Molten aluminum slag removing device in aluminum alloy machining and using method thereof

A technology of aluminum alloy and aluminum liquid, which is applied in the field of aluminum alloy processing equipment, can solve the problems of inability to realize high-efficiency slag removal of aluminum liquid, inability to evenly sprinkle and separate slag-forming agents, etc., to facilitate collection and centralized cleaning, and realize left-right adjustment , to achieve the effect of fixing and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

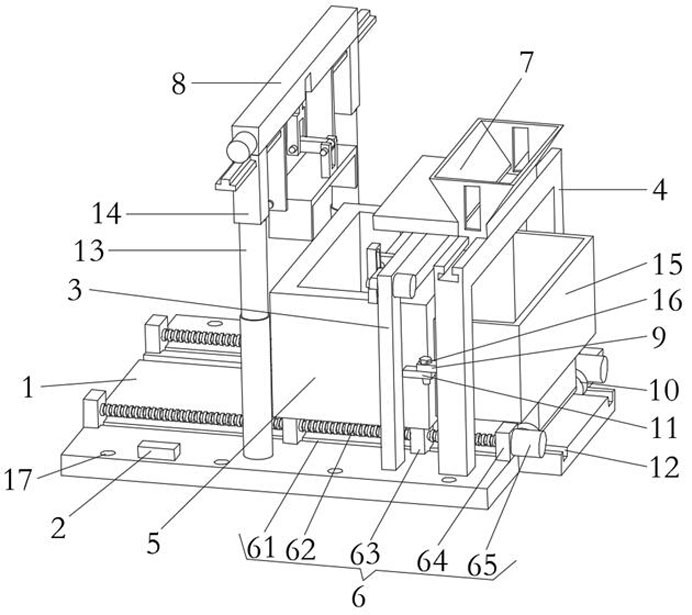

[0027] A liquid aluminum slag removal device in aluminum alloy processing, comprising a base plate 1, an adjustment structure 6, a blanking structure 7 and a slag removal structure 8, the upper surface of the base plate 1 is symmetrically provided with uniformly distributed installation holes 17 at the front and rear ends, and the base plate 1 The first U-shaped frame 3 and the second U-shaped frame 4 are respectively arranged on the left side of the upper surface, the first U-shaped frame 3 is located on the left side of the second U-shaped frame 4, and the middle part of the upper surface of the bottom plate 1 is symmetrically provided with electric push rods 13. The upper end of the telescopic end of the electric push rod 13 is equipped with a vertical plate 14, which is connected to the installation part through the installation hole 17 by bolts, so as to realize the installation and fixation of the bottom plate 1 and the structure above it. The first U-shaped frame 3 and th...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is:

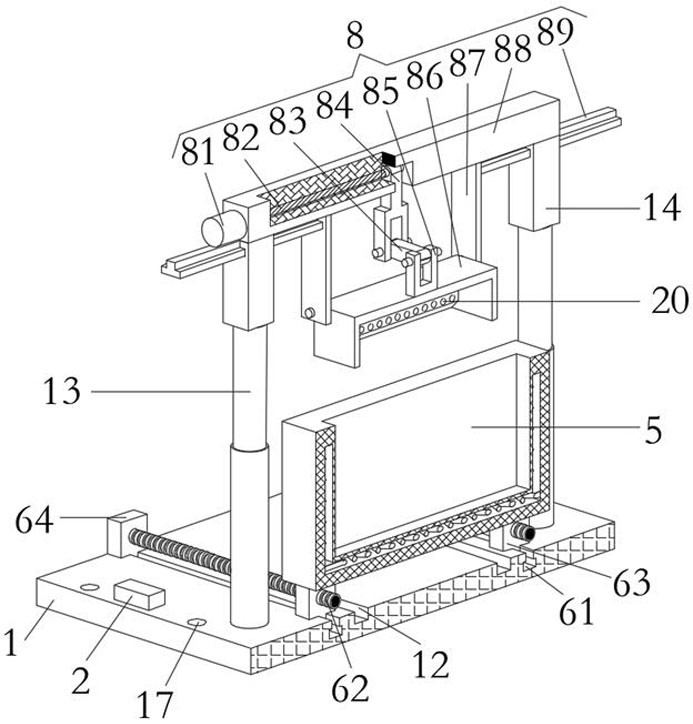

[0031] In this embodiment, the adjustment structure 6 includes a first chute 61, a screw rod 62, a slider 63, a square plate 64, and a first motor 65. The square plate 64 is symmetrically arranged on the left and right sides of the upper surface of the bottom plate 1, and the right side The right sides of the square plates 64 are all provided with a first motor 65, and the horizontally corresponding square plates 64 are connected with a screw mandrel 62 through bearing rotation, and the right ends of the screw mandrels 62 are respectively output by the corresponding first motor 65 through a coupling. The left end of the shaft is fixedly connected, and the upper surface of the bottom plate 1 is symmetrically provided with a first chute 61, and the inside of the first chute 61 is slidably connected with a slider 63, and the threaded holes at the upper end of the slider 63 are respectively threaded with the corre...

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is:

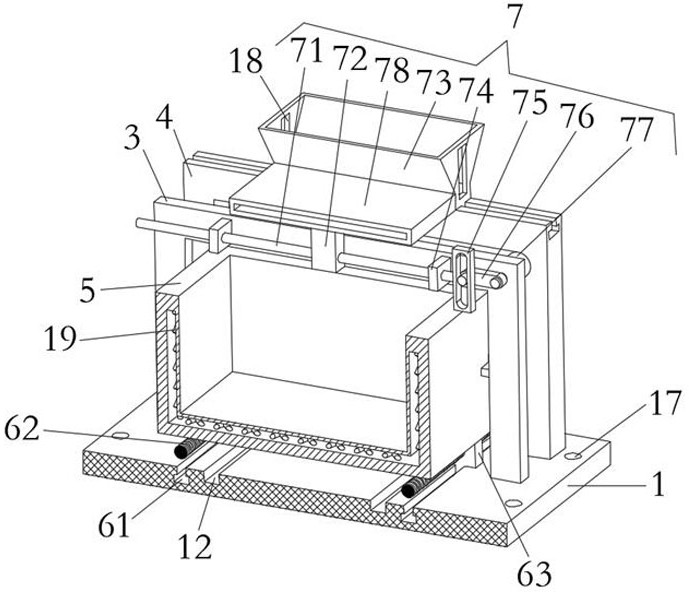

[0035] In this embodiment, the blanking structure 7 includes a round rod 71, a fixed block 72, a funnel 73, a support block 74, a square frame 75, a swing rod 76, a second motor 77 and a diversion groove 78, and the second motor 77 is arranged on the second motor 77. The front end of the horizontal plate body right side of a U-shaped frame 3, the output shaft of the second motor 77 is connected with the plate body through hole of the first U-shaped frame 3 through the bearing and extends to the left side of the first U-shaped frame 3, The end of the output shaft of the second motor 77 is provided with a swing lever 76, and the slider at the lower end of the funnel 73 is slidably connected with the chute on the upper surface of the second U-shaped frame 4, and the opening at the lower end of the left side of the funnel 73 is provided with a diversion groove 78 , the lower end of the left side bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com