Dustproof material guiding device for film cutting machining

A material-guiding device and dust-proof technology, which is applied in the fields of removing smoke and dust, thin material handling, transportation and packaging, etc., can solve the problems that the cleanliness of the external air environment affects the product quality, and the stability of the conveying process is insufficient, so as to improve the cleanliness, It is flexible and convenient to use, and the effect of improving the stability of the guide material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

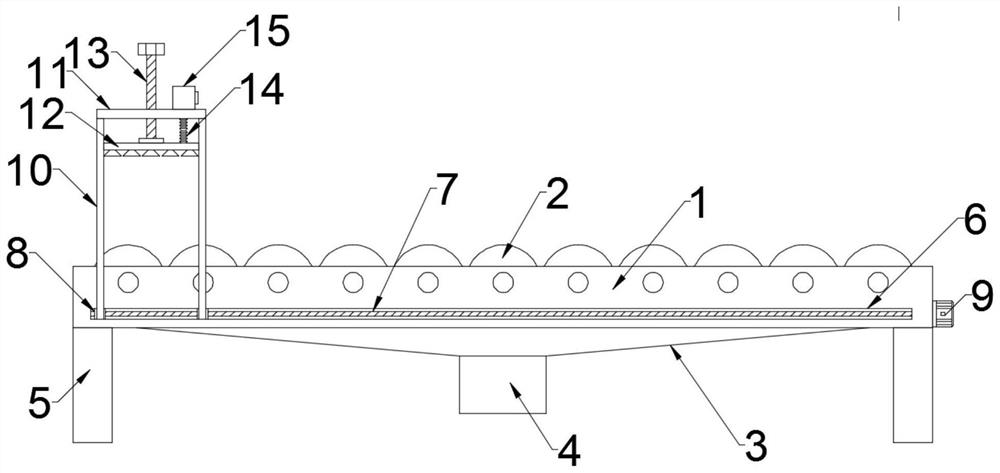

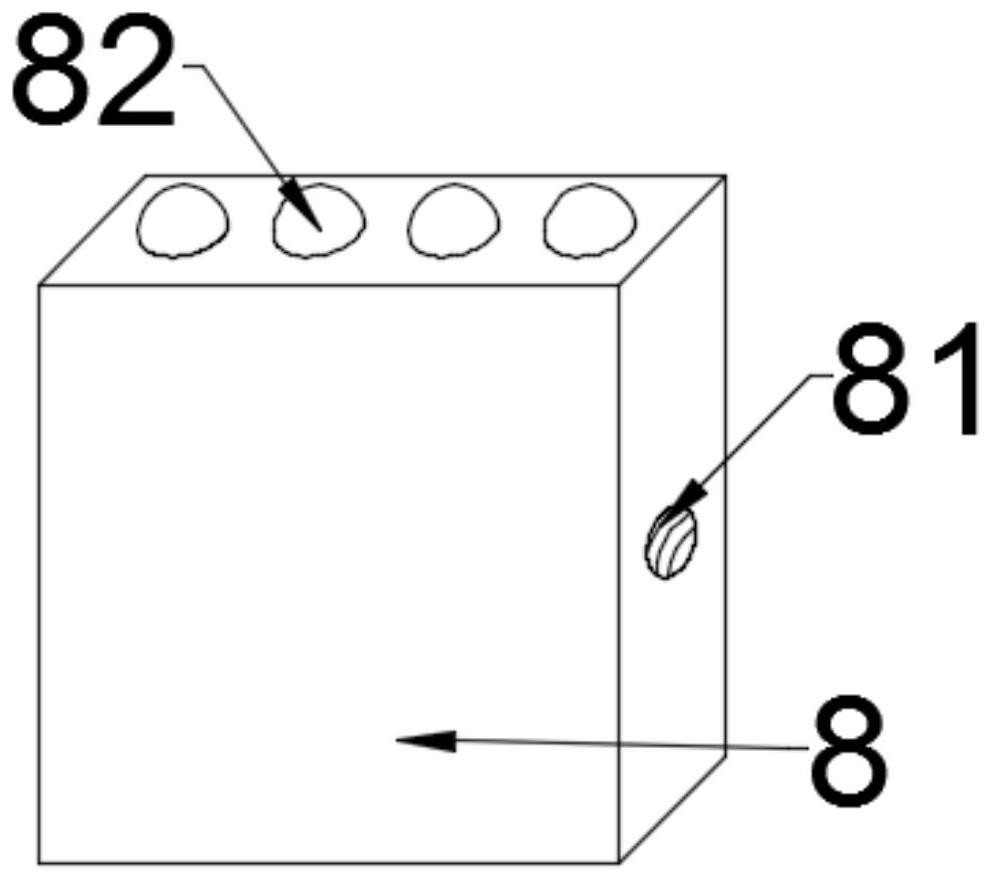

[0021] see Figure 1~2 , in an embodiment of the present invention, a dust-proof material guide device for film cutting, including a bracket 1, on which a plurality of sets of material guide rollers 2 are radially rotated, and the front and rear sides of the bracket 1 are symmetrically embedded A chute 6 is provided, and a guide screw 7 is rotatably connected in the chute 6, and a slider 8 is arranged on the periphery of the guide screw 7, and the corresponding slider 8 on both sides of the bracket 1 is connected and arranged. There is a mobile adsorption mechanism arranged opposite to the material guide roller 2, and the lower end of the support 1 is communicated with a dust removal chamber 4 through a dust collection cover 3.

