Electromagnetic orthopedic device and orthopedic method

An orthopedic and electromagnetic technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor flexibility, increased manufacturing costs, insufficient electromagnetic force, etc., to meet complex and accurate orthopedic requirements, reduce design and manufacturing costs, The effect of meeting the needs of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

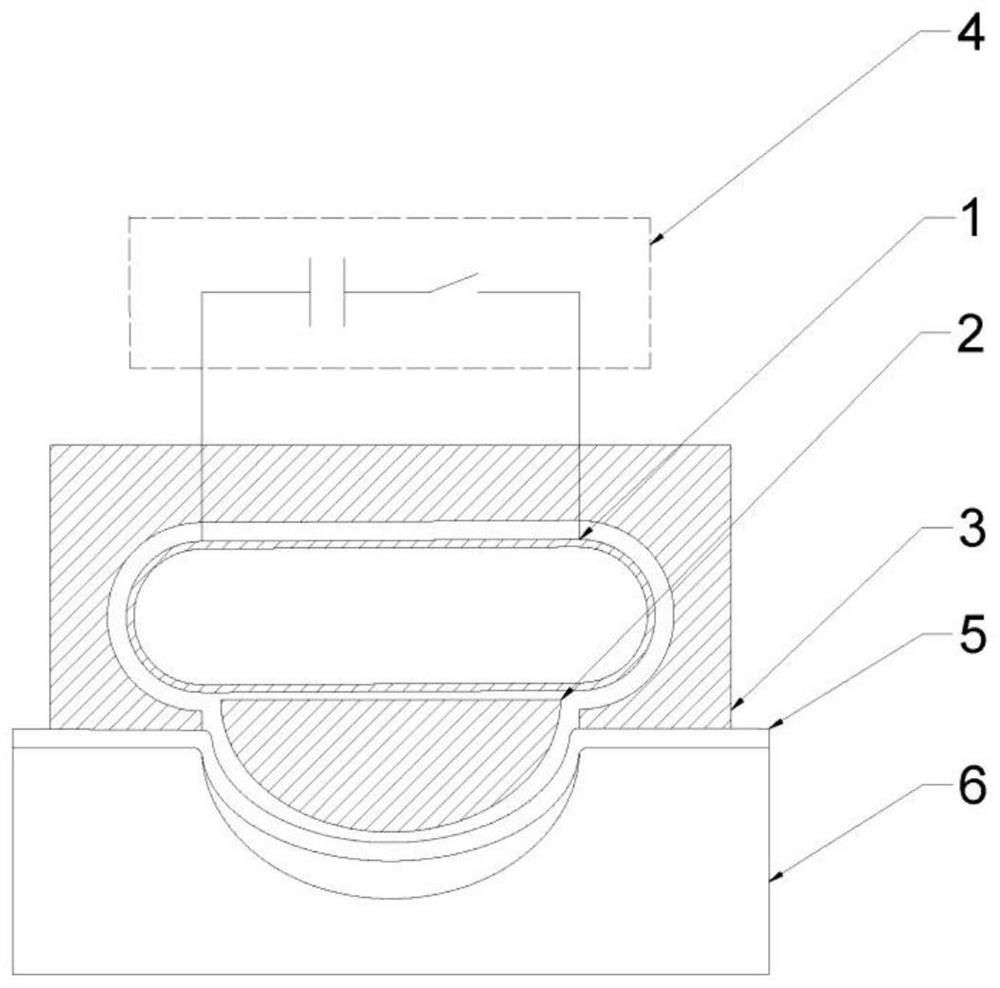

[0069] Such as Figure 4 As shown, one embodiment of the present invention provides an electromagnetic orthopedic device and an orthopedic method based on the device for orthopedromes with a workpiece for insufficient forming precision caused by the plate material. The electromagnetic orthopedic device includes: a constant pressure drive coil 1, a magnetic field shaping device 2, a conductive passage 3, a power source 4, a workpiece 5, and a mold 6. Among them, the uniform pressure drive coil 1 is a uniform pressure coil of the single layer of the copper wire, the wire cross-section size is 2 mm × 4 mm, a total of 18 turns; the outer surface profile of the magnetic field plaster 2 is the same as the contour of the mold, the material is copper, magnetic field shaping machine 2 Mechanically connected between the conductive channel 3 to constrain its position; the contour of the conductive passage 3 is the same as the outer surface profile of the uniform pressure drive coil 1, the mat...

