Grid damping support

A grid and damping technology, which is applied to bridge parts, bridge materials, bridges, etc., can solve the problems of frictional pendulum bearings that are difficult to control, have no anti-pullout function, and produce vertical displacement, etc., and achieve strong energy consumption , low manufacturing and maintenance costs, and stable energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

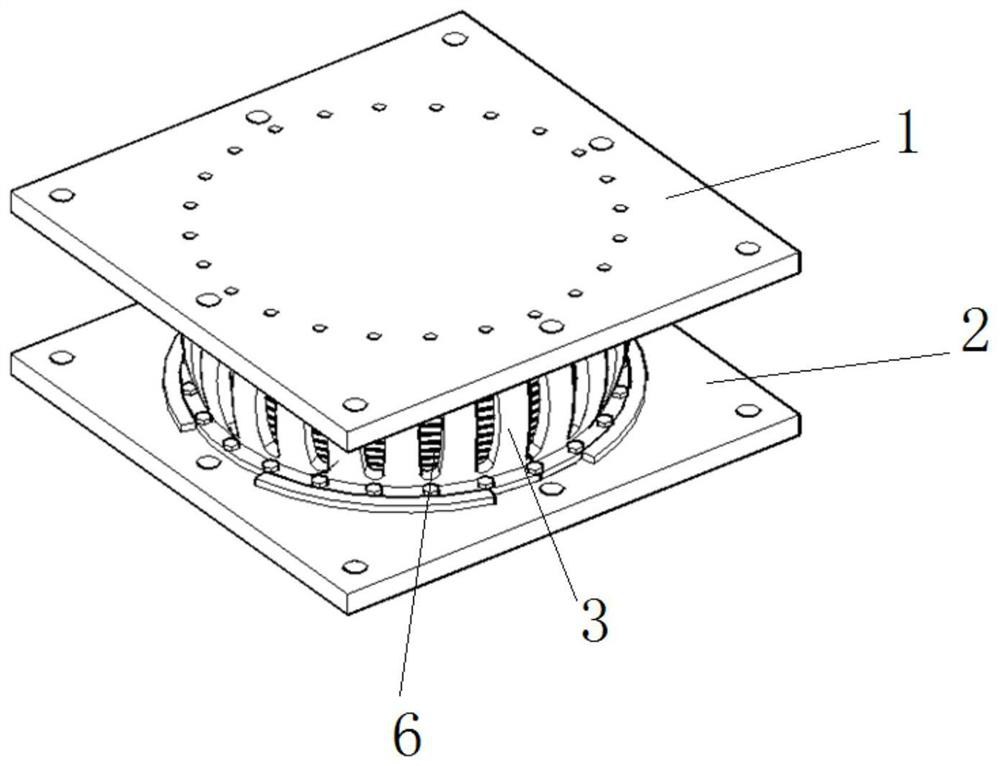

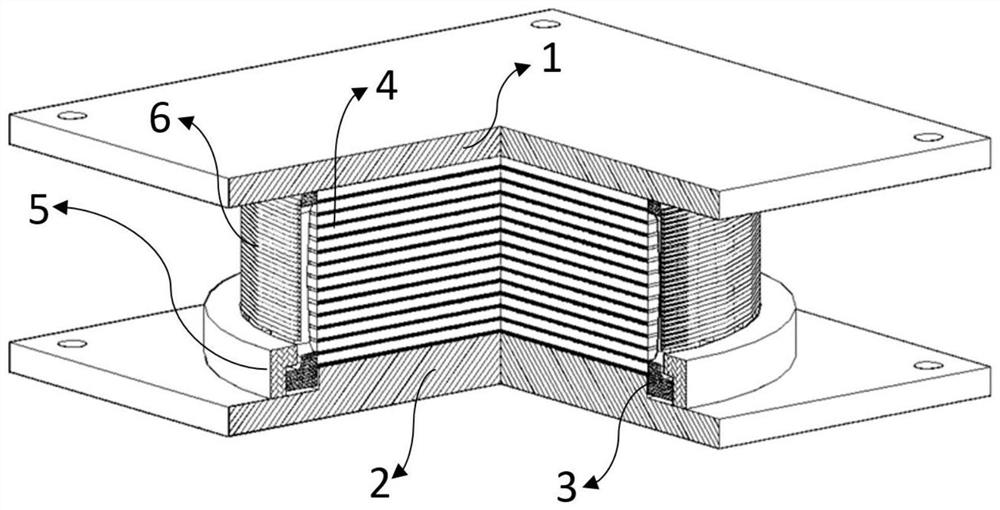

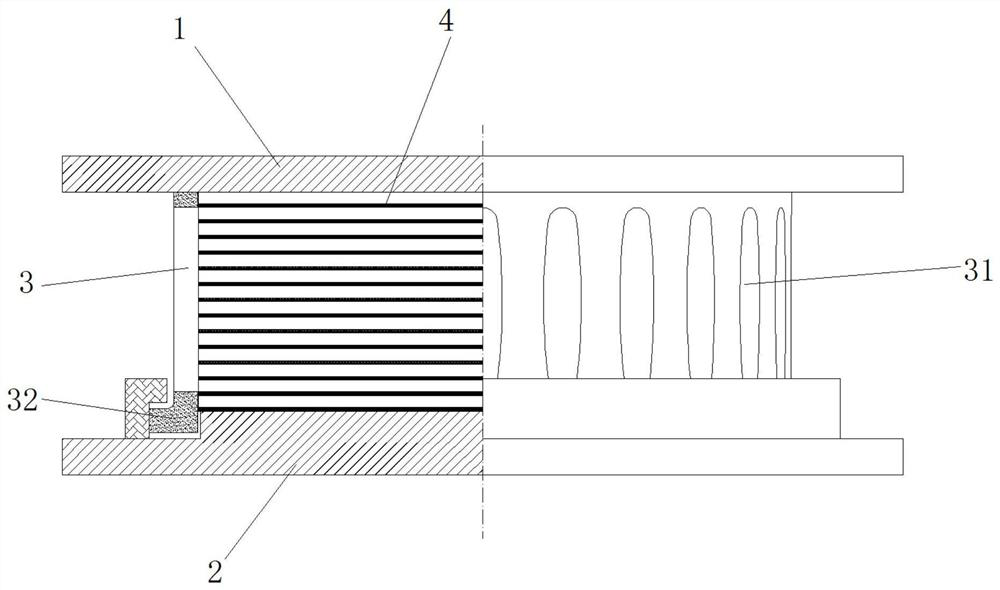

[0031] Such as Figure 1~3 The grid damping support shown includes a grid damper 3, an elastic support body 4, a top plate 1 and a bottom plate 2; the grid damper 3 is a hollow shell with openings at both ends, and the shell is made of steel made, such as image 3 As shown; a plurality of weakened holes 31 are provided on the housing; the elastic support body 4 is embedded in the housing of the grid damper 3; the lower port of the housing is arranged on the bottom plate 2 and is fixed with the bottom plate Connected, the lower end surface of the elastic support body 4 is in contact with the upper surface of the bottom plate 2;

[0032] Preferably, the weakened holes 31 are round holes, oval holes, polygonal holes or vertically arranged shuttle-shaped holes; the weakened holes 31 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com