[0022] Both sides of the lower end of the support 1 are symmetrically fixedly connected with outriggers 5, the support 1 has a "back" shape structure, and a servo motor 9 is installed on one side of the support 1, and the output end of the servo motor...

Embodiment 2

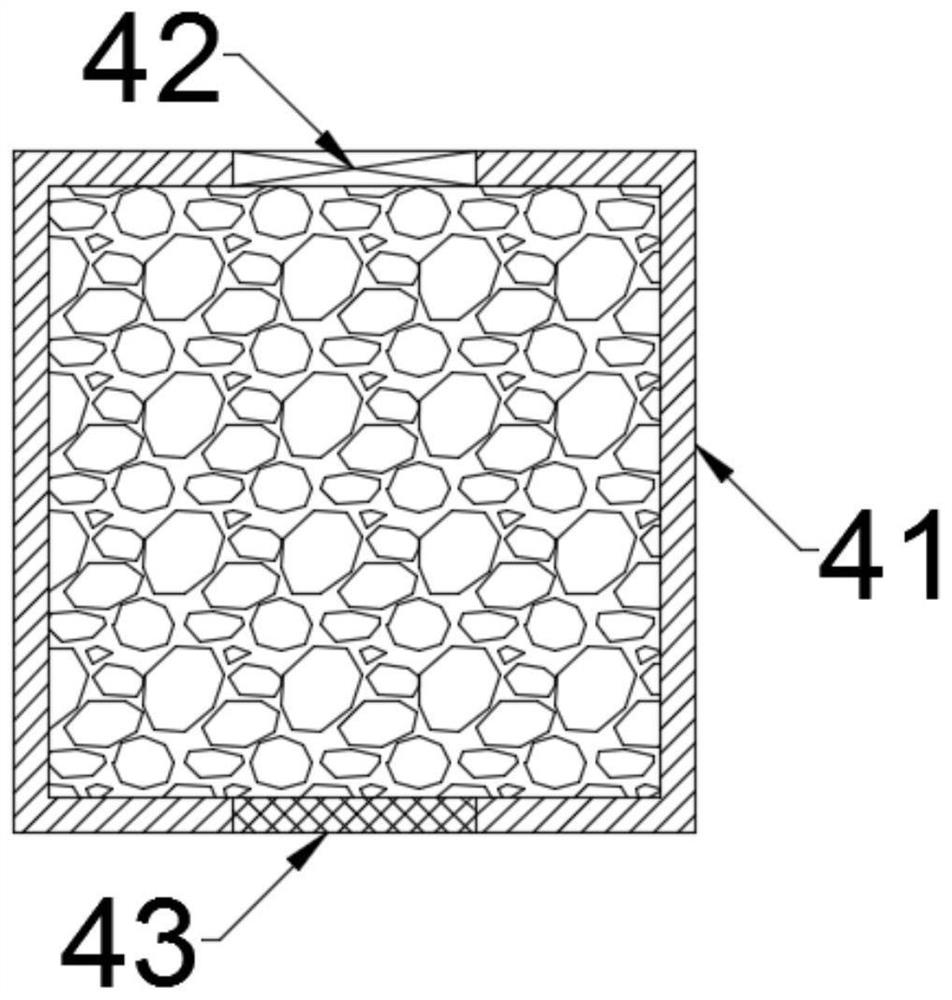

[0028] see image 3 , in the embodiment of the present invention, a dust-proof material guide device for film cutting processing, on the basis of embodiment 1, the dust collection cover 3 is a cover bucket structure, and the opening of the dust collection cover 3 is fixedly connected to the bracket 1 On the edge of the lower end, the dust collection cover 3 is connected with a dust removal chamber 4, and the dust removal chamber 4 is filled with activated carbon particles.

[0029] The dust removal chamber 4 includes a chamber shell 41, a fan 42 is inlaid at the connection between the upper end of the chamber shell 41 and the dust collecting cover 3, and the output direction of the fan 42 is from the outside of the chamber shell 41 to the inside of the chamber shell 41, and the chamber An air outlet 43 is provided through the lower end of the shell 41 , and a metal mesh covered with filter cloth is embedded in the air outlet 43 . After the fan 42 is started, the airflow is bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com