Pump laser packaging structure and packaging method

A technology for pumping lasers and packaging structures, which is applied in laser devices, semiconductor laser devices, lasers, etc., and can solve problems such as heat generation and inability to completely absorb light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

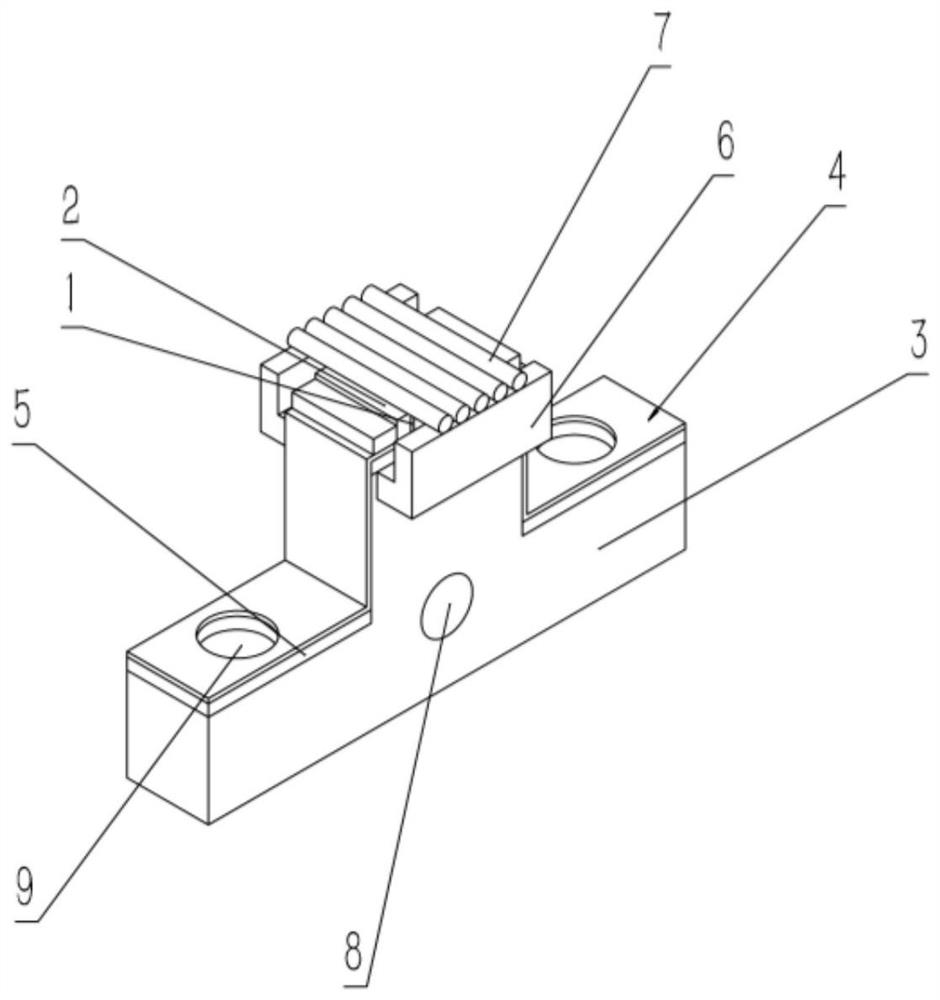

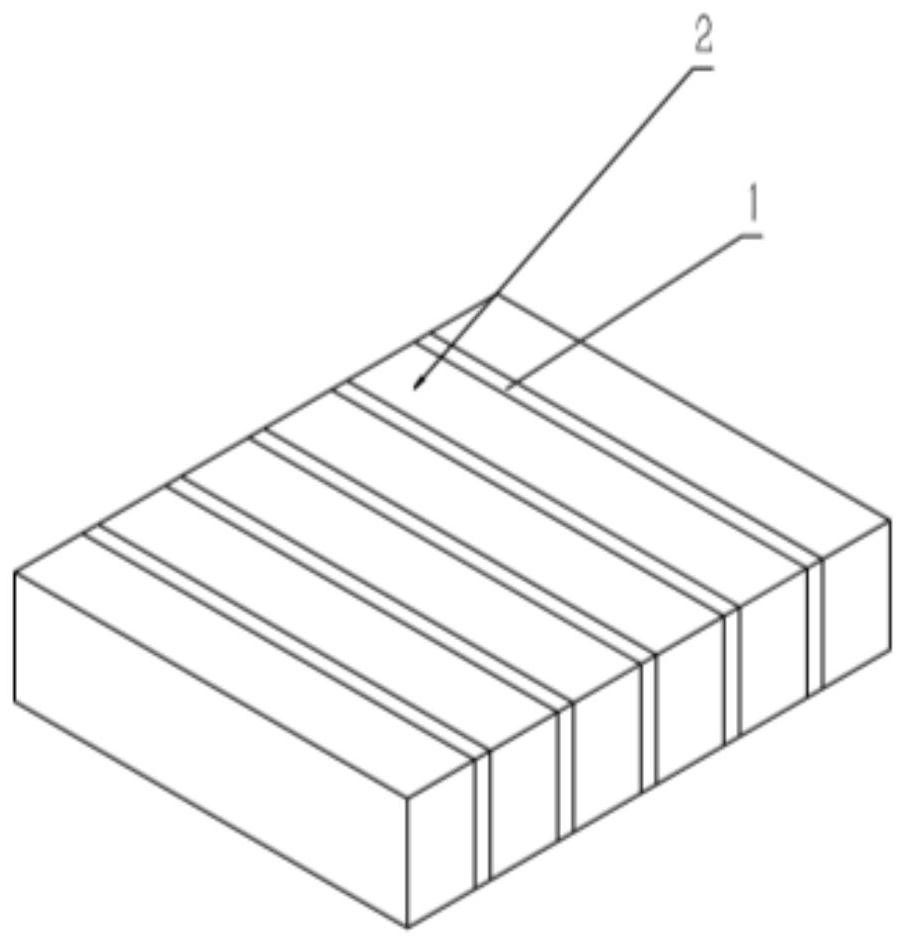

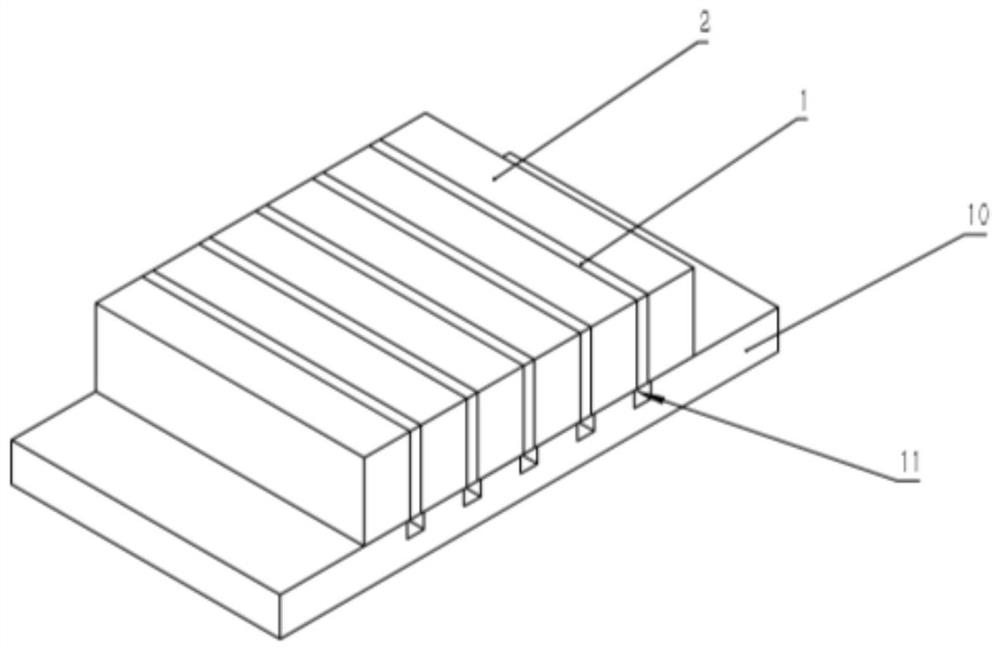

[0036] Such as Figure 1-4 As shown, a pump laser package structure, including mini bar 1, tungsten copper heat sink 2, AlN ceramic sheet 10, heat dissipation heat sink 3 and electrode 4, mini bar 1 and tungsten copper heat sink 2 are welded to form a bar arrays, such as figure 2 As shown, the thickness of the tungsten-copper heat sink 2 is 0.3 mm, the length of the mini bar 1 is 3 mm, and the length of the mini bar is consistent with the length of the tungsten-copper heat sink. 4 is packaged to both ends of the heat dissipation heat sink through the electrode insulating sheet 5 . The length of the tungsten copper heat sink 2 is the same as the length of the mini bar. Considering the stress release and heat dissipation capability, W90Cu with a thermal conductivity of 188W / (m*K) and a CTE of 6.5ppm / K is selected as the tungsten copper heat sink material. The coefficient of thermal expansion (CTE) is basically the same as that of the bar material, ensuring stress relief durin...

Embodiment 2

[0039] A packaging structure for a pump laser, the structure is as described in Embodiment 1, the difference is that the thickness of the tungsten-copper heat sink 2 is 10 mm, and the length of the mini bar is 1 mm.

Embodiment 3

[0041] A pump laser packaging structure, the structure is as described in Embodiment 1, the difference is that the lens 7 is installed above the bar array, the lens is fixed by the spacer 6, the spacer 6 is fixed on the upper end of the heat sink 3, and the spacer The cross-section is L-shaped, and the number of pads is two. The two pads are symmetrically arranged on both sides of the upper end of the heat sink. The upper surface of the pads is parallel to the upper surface of the tungsten copper heat sink. A lens is arranged between the two pads. The lens 7 is an O-shaped cylindrical lens, which can be used for compression in the direction of the fast axis of the bar to obtain pump light with high beam quality. The lens 7 is used to focus and homogenize the light spot, so that the energy distribution of the laser is more concentrated and uniform, and the laser energy distribution is improved. The beam quality of the pump light improves the pump efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com