Charging docking mechanism

A docking mechanism and articulation technology, applied in the field of robotics, can solve problems such as difficulty in determining the order, difficulty in ensuring accurate position of the end, inconvenient height adjustment, etc., to achieve the effect of increasing the scope of application, facilitating docking, and improving the probability of successful docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

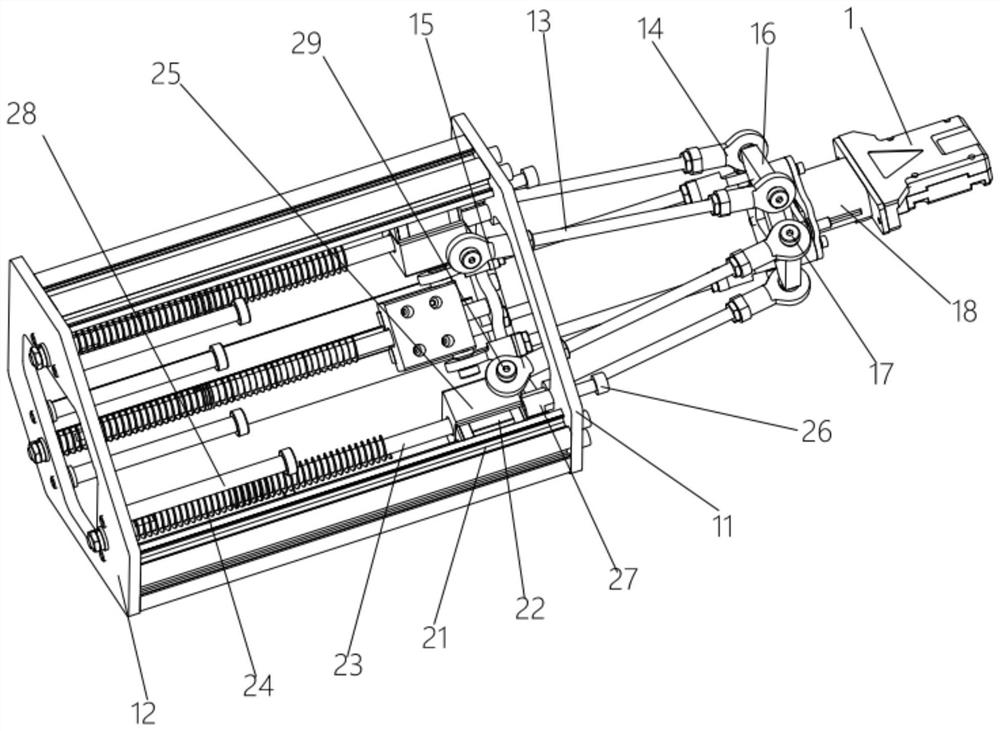

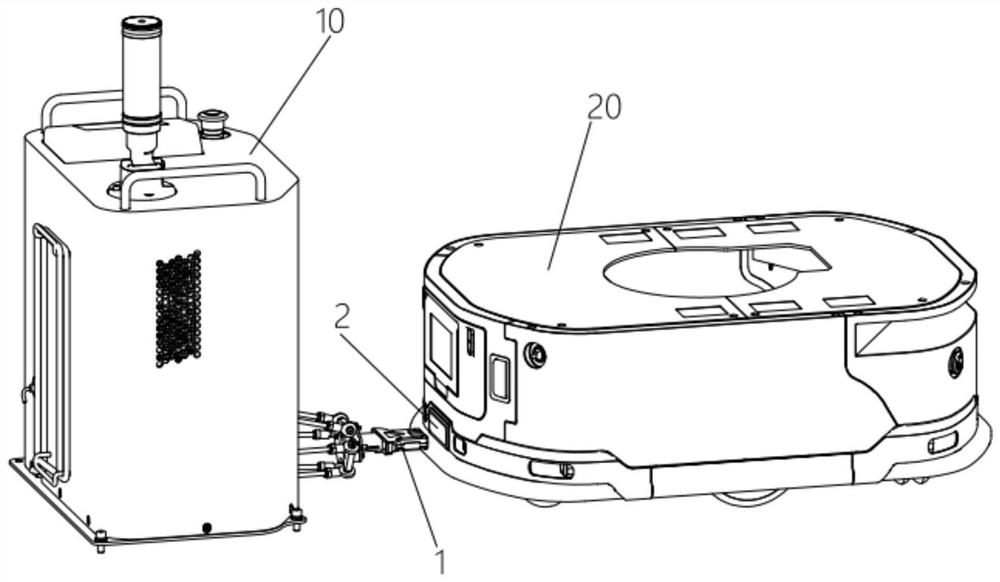

[0026] Such as Figure 1-2 As shown, the charging docking mechanism shown in this embodiment includes a base assembly, a male head 1 arranged in front of the base assembly, and a connecting rod assembly for connecting the base assembly and the male head 1. The base assembly includes front and rear parallel The front base plate 11 and the rear base plate 12 that are set are provided with three slides vertically arranged with the front base plate 11 and the rear base plate 12 at equidistant intervals between the front base plate 11 and the rear base plate 12. Rails 21, each slide rail 21 is provided with a slide block 22 matched with it, the slide block 22 can slide back and forth on the slide rail 21, and the connecting rod assembly includes three connecting rods with one