High-temperature triaxial rheological and dynamic and static combined loading test device for coal and rock mass

A combination of dynamic and static loading and triaxial rheological technology, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as the inability to measure radial deformation in water, and achieve the elimination of horizontal force, Accurate detection results and high voltage stabilization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

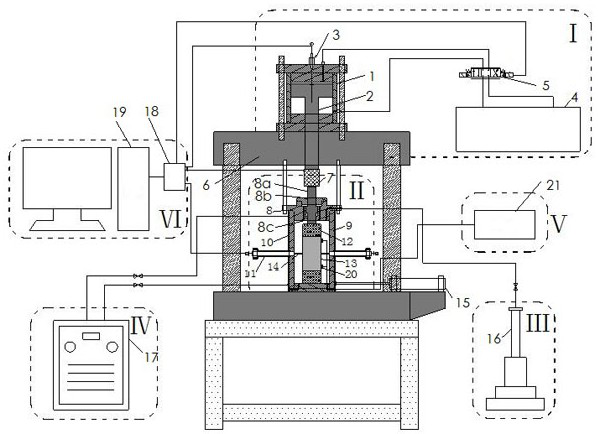

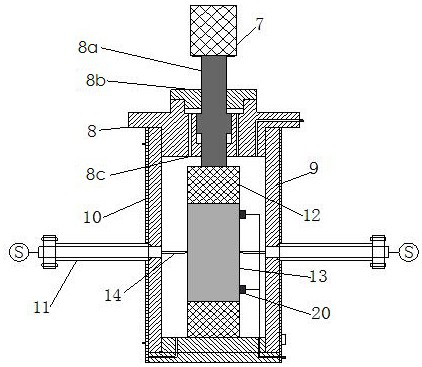

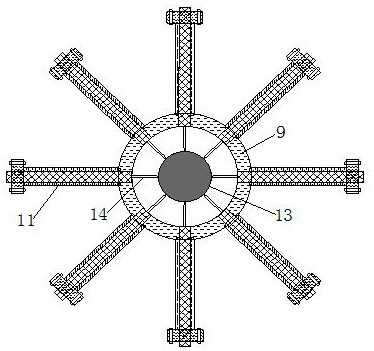

[0035] Such as figure 1As shown, it is a high-temperature triaxial rheological and dynamic-static combined loading test device for coal and rock mass, including axial loading system I, three-axis main test system II, confining pressure tracking system III, temperature control system IV, and acoustic emission monitoring system Ⅴ. Data acquisition and control system Ⅵ; Axial loading system Ⅰ is the loading cylinder 1 and its servo oil source system 4 arranged above the press 6, the top of the loading cylinder 1 is provided with an axial displacement sensor 3, the axial displacement sensor 3 Connected to the controller 18; the loading cylinder 1 is connected to the axial force sensor 7 and the electro-hydraulic servo valve 5, and the electro-hydraulic servo valve 5 is connected to the servo oil source system 4 and the controller 18, and the controller 18 controls after receiving the feedback signal from each sensor Axial loading rate and amplitude, using constant displacement, co...

Embodiment 2

[0049] In the following, through Example 2 and with reference to the accompanying drawings, the technical goals and implementation methods that can be achieved by the high-temperature triaxial rheological and dynamic-static combined loading test device for coal and rock mass will be introduced in detail. The operation process of mutual cooperation between each system is introduced as follows:

[0050] Here, taking the cylindrical coal sample of the standard sample Ф50×100mm as an example, the test device of the present invention is used to study the rheological properties of the coal sample under the conditions of THMC coupling and combined dynamic and static loading.

[0051] In conjunction with accompanying drawing, its specific implementation steps are as follows:

[0052] Step 1, Sampling: Drill a cylindrical coal sample of Ф50×100mm along the vertical direction of coal seam bedding on the large coal sample, and the sample size error shall not be higher than 1.0mm; and gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com