Double-layer magnetic shielding type rectangular eddy current sensor

An eddy current sensor, magnetic shielding technology, applied in the direction of instruments, scientific instruments, material magnetic variables, etc., can solve the problems of poor lateral sensitivity and weak detection signal, and achieve the effect of reducing loss, improving detection signal strength, and high lateral sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the following examples are only descriptive and not restrictive, and cannot be used to limit the protection scope of the present invention.

[0033] Based on the principle of magnetic shielding and electromagnetic induction, a double-layer magnetic shielding rectangular eddy current sensor is designed. Using this sensor to detect groove defects on the surface of stainless steel plates, it can obtain higher detection signal strength and higher detection signal strength than conventional eddy current sensors. Lateral detection sensitivity.

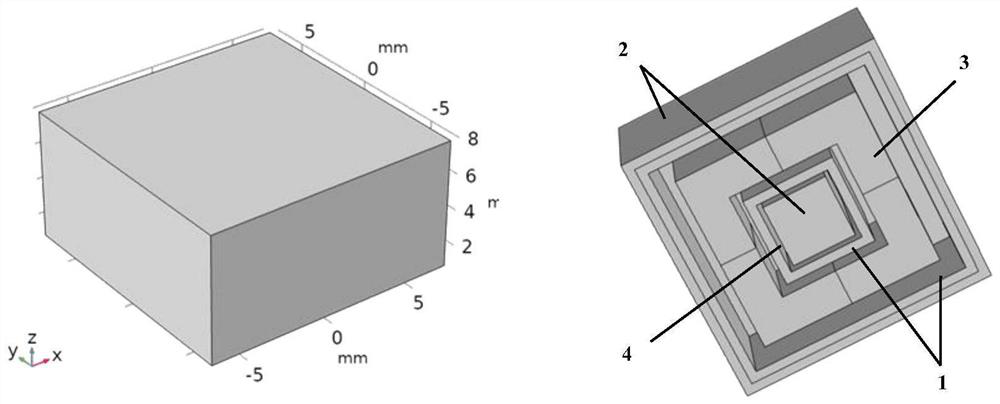

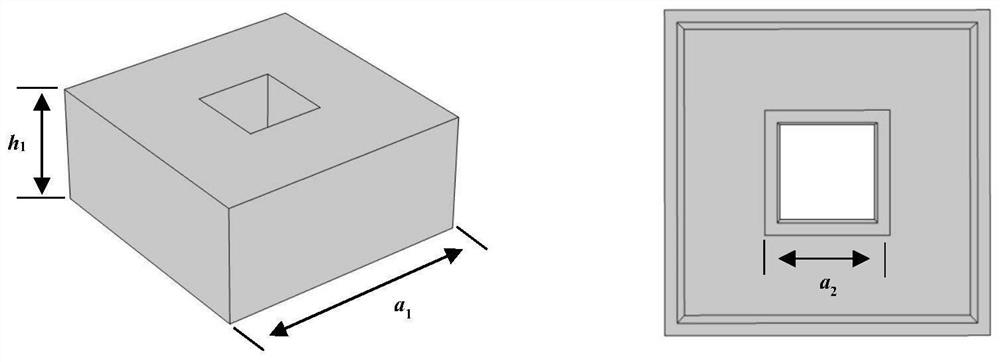

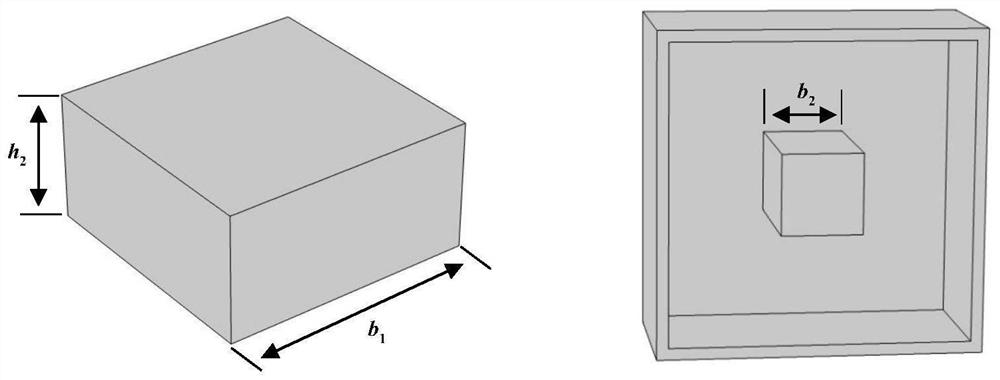

[0034] The structure diagram of the double-layer magnetically shielded rectangular eddy current sensor is figure 1 shown. The sensor includes an inner shielding shell 1 , an outer shielding shell 2 , a rectangular exciting coil 3 and a rectangular receiving coil 4 . The detection object is a stainless steel plate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com