Hydraulic practical training device and practical training method

A training device and training technology, which is applied to the simulation device of space navigation conditions, transportation and packaging, instruments, etc., can solve the problems of oil pollution, pungent demonstration board and card slot, difficult sliding of hydraulic training equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

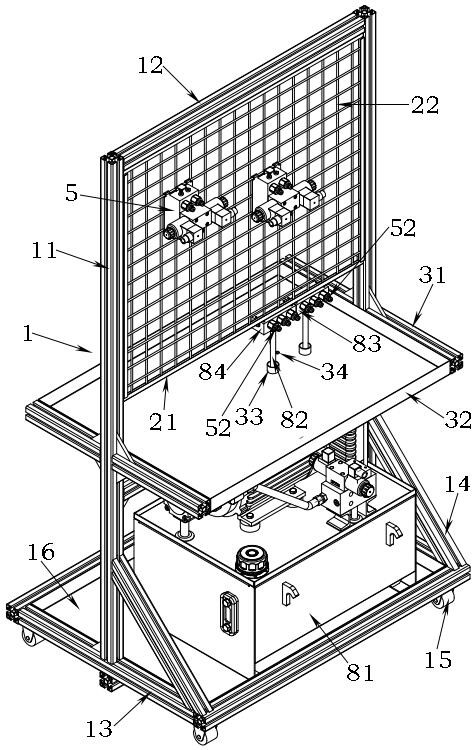

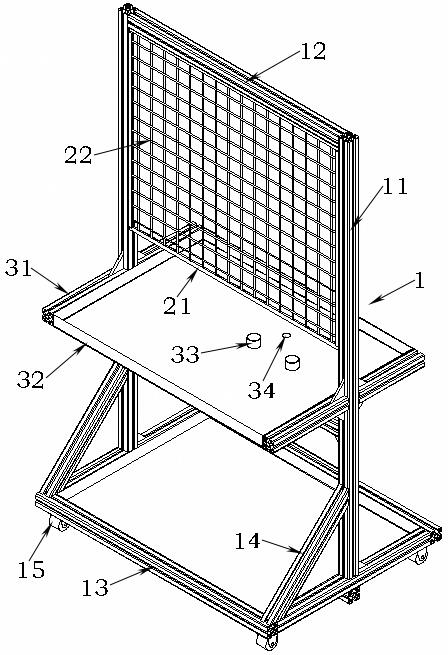

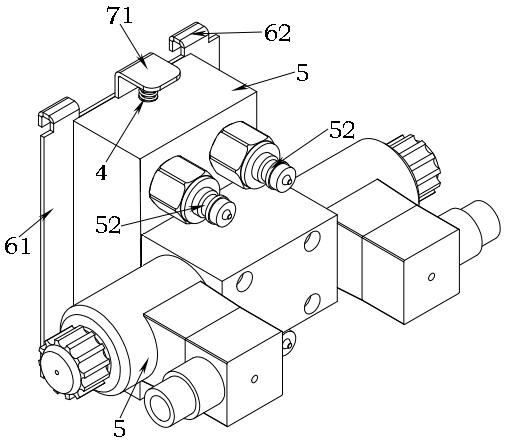

[0029] Such as figure 1 and figure 2 As shown, the hydraulic training device includes a training frame 1, a hydraulic mechanism and a suspension device, and the training frame 1 includes a support rod 11, a push rod 12, a bottom frame rod 13, a side rod 14 and a roller 15, and the bottom frame rod 13 is arranged on The lower end of the training frame 1, the bottom frame bar 13 surrounds a hollow rectangular shape, and the loading tray 16 is installed on the bottom frame bar 13. Both sides of the bottom frame rod 13 are provided with support rods 11, the bottom frame rod 13 is vertically connected with the support rod 11, and the two ends of the side rod 14 are respectively connected with the bottom frame rod 13 and the support rod 11. The two ends of the ejector rod 12 are respectively connected with the tops of the two support rods 11, the support rods 11 are also provided with a stabilizing rod 31, and the oil pan 32 is mounted on the stabilizing rod 31.

[0030] The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com