end hinged on the slide block 22 The other end of the connecting rod group is hinged on the male head 1; in the above structure, the base assembly is installed on the charging pile 10, and the charging port 2 ...

Embodiment 2

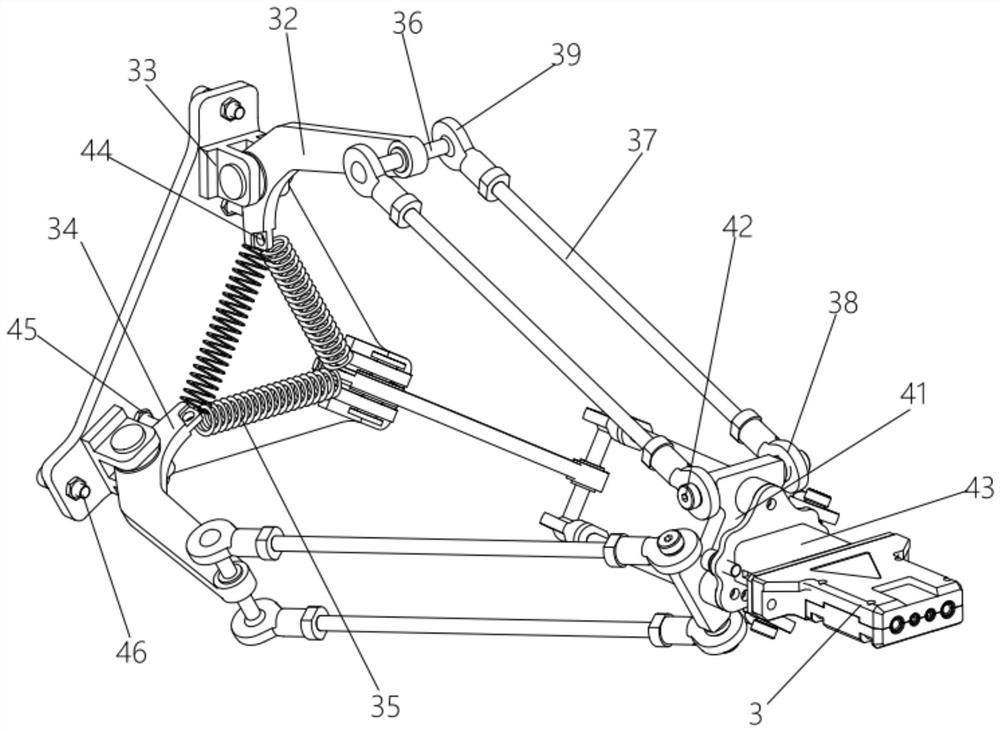

[0034] Such as Figure 3-4 As shown, the charging docking mechanism shown in this embodiment includes a base assembly, a male head 3 arranged in front of the base assembly, and a link assembly for connecting the base assembly and the male head 3. The base assembly includes a base The plate 31 is provided with three rotating arms 32 rotating on the base plate 31, and the connecting rod assembly includes three connecting rod groups, one end of which is hinged to the rotating arm 32, and the other end of the connecting rod group is hinged on the male head 3; In the above structure, the base plate 31 is installed on the charging pile 30, and the charging port 4 is provided on the robot 40. When the robot 40 needs to be charged, the robot 40 approaches the charging pile 30, and drives the charging port 4 to the male head 3. When the charging port 4 is aligned with the male head 3, the charging port 4 can be directly combined with the male head 3 to charge the robot 40. If the charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com