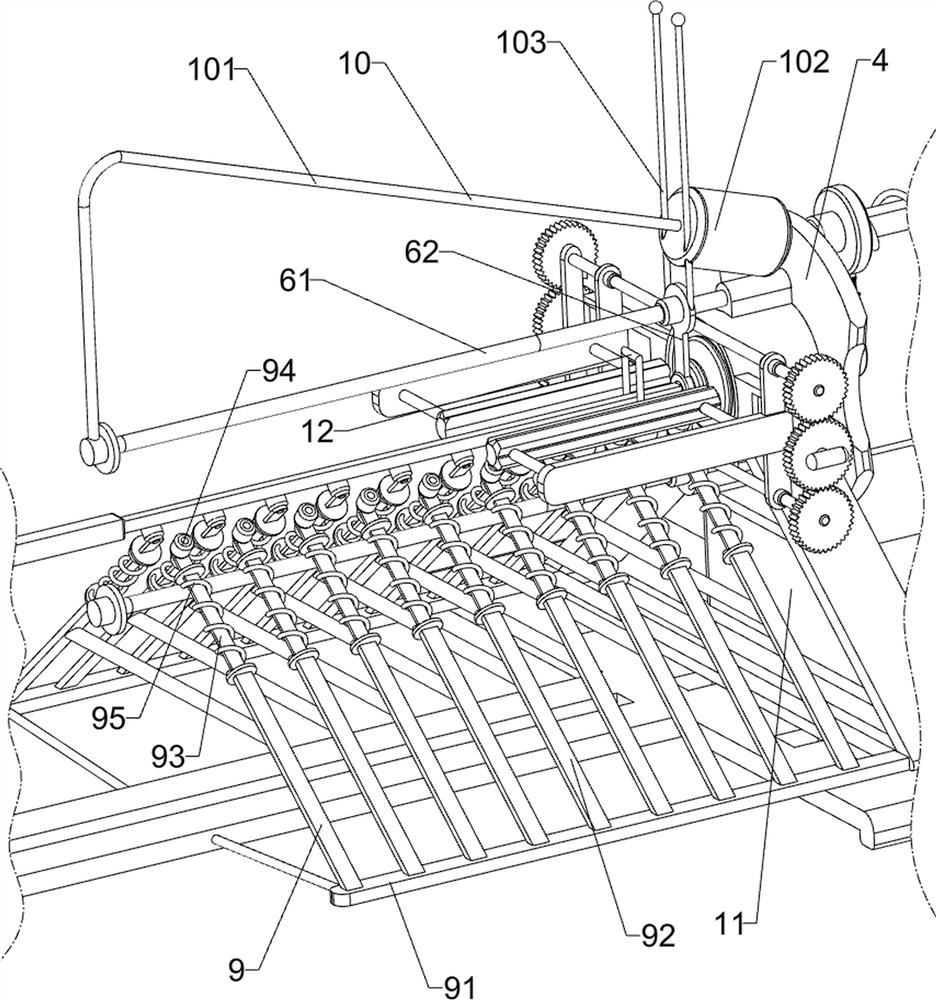

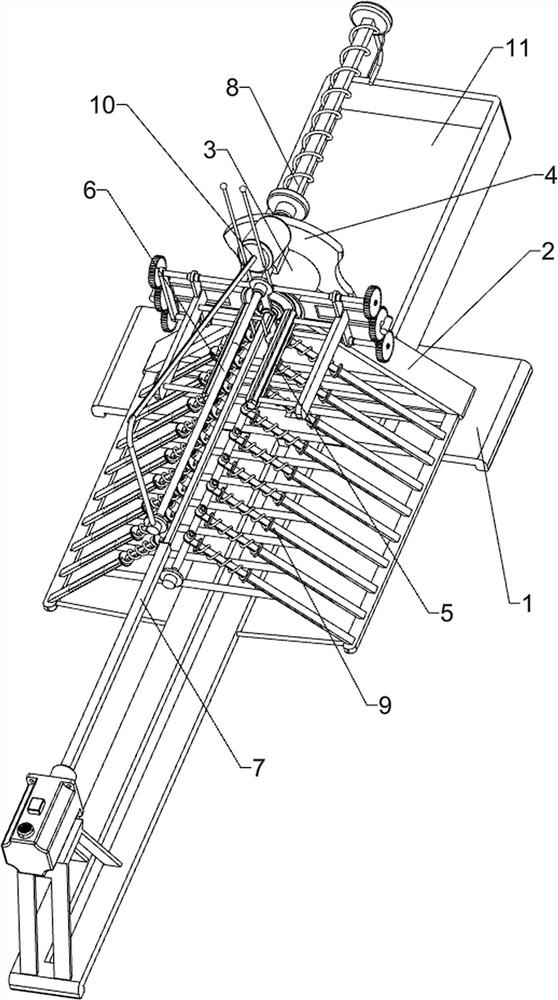

[0028] A wooden play cylindrical blank rounding equipment, such as Figure 1 to Figure 4 As shown, it includes a bottom plate 1, a wedge-shaped plate 2, a connecting sleeve 3 and a mounting plate 4. The left and right sides of the rear side of the top of the bottom plate 1 are connected with a wedge-shaped plate 2, and a connecting sleeve 3 is connected between the wedge-shaped plates 2 on both sides. The sleeve 3 is connected with a mounting plate 4, and also includes a rounding mechanism 5, a pushing mechanism 6, a transmission mechanism 7 and a clamping mechanism 8. The connecting sleeve 3 is provided with a rounding mechanism 5 and a pushing mechanism 6, and the bottom plate 1 is provided with A transmission mechanism 7, the transmission mechanism 7 is connected with the push mechanism 6 in transmission, and a clamping mechanism 8 is provided on the mounting plate 4.

[0029] The rounding mechanism 5 includes a sliding plate 51, a horizontal plate 52, a side plate 53, a bi...

Embodiment 2

[0035] On the basis of Example 1, as Figure 5 As shown, a support mechanism 9 is also included. The support mechanism 9 includes an abutment frame 91, an inclined plate 92, an inclined frame plate 93, a pulley 94 and a support spring 95. The base plate 1 is connected with abutment frame 91. The top of the abutment frame 91 is left and right. There are a plurality of inclined plates 92 connected on both sides evenly spaced. The inclined frame plate 93 is slidably connected to the inclined frame plate 92. The inclined frame plate 93 is rotatably connected with a pulley 94. The inclined frame plate 93 is connected to the inclined plate 92. A support spring 95 is connected therebetween.

[0036] When placing the cylindrical blank, the cylindrical blank will come into contact with the pulley 94, and the pulley 94 can hold up the cylindrical blank, so as to achieve the effect of holding the cylindrical blank, and the support spring 95 acts as a buffer.

Embodiment 3

[0038] On the basis of Example 2, as Figure 5 As shown, a sliding mechanism 10 is also included. The sliding mechanism 10 includes a connecting rod 101, a gravity slider 102 and a vertical rod 103. A connecting rod 101 is connected between the front side of the mounting plate 4 and the upper sliding rod 61. The connecting rod 101 A gravity slider 102 is slidably connected to the upper side, and vertical rods 103 are connected to both sides of the top of the push plate 62 , and the vertical rods 103 are slidably matched with the gravity slider 102 .

[0039] When the push plate 62 needs to be pulled to move, the gravity slider 102 can be pulled to move along the connecting rod 101. When the gravity slider 102 moves, the push plate 62 is pulled forward by the vertical rod 103. After the cylindrical blank is placed, it can be released. The gravity slider 102, the gravity slider 102 moves backward along the connecting rod 101 under the action of gravity, and the gravity slider 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com