Universal drilling device for hexagonal locking screw holes of hexagonal nuts

A technology of hexagonal nuts and universal devices, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machines/drilling machines, etc., which can solve the problems of large quantity, low production efficiency, and large number of parts, and achieve reduction Production cost, convenient and fast clamping, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

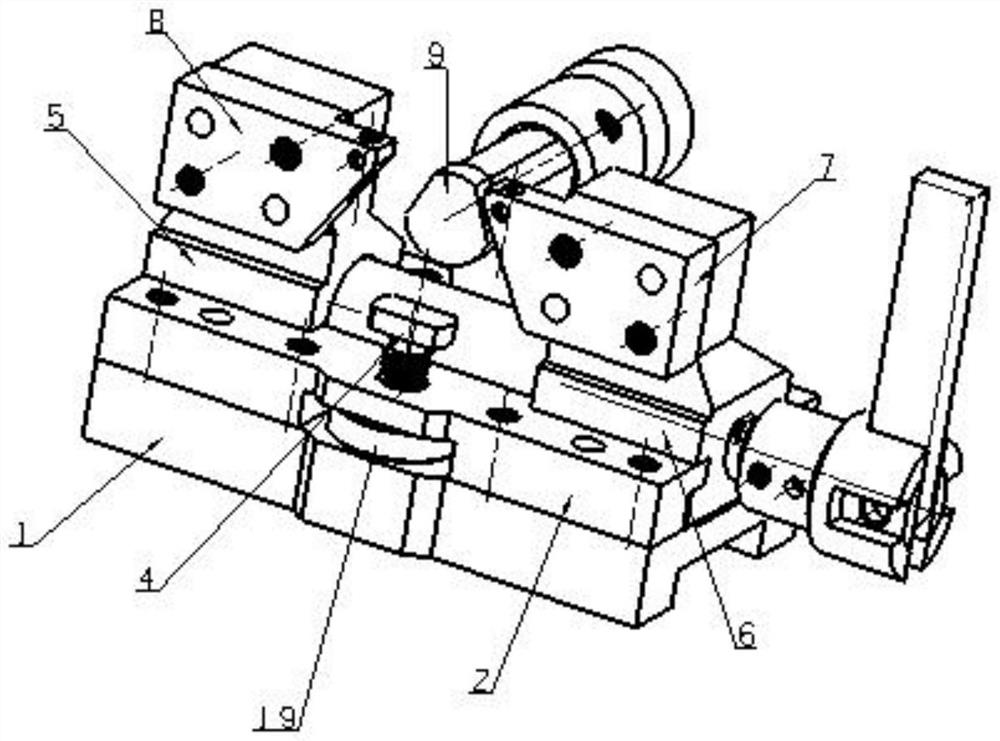

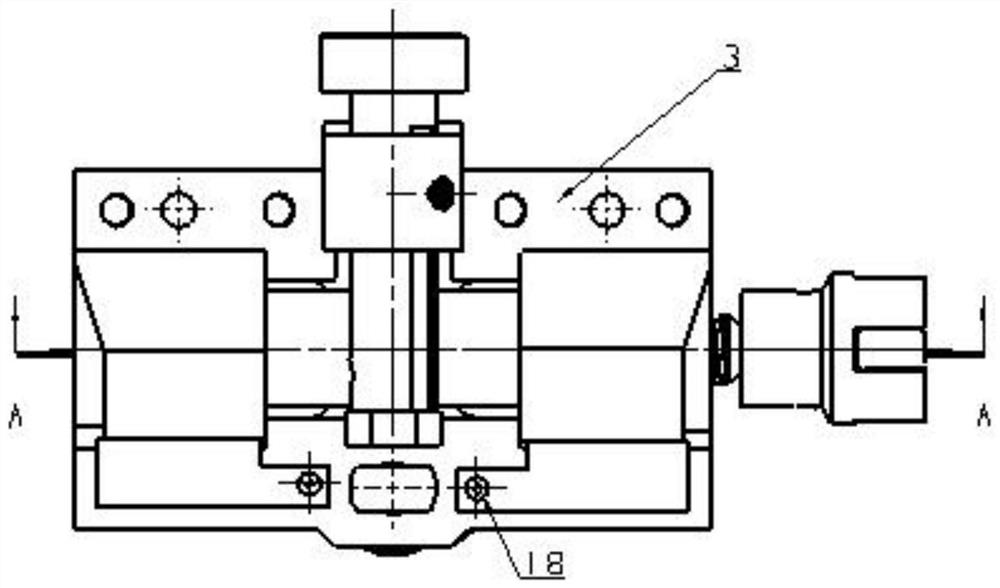

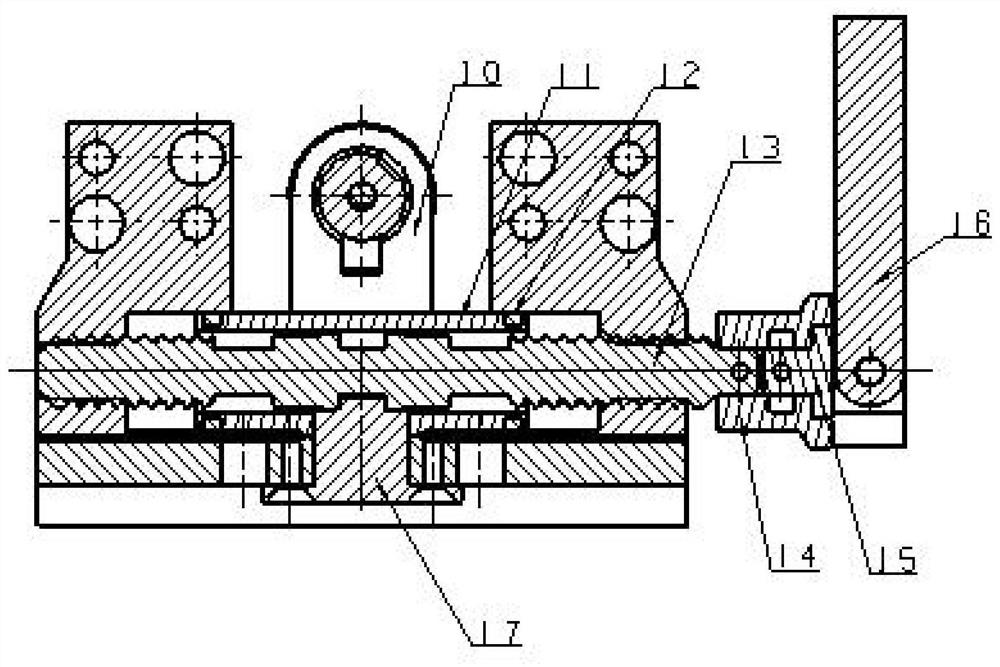

[0027] Such as Figure 1-3 As shown, a general device for drilling hexagonal nut hexagonal locking thread holes according to the present invention includes a base 1, a first guide rail 2, a second guide rail 3, a support screw 4, a first support slide 5, a second support slide Block 6, the first drilling template 7, the second drilling template 8, positioning rod 9, support seat 10, protective cover 11, screw rod 13, handle 16, positioning pin 17 and drill sleeve 18,

[0028] The positioning pin 17 is fixed on the base 1, and the first guide rail 2 and the second guide rail 3 are fixed on the base 1 through the positioning pin 17; 1, the first support slider 5 and the second support slider 6 are respectively loaded into the two ends of the screw rod 13, and the first support slider 5, the second support slider 6 and the screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com