Adjustable coke oven chute opening structure

A chute opening and adjustable technology, which is applied in the field of coke ovens, can solve the problems that the bridge bricks cannot be replaced and adjusted, and achieve the effects of improving temperature and maturity differences, saving energy, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

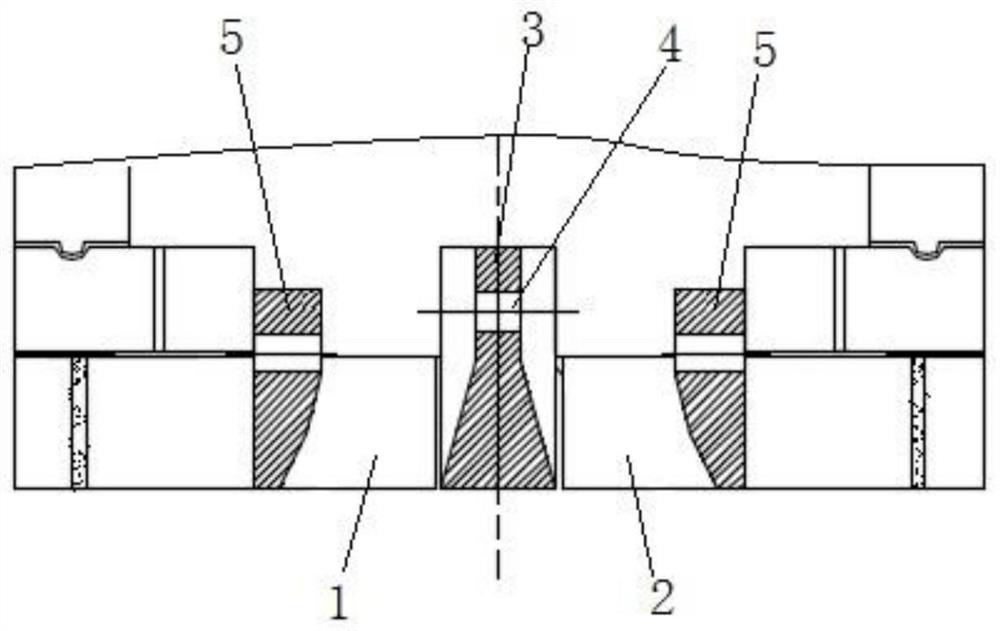

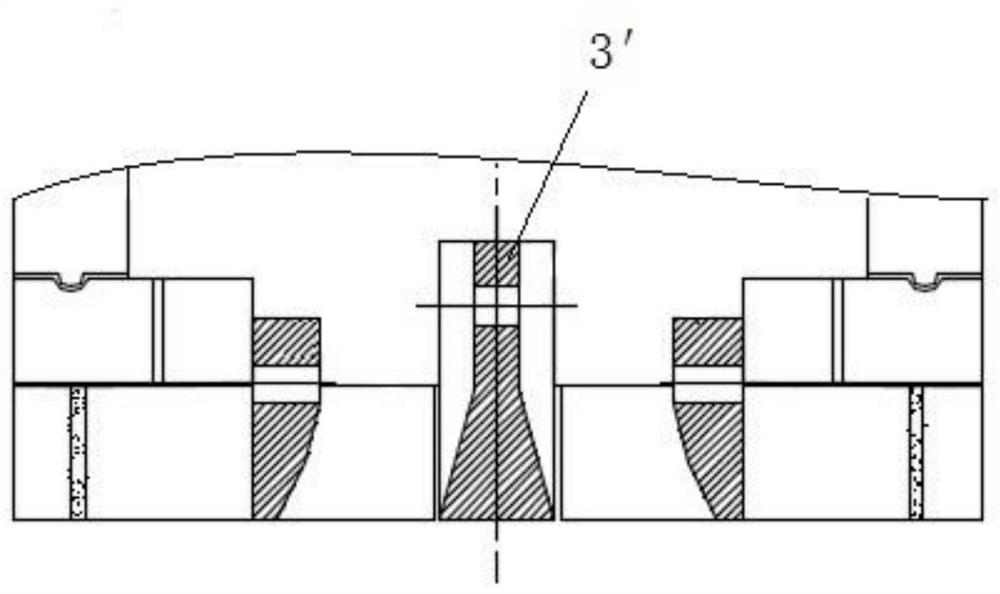

[0021] Such as figure 1 , figure 2 As shown, an adjustable coke oven chute opening structure according to the present invention includes a chute 1 and a chute 2 arranged side by side corresponding to the same vertical fire passage, and a chute 1 and a chute 2 are arranged between the chute 1 and chute 2 There are nose bridge bricks 3; the nose bridge bricks 3 are movably placed on the top of the masonry in the chute area, and can be replaced; the nose bridge bricks 3 are provided with various specifications according to different heights.

[0022] The distance between the top surface of the nose bridge brick 3 and the bottom surface of the vertical fireway is -200-350mm.

[0023] The upper part of the nose bridge brick 3 is a cuboid structure, and the two sides of the lower part are arc-shaped surfaces extending outward and downward respectivel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap