Pressure finger anti-escape structure of large-scale high-voltage synchronous motor and construction method of pressure finger anti-escape structure

A synchronous motor, high-voltage technology, applied in the field of electric motors, can solve problems such as rotor and pressure finger collision, damage to stator and rotor, de-soldering, etc., to avoid de-soldering accidents and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

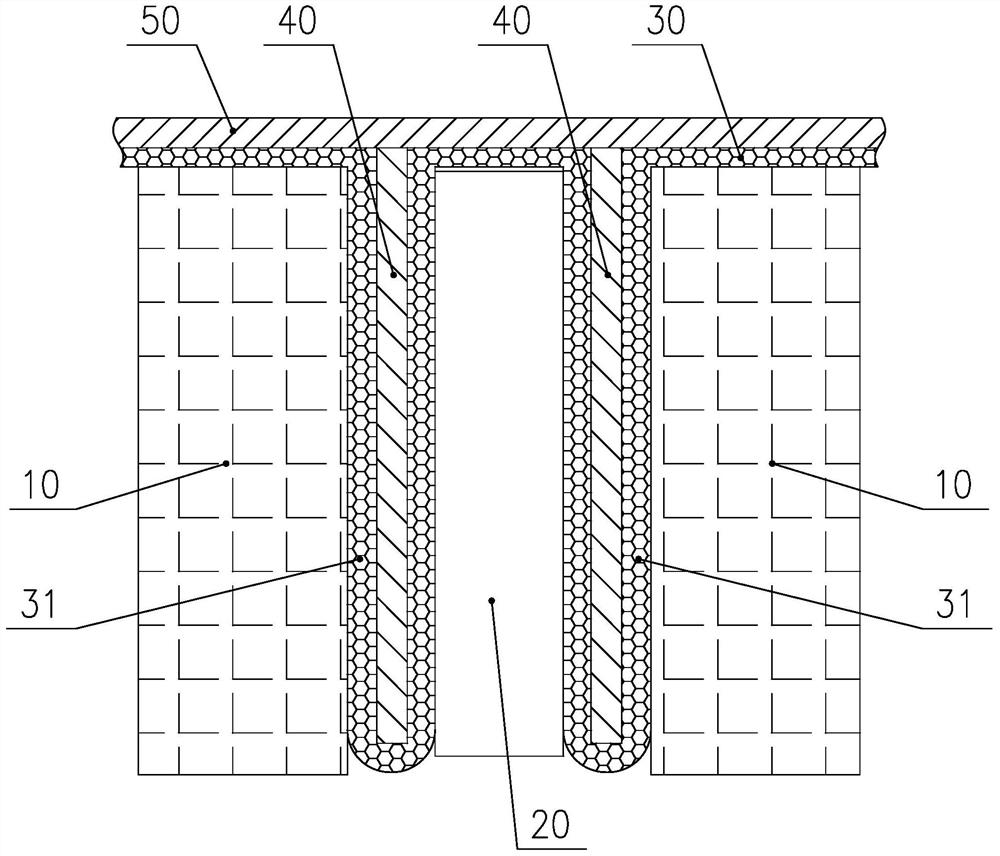

[0019] like figure 1 As shown in the figure, the pressure finger anti-spreading structure of a large-scale high-voltage synchronous motor includes a stator, and the stator includes a stator core, a stator winding, and tooth pressure plates arranged at both ends of the stator core; the stator winding includes a stator embedded in the stator core. The linear winding part in the winding slot and the end winding part located at both ends of the stator core and passing through the tooth pressure plate, the gap between any two adjacent winding units 10 of the end winding part is provided with a pressure Finger 20, one end of the pressure finger 20 is welded on the tooth pressure plate, and the other end is pressed on the end of the stator core; a ring of flexible Pad 30, the flexible pad 30 is provided with an embedding portion 31 embedded in the gap between the winding unit 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com