Extrusion equipment capable of realizing screw online separation

A technology of extrusion equipment and screw, which is applied in the field of extrusion equipment, can solve the problems of affecting the extrusion effect of materials and large particles, and achieve the effect of facilitating uniform turning, avoiding material accumulation, and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

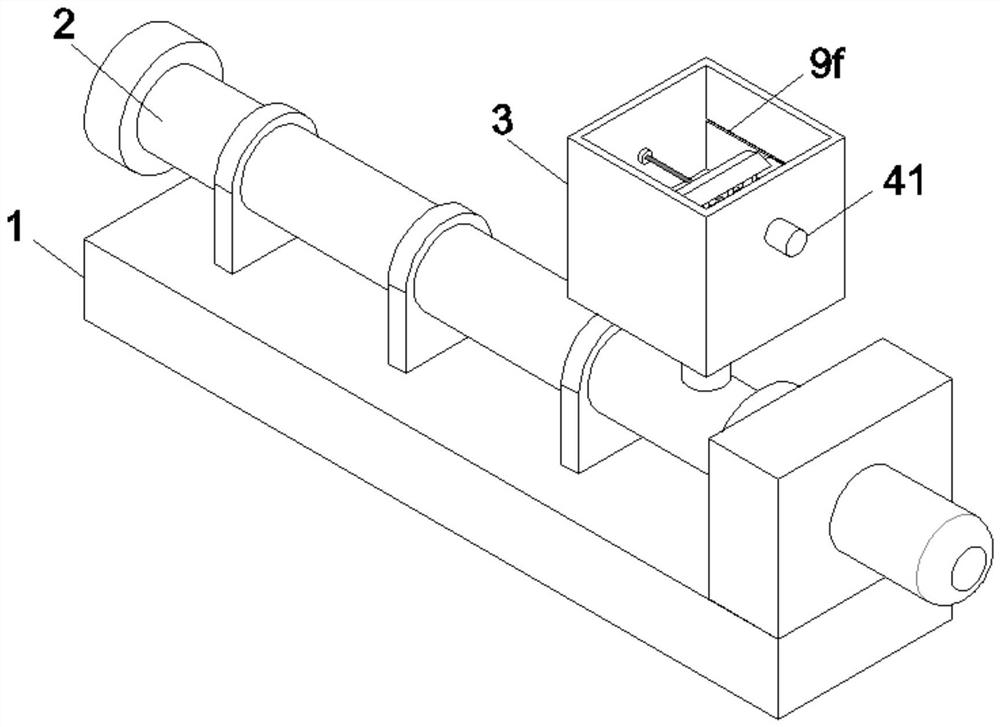

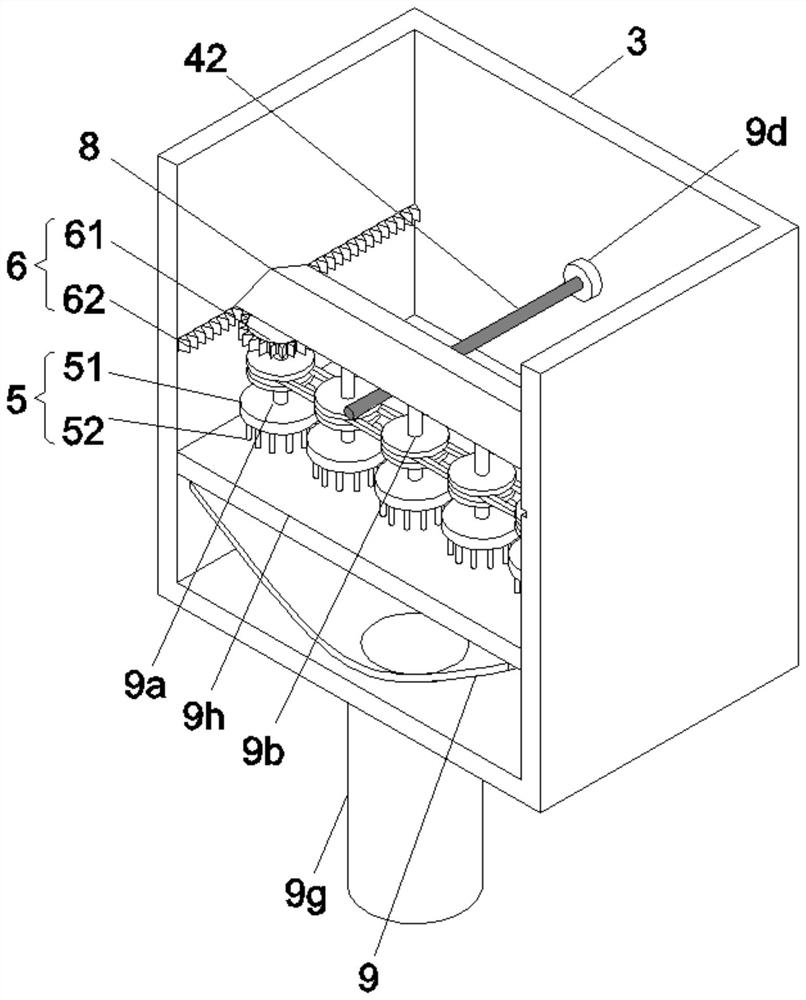

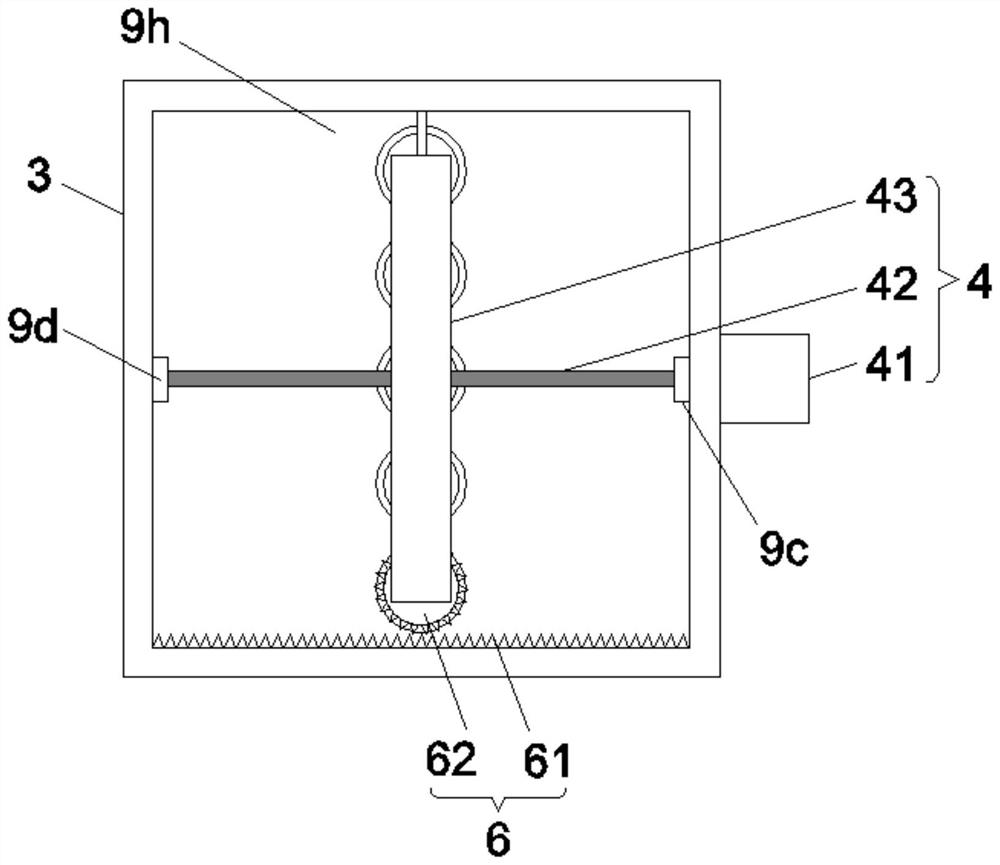

[0023]Please refer tofigure 1 ,figure 2 ,image 3 withFigure 4,among them,figure 1 It is a schematic structural diagram of a preferred embodiment of the extrusion equipment that can realize on-line screw separation provided by the present invention;figure 2 forfigure 1 The structure diagram of the feeding box shown;image 3 forfigure 1 The top view of the feeding box shown;Figure 4forfigure 2 The schematic diagram of the split structure shown. Extrusion equipment that can realize screw online separation includes: base 1, moving mechanism 4, rotating mechanism 6, flipping mechanism 5 and linkage mechanism 7. The top of base 1 is fixedly installed with barrel 2, and the top of barrel 2 is fixedly installed with feed A feeding box 3 is fixedly installed on the top of the tube 9g and the feeding tube 9g, and a sieve plate 9h is fixedly installed on the inner side wall of the feeding box 3.

[0024]In the specific implementation process, such asfigure 2 withFigure 4As shown, the moving mechan...

Embodiment 2

[0038]On the basis of Example 1, the applicant found in practice that when more materials are poured into the feeding box 3, the speed of the materials passing through the screen 9h is greatly reduced, and at the same time, due to the stickiness of the materials, blockage of block materials, etc. The reason greatly affects the screening efficiency. Therefore, in this implementation, the horizontal plate 43 is set as a cavity structure, and an air pump is installed on one side of the horizontal plate 43. The air outlet of the air pump is connected with the cavity inside the horizontal plate 43, and the turntable 51 is turned over The inside of the rod 52 is provided with a cavity structure, and the turntable 51 is connected with the cavity in the flipping rod 52, the bottom of the flipping rod 52 is provided with an air outlet, the first rotating rod 9a and the second rotating rod 9b are provided with through holes, and The cavity in the horizontal plate 43 and the cavity in the turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com