A kind of heat-conducting and wave-absorbing integrated graphene thermal interface material and preparation method thereof

A technology of thermal interface material and graphene, applied in heat exchange materials, chemical instruments and methods, chemical industry, etc., can solve the problems of size limitation, complicated process, unsuitable for large-scale production, etc., and achieve the increase of dosage, High absorption, oil absorption value reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

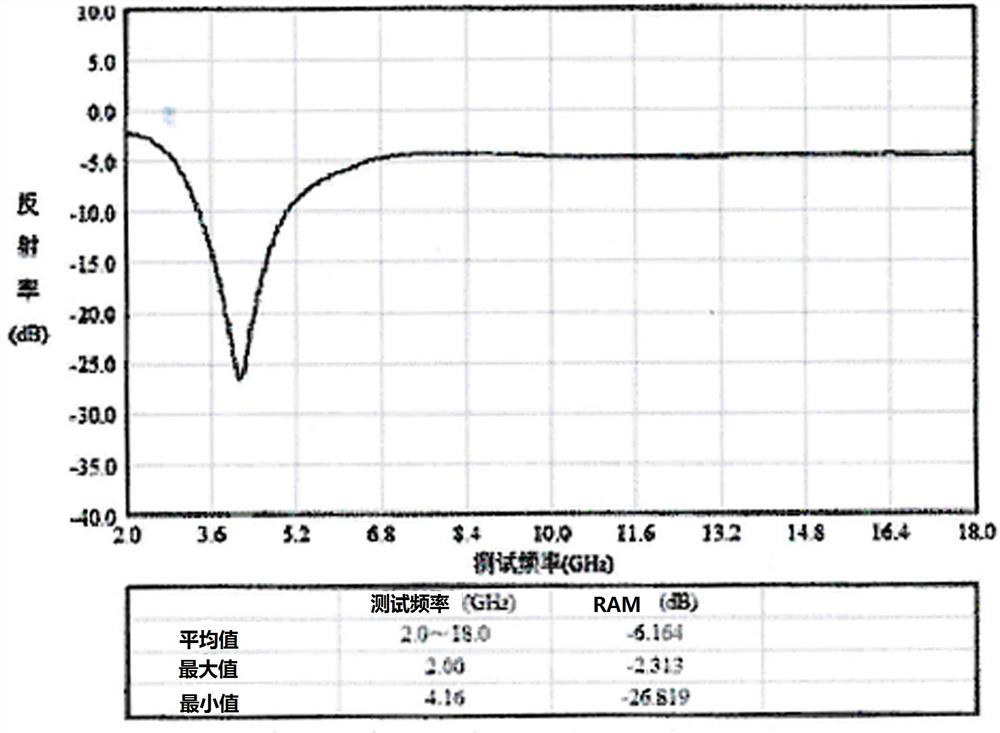

Image

Examples

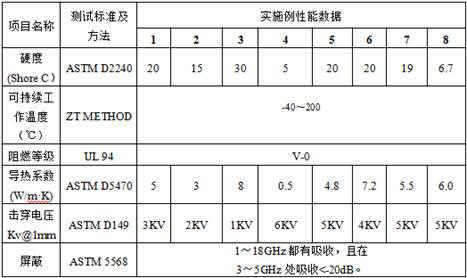

Embodiment 1

[0039] This embodiment provides a graphene thermal interface material integrated with heat conduction and wave absorption.

[0040] The preparation steps are as follows:

[0041] S1. In parts by weight, use 100 parts of Al with a particle size D50 of 2um 2 O 3 Add it to the high-speed mixer, add 1 part of KH-550 to 50 parts of anhydrous ethanol and mix it, then add it to the high-speed mixer, then add 0.01 part of concentrated hydrochloric acid, stir for 30min, and finally add 1 part under ultrasonic (100MHz) A single-layer graphene oxide powder with a sheet diameter of 20-30um is prepared, stirred for 30 minutes, and dried to obtain a graphene-thermally conductive and insulating composite material.

[0042] S2. In parts by weight, add 100 parts of carbonyl iron powder, a conventional magnetic insulating material with a particle size of D50 of 3um, into a high-speed agitator, add 0.1 part of KH-550 to 50 parts of anhydrous ethanol, and add high-speed after mixing. Then add ...

Embodiment 2

[0047] This embodiment provides a graphene thermal interface material integrated with heat conduction and wave absorption.

[0048] The preparation steps are as follows:

[0049] S1. In parts by weight, add 100 parts of silicon nitride with a particle size D50 of 100 nm to a high-speed agitator, add 0.1 part of KH-550 to 10 parts of anhydrous ethanol and add it to a high-speed agitator after mixing, then Then add 0.01 part of concentrated hydrochloric acid, stir for 10min, and finally add 1 part of single-layer graphene oxide with a sheet diameter of 10-20um under ultrasonic (200MHz), stir for 10min, and dry to obtain graphene-thermally conductive insulating composite material.

[0050] S2. In parts by weight, add 100 parts of conventional magnetic insulating material carbonyl nickel powder with a particle size of D50 of 100nm into a high-speed stirrer, add 0.1 part of KH-550 to 10 parts of absolute ethanol and mix and add high-speed Then add 0.01 part of concentrated hydroch...

Embodiment 3

[0055] This embodiment provides a graphene thermal interface material integrated with heat conduction and wave absorption.

[0056] The preparation steps are as follows:

[0057] S1. In parts by weight, add 100 parts of silica with a particle size D50 of 10um to a high-speed agitator, add 5 parts of KH-550 to 50 parts of anhydrous ethanol and add it to a high-speed agitator after mixing, then Then add 1 part of concentrated hydrochloric acid, stir for 30min, and finally add 10 parts of double-layer graphene oxide with a sheet diameter of 90-100um under ultrasonic (500MHz), stir for 30min, and dry to obtain graphene-thermally conductive insulating composite material.

[0058] S2. In parts by weight, add 100 parts of conventional magnetic insulating material ferrite with a particle size D50 of 8um to the high-speed stirrer, add 5 parts of KH-550 to 50 parts of anhydrous ethanol and mix and then add high-speed stirring Then add 1 part of concentrated hydrochloric acid, stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com