Grinding device for cold-formed section steel and working method of grinding device

A cold-formed steel and grinding head technology, which is used in grinding drive devices, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problem of injury to workers, easy sparks to splash on the workers, and insufficient hand-held grinding parts. Stability and other issues, to achieve the effect of left and right adjustment, improving stability, and stabilizing front and rear adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

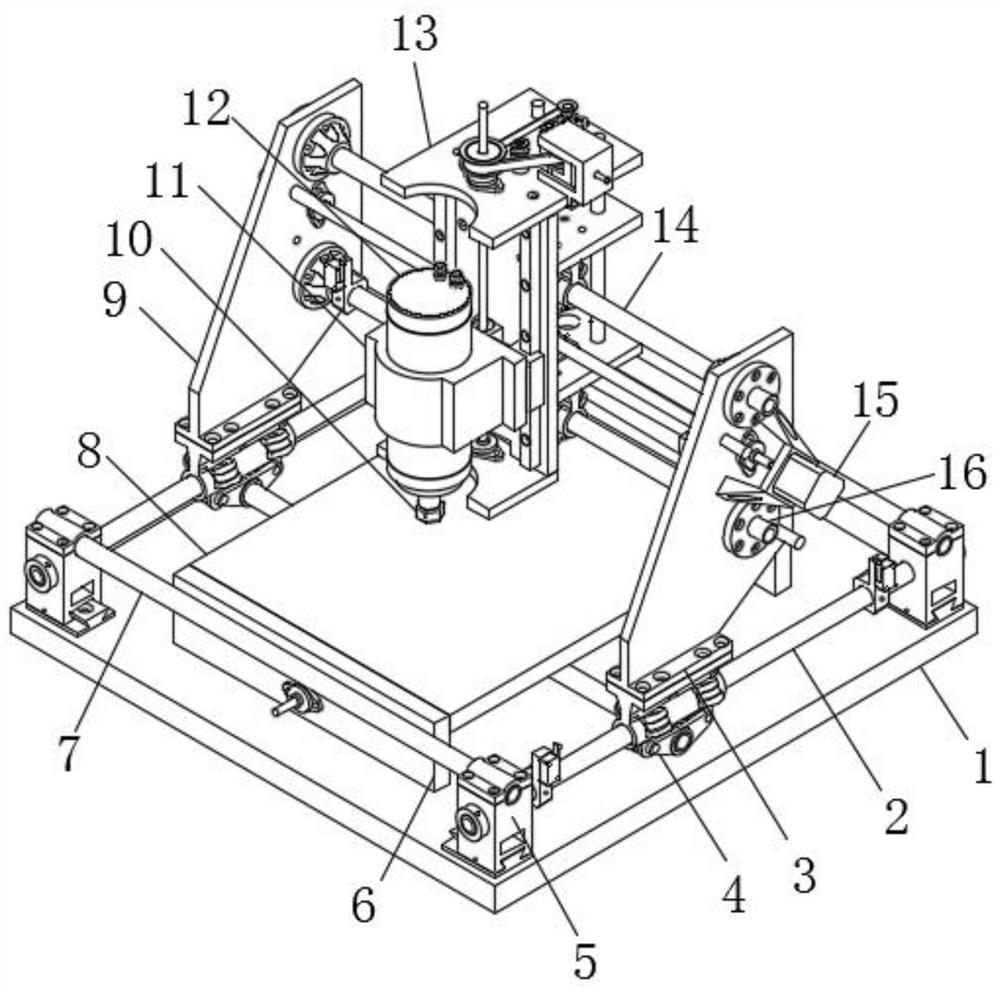

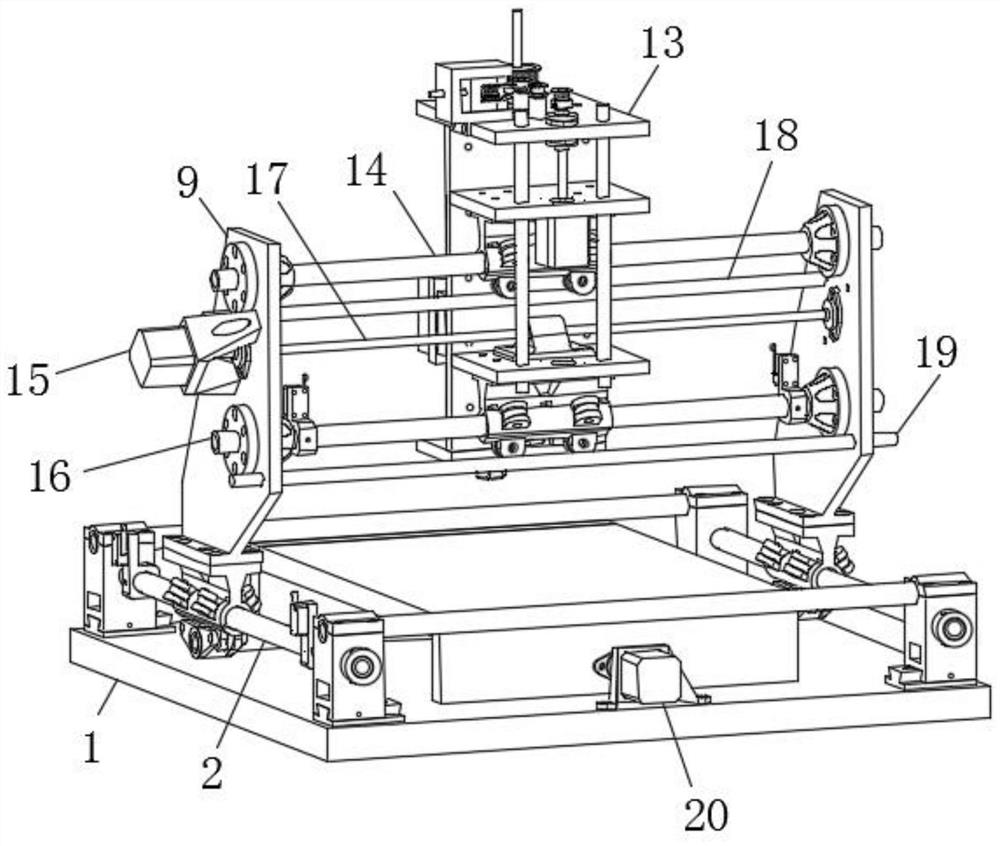

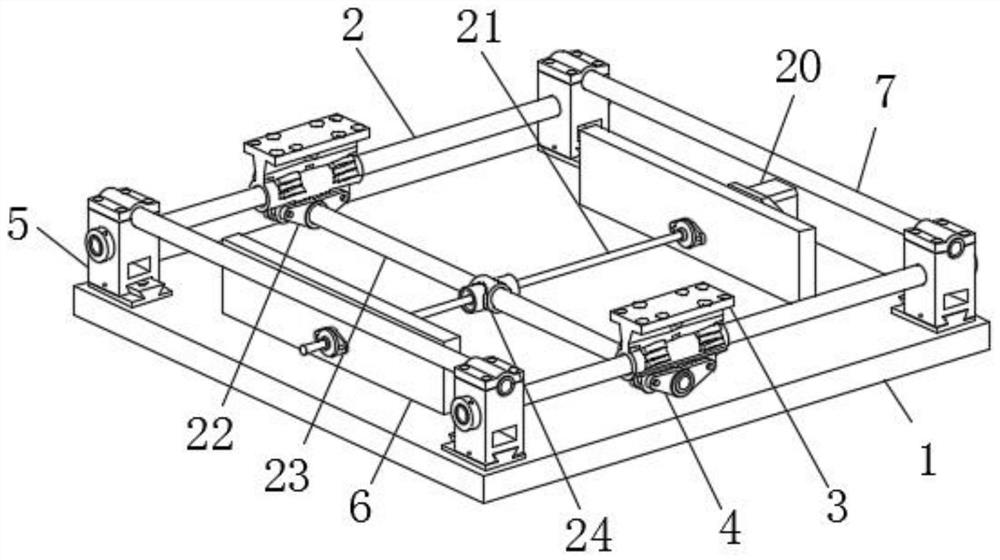

[0039] see Figure 1-9 As shown, a grinding device for cold-formed steel includes a base 1, a fixed plate 6, a workbench 8, a grinding head 10 and a grinding motor 12, and a fixed plate 6 is symmetrically installed on both sides of the upper end surface of the base 1, and the outer side of the fixed plate 6 and The upper end of the base 1 is equipped with a second adjusting motor 20, the output end of the second adjusting motor 20 is connected with a second screw 21, and the end of the second screw 21 away from the second adjusting motor 20 passes through the fixing plate 6, and the inside of the fixing plate 6 is installed There is a workbench 8, a vertical plate 25 is installed above the worktable 8, an upper top plate 13 is installed on the upper end of the vertical plate 25, and a lower bottom plate 28 is installed on the lower end of the vertical plate 25;

[0040] One side of vertical plate 25 is equipped with upright bar 26, and on the upright bar 26, sliding block 30 i...

Embodiment 2

[0050] A working method of a grinding device for cold-formed steel, the working method of the grinding device for cold-formed steel specifically includes the following steps:

[0051] Step 1: The cold-formed steel to be polished is placed on the workbench 8, the second adjusting motor 20 is energized to drive the second screw 21 to rotate, the second screw 21 meshes with the moving cross bar 23 through the screw hole, and the second screw 21 drives the movement The cross bar 23 moves, and the two ends of the moving cross bar 23 are fixed to the sliding seat 4 through the inner connecting seat 22, and then the sliding seat 4 is driven to slide along the longitudinal bar 2, because the side plate 9 is connected to the sliding seat 4 through the upper connecting seat 3 Fixing, so that the side plate 9, the grinding motor 12, the grinding head 10, and the vertical plate 25 are adjusted back and forth along the longitudinal bar 2 as a whole;

[0052] Step 2: Adjust the grinding hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com