Oil film vortex motion and friction concurrent fault analysis method and analysis system

A fault analysis method and whirl technology, applied in the direction of instruments, character and pattern recognition, computer parts, etc., can solve the problems of easy misdiagnosis, incomplete feature extraction, difficulty in feature extraction, etc. Sufficient and comprehensive, good effect of gear failure prediction problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

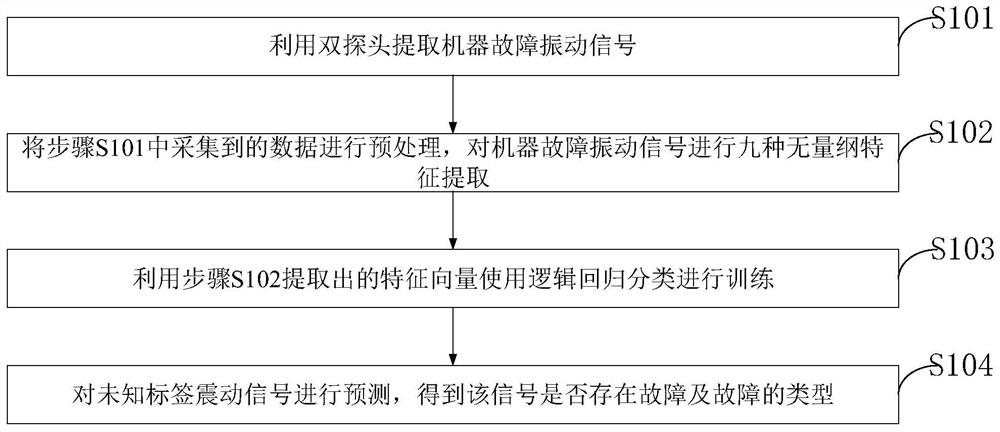

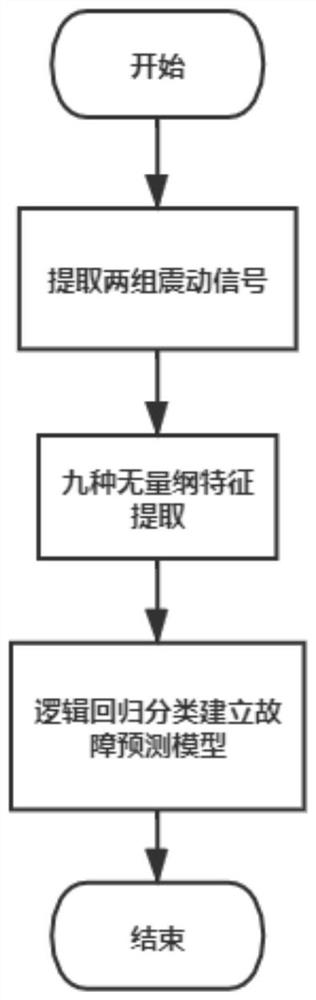

[0083] Such as figure 2 As shown, the present invention provides a method for analyzing oil film whirl and friction concurrent faults based on nine dimensionless feature extraction and logistic regression classification, including:

[0084] Step 1, using dual probes to extract machine fault vibration signals;

[0085] Step 2, preprocessing the data collected in step 1, and extracting nine dimensionless features from the machine fault vibration signal;

[0086] Step 2.1, through the method of sliding window, set the window size and sliding step according to the amount of data, each window is a sample, and extract the feature value of each window.

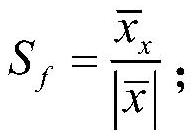

[0087] Step 2.2, calculate the dimensionless characteristic wave index S f , taking the wave index as one of the extracted features, the specific calculation formula is as follows:

[0088]

[0089] in Indicates the root mean square value of the waveform data, Indicates the absolute average of waveform data;

[0090] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com