A kind of method for hanging safety belt for underground continuous wall

A technology for underground diaphragm walls and safety belts, applied in sheet pile walls, construction material processing, construction, etc., can solve problems such as hidden safety hazards, difficulty in safety management work, and large chiseled areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

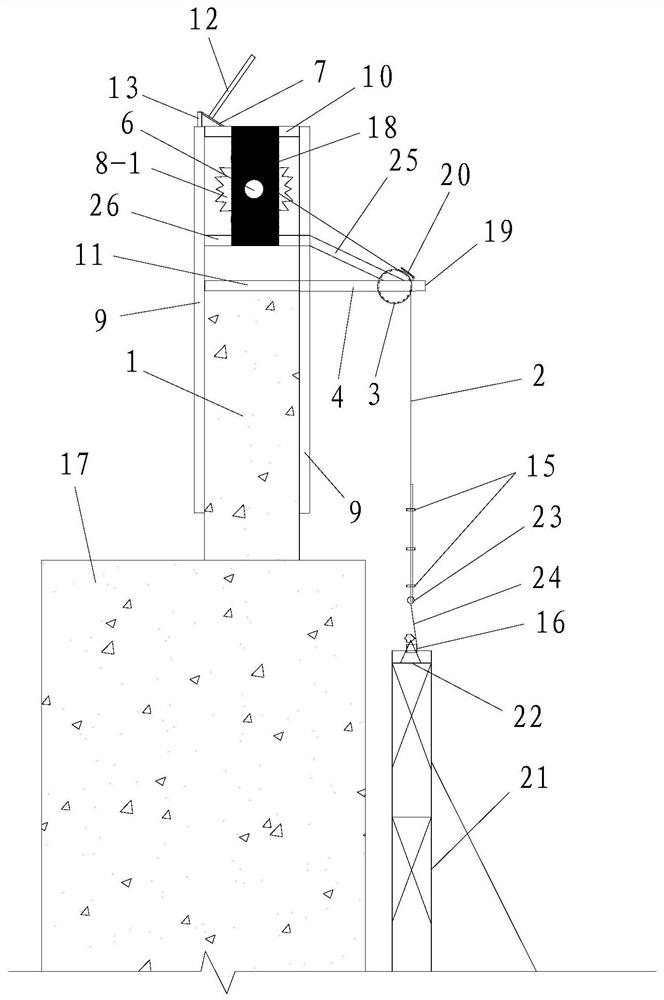

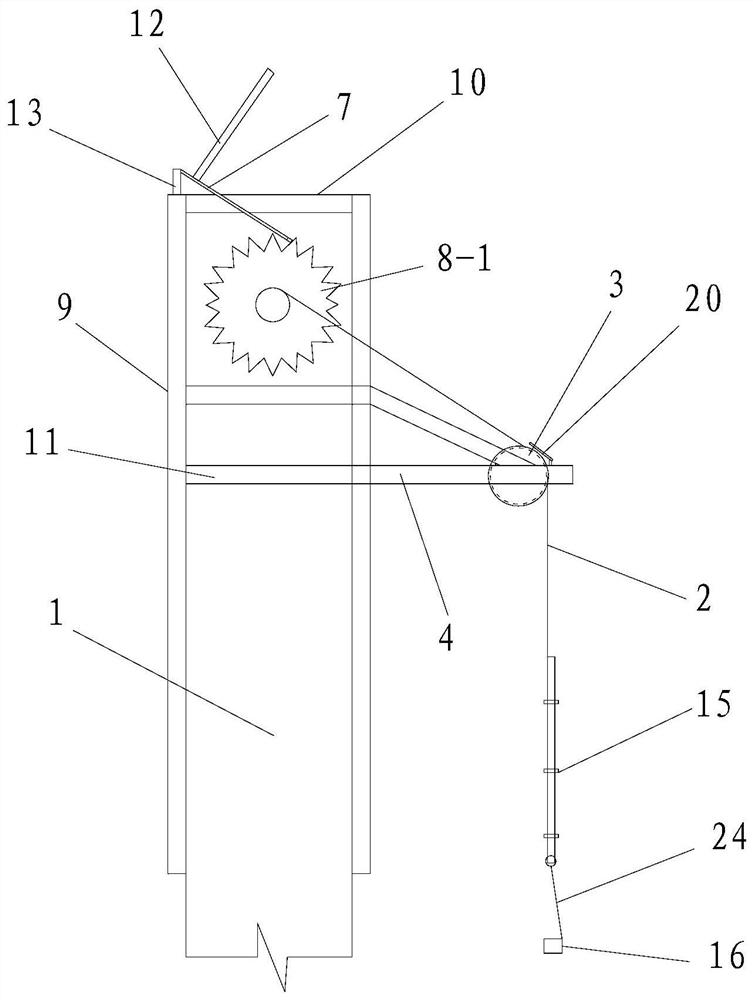

[0058] Such as figure 1 A safety belt hanging method for an underground diaphragm wall is shown, which adopts a safety belt hanging bracket arranged on the surrounding wall of the foundation pit under construction to hang the safety belt 16 worn by the construction personnel; The wall is arranged vertically and it is the enclosure wall of the foundation pit of the subway station. The enclosure wall of the foundation pit constructed includes an underground diaphragm wall 17 and a water retaining wall 1 arranged on the underground diaphragm wall 17. The underground diaphragm wall 17 The water retaining wall 1 and the retaining wall 1 are both vertically arranged reinforced concrete walls and the length of the two is the same. The water retaining wall 1 is arranged along the length direction of the underground continuous wall 17 and the two are arranged in parallel. The water retaining wall 1 is flush with the rear end of the underground diaphragm wall 17, see figure 2 ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com