Super-soft composite yarn and application thereof

A composite yarn, ultra-soft technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of limited application scope, inconsistent color absorption, bone stiffness in the core, etc., to achieve extended application scope, excellent comfort, fineness wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of supersoft composite yarn and its application on clothing

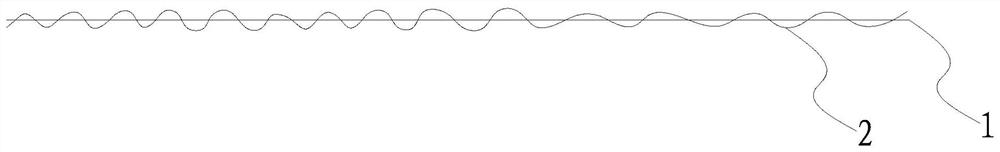

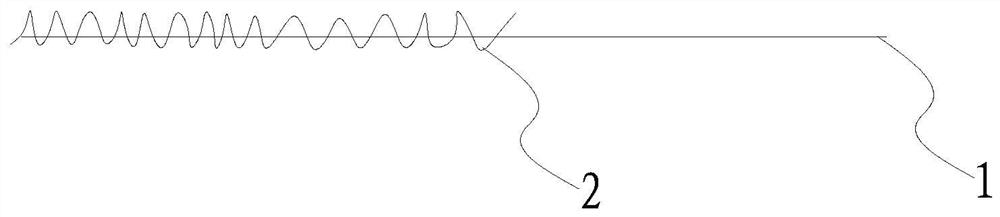

[0038] In weight percent, the ultra-soft composite yarn provided by the present embodiment is made of 50% high-shrinkage polyester monofilament as the core layer, and 50% normal-temperature cationic polyester with ordinary shrinkage is used as the cortex. The specification of the high-shrinkage polyester monofilament is 30D, and the shrinkage The shrinkage rate is 30%, and the normal temperature cationic polyester with ordinary shrinkage has a specification of 70D, and the shrinkage rate is 7%. The cortex is evenly wrapped around the core layer in the form of loops to form a composite yarn before dyeing and finishing, such as figure 1 shown. After conventional dyeing and finishing processes such as bleaching, washing, drying, preheating and setting, dyeing, drying and heat setting, inspection and packaging, such as figure 2 Shown is the supersoft composite yarn described in this example...

Embodiment 2

[0041] Embodiment 2 A kind of supersoft composite yarn and its application in bedding

[0042]The difference from Example 1 is that, in terms of weight percentage, the supersoft composite yarn provided by this embodiment is made of 40% high-shrinkage polyester monofilament as the core layer, and 60% normal-temperature cationic polyester with ordinary shrinkage as the skin layer, and the high-shrinkage polyester monofilament is used as the skin layer. The specification of polyester monofilament is 50D, and the shrinkage rate is 33%.

[0043] The ultra-soft composite yarn described in this example was tested for fracture, the breaking strength was 341cN, the breaking elongation was 148.3mm, the breaking elongation was 29.44%, the breaking strength was 3.82cN / dtex, and the breaking work was 36.90N*cm .

[0044] The ultra-soft composite yarn described in this example is used to produce the outer surface of the pillow cover, and the soft touch is obviously improved through the tou...

Embodiment 3

[0045] Embodiment 3 A kind of supersoft composite yarn and its application on thermal products

[0046] The difference from Example 1 is that, in terms of weight percentage, the supersoft composite yarn provided by this example is made of 45% high-shrinkage polyester monofilament as the core layer, and 55% normal-temperature cationic polyester with ordinary shrinkage as the skin layer, and the high-shrinkage The specification of polyester monofilament is 400D, and the shrinkage rate is 35%. The specification of ordinary shrinkage normal temperature cationic polyester is 400D, and the shrinkage rate is 7%.

[0047] The ultra-soft composite yarn described in this example was tested for fracture, the breaking strength was 342cN, the breaking elongation was 148.5mm, the breaking elongation was 29.47%, the breaking strength was 3.83cN / dtex, and the breaking work was 38.78N*cm .

[0048] The ultra-soft composite yarn described in this example is used to produce a scarf, and the sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com