Embodiment 2

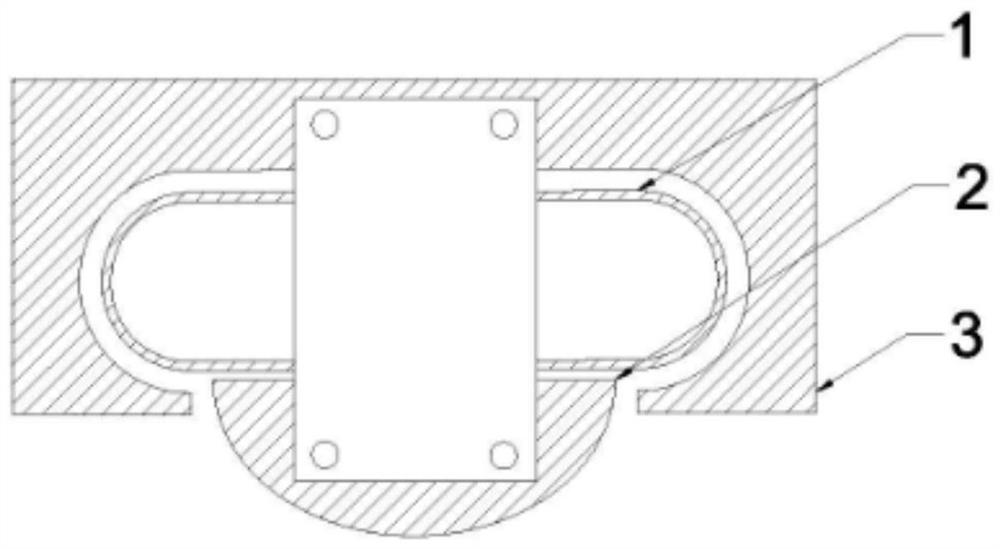

[0077] Such as Figure 5 As shown, one embodiment of the present invention provides an electromagnetic orthopedic device and an orthopedic method based on the device for multiple progressive forming of long straight plate members. The electromagnetic orthopedic device includes: a constant pressure drive coil 1, a magnetic field shaper 2, a conductive passage 3, a power supply 4, a workpiece 5, and a mold 6. Among them, the uniform pressure drive coil 1 is a uniform pressure coil of the single layer of the copper wire, the wire cross-section size is 2 mm × 4 mm, a total of 18 turns; the outer surface profile of the magnetic field plaster 2 is the same as the contour of the mold, the material is copper, magnetic field shaping machine 2 Mechanically connected between the conductive channel 3 to constrain its position; the contour of the conductive passage 3 is the same as the outer surface profile of the uniform pressure drive coil 1, the material is copper; the power supply 4 is a ca...

Embodiment 3

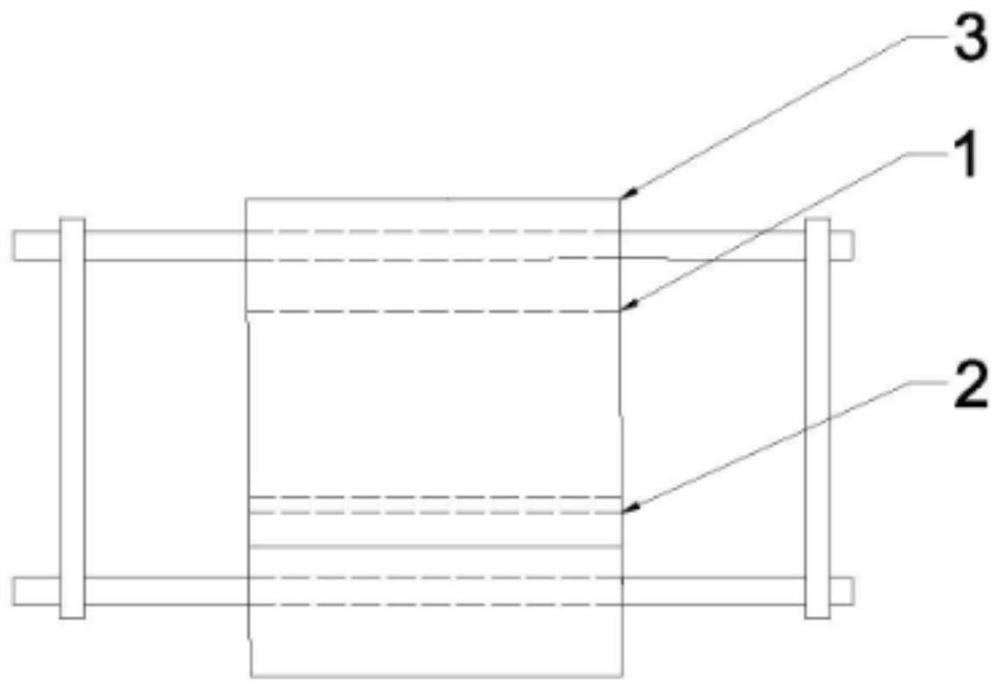

[0087] Such as Image 6As shown, one embodiment of the present invention provides an electromagnetic orthopedic device and an orthopedic method based on the device for local complex feature of the preformed workpiece. The electromagnetic orthopedic device includes: a constant pressure drive coil 1, a magnetic field shaper 2, a conductive passage 3, a power supply 4, a workpiece 5, and a mold 6. Among them, the uniform pressure drive coil 1 is a uniform pressure coil of the single layer of the copper wire, the wire cross section size is 2 mm × 4 mm, a total of 18 turns; the outer surface profile of the magnetic field plaster 2 is the same as the inner surface of the mold, the material is copper, magnetic field The planer 2 is mechanically connected to the conductive passage 3 to restrain its position; the contour of the conductive passage 3 is the same as the outer surface profile of the homogeneous pressure drive coil 1, the material is copper; the power supply 4 is a capacitive en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com