Tool-pulling structure for horizontal lathe tiger head tool holder

A technology of tiger-head tool holder broaching and horizontal lathe, which is applied in the direction of tool holders, etc., can solve the problems of increasing the auxiliary time of machine tool processing preparation, re-calibrating the origin of the tool tip, and the long time of tool clamping and loosening, etc., to achieve The effect of improving market competitiveness, saving tool setting time, and shortening tool change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

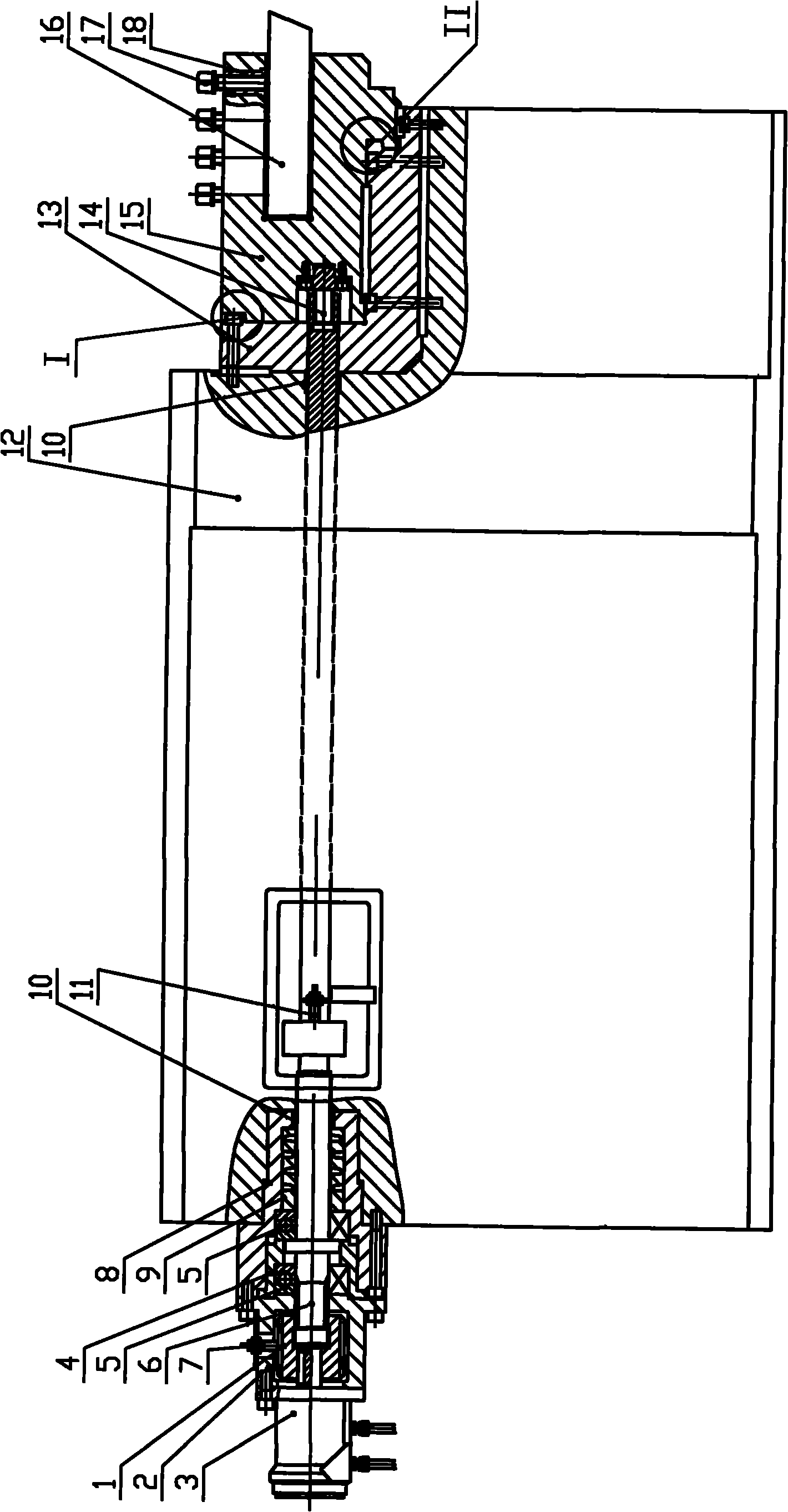

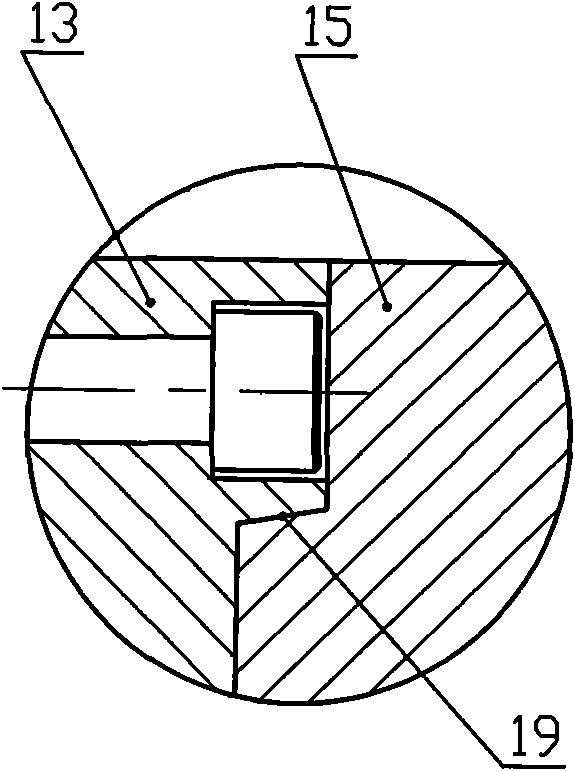

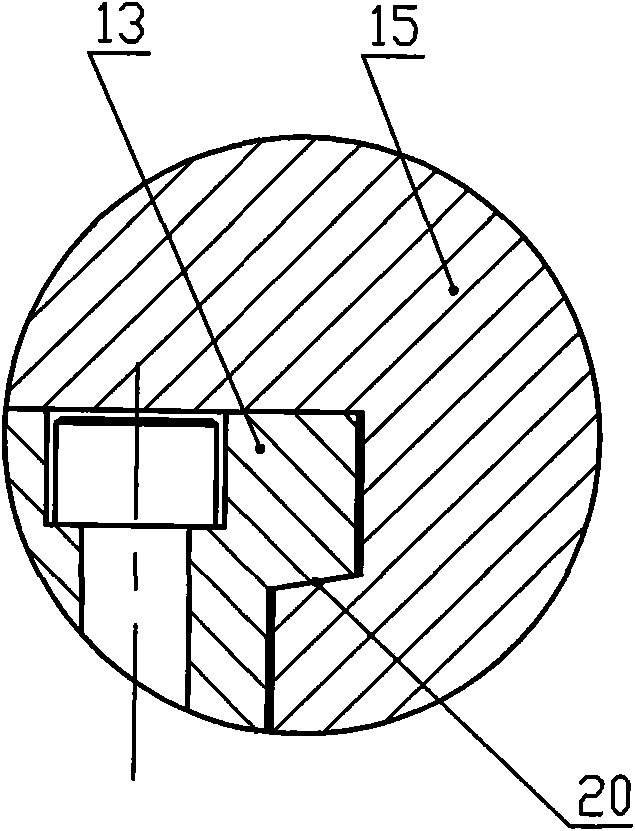

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] Depend on figure 1 to combine figure 2 , image 3 As shown, a horizontal lathe tiger head tool clip broaching device includes an L-shaped knife plate 12, a bearing seat 8 is embedded on the left side of the L-shaped knife plate 12, and the bearing seat 8 is fixed on the workbench 19 by screws. The interior of 8 is stepped, and there is a damping sleeve 9 inside the right side, which is set outside the lock knife pull rod 6 to play a role of vibration reduction and reduce the vibration and noise generated when the lock knife pull rod 6 rotates. The bearing seat 8 There is a flange cover 4 inside the left side, and a bearing 5 is respectively installed inside the bearing seat 8 and the flange cover 4, and the bearing 5 plays the role of supporting the lock knife pull bar 6. A locking limit switch 11 is installed on the right side of the bearing seat 8 and inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com