Concrete strength testing device and using method thereof

A technology for concrete strength and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, and testing material hardness, etc., and can solve the problems of single adjustable angle posture and limited functions of the rebound hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

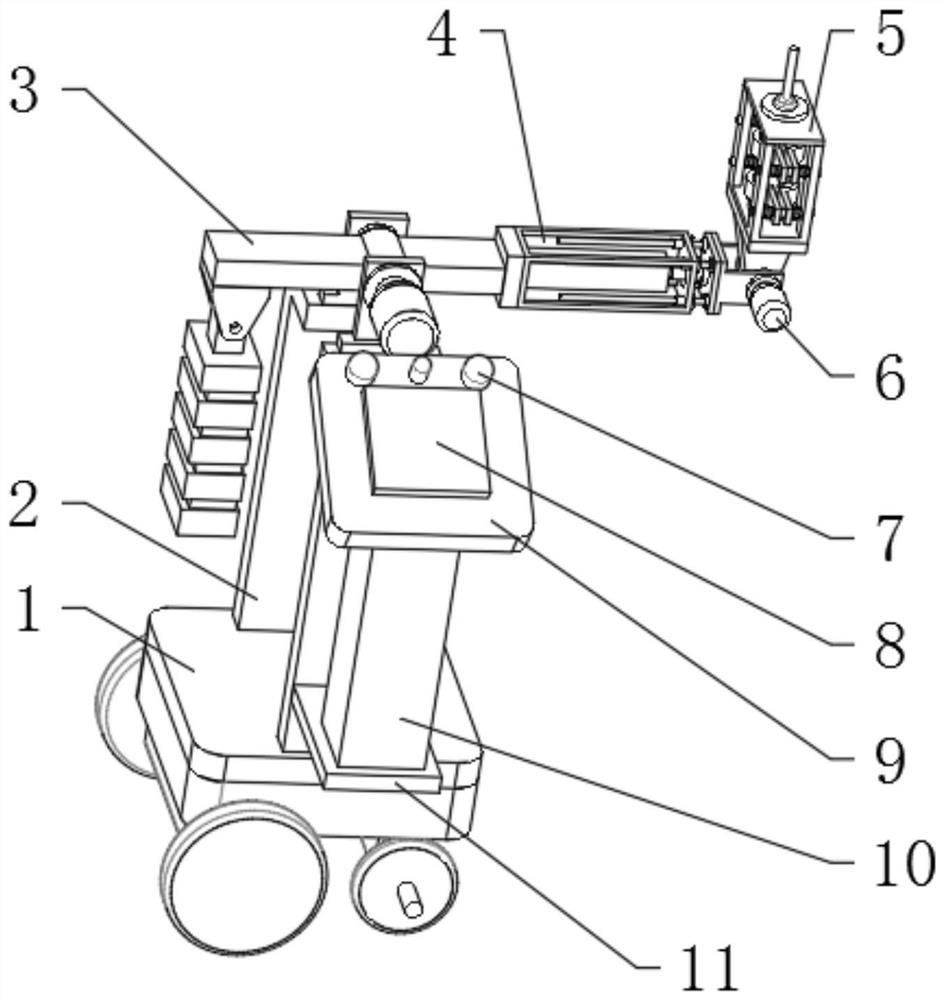

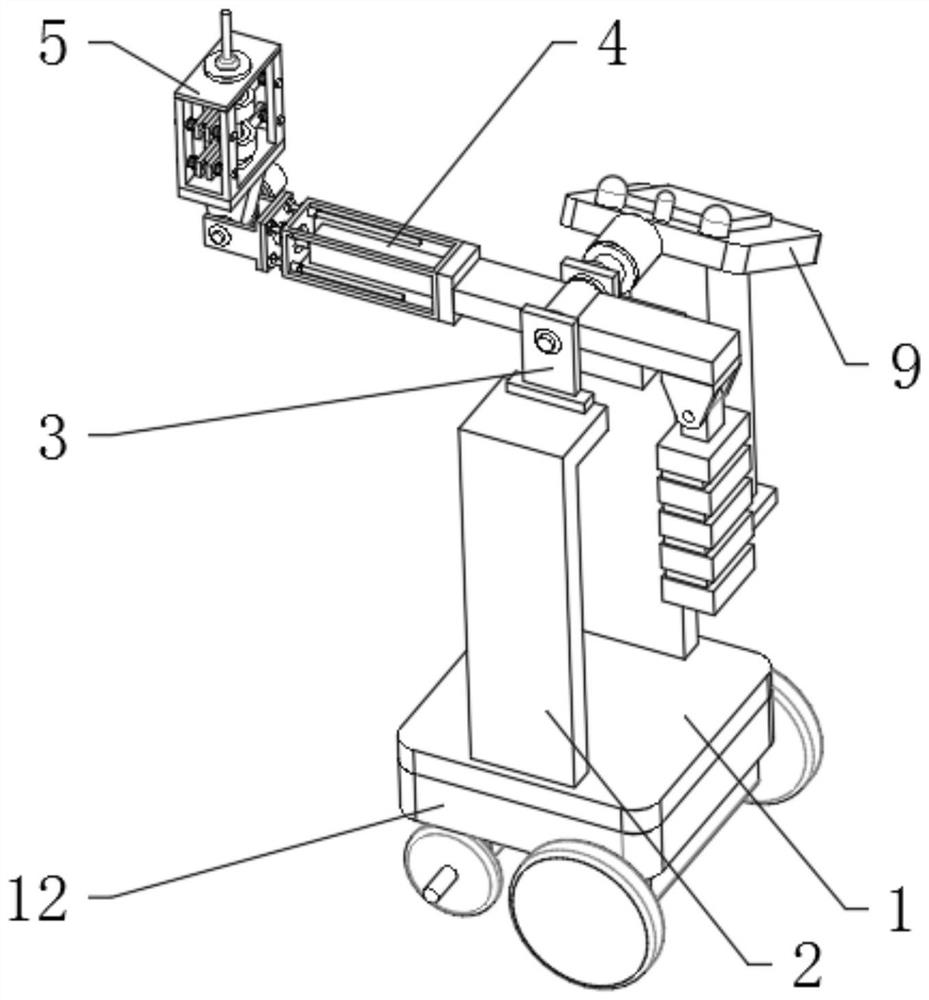

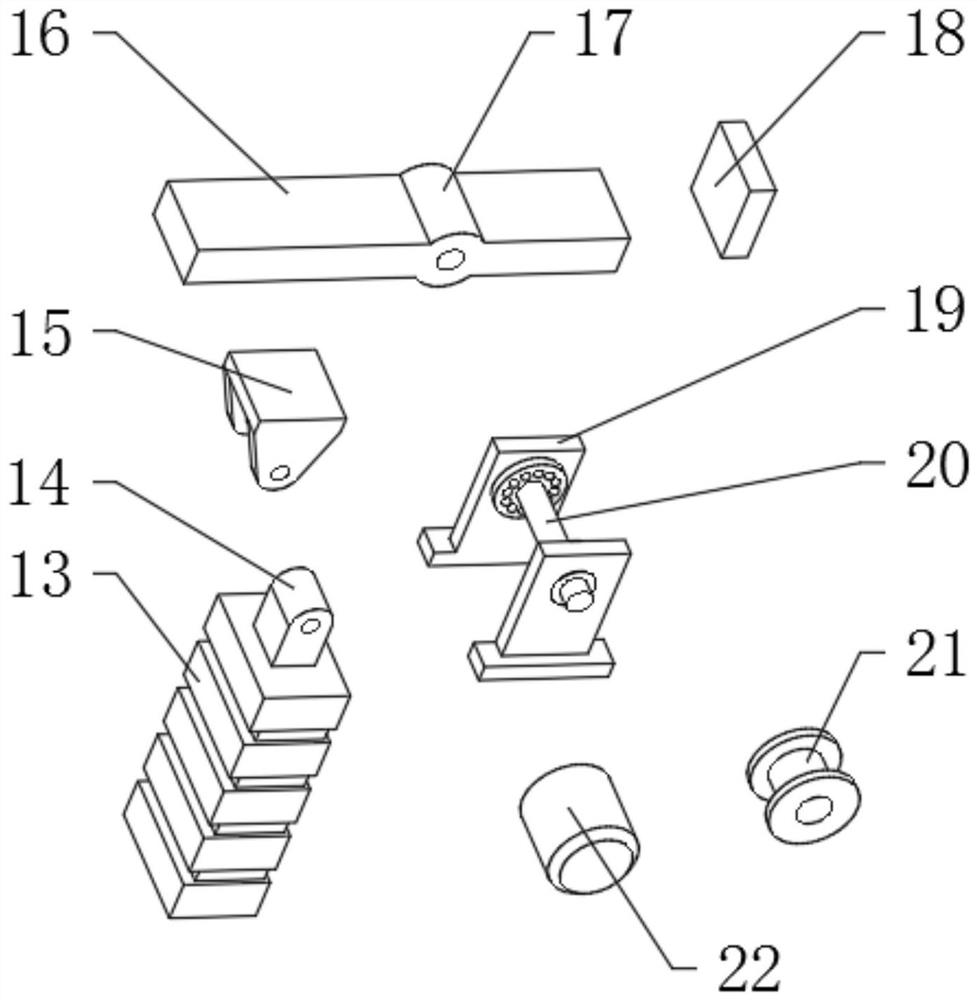

[0041] A concrete strength testing device, such as Figure 1-7 As shown, it includes a bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with a stand 2, the number of stand 2 is two, the top outer wall of the stand 2 is fixedly connected with a main adjustment assembly 3, and the outer wall of one side of the main adjustment assembly 3 is fixed. Connected with a telescopic assembly 4, the outer wall of one side of the telescopic assembly 4 is fixedly connected with an auxiliary adjustment assembly 6, and the outer wall of one side of the auxiliary adjustment assembly 6 is fixedly connected with a placement assembly 5, and the interior of the placement assembly 5 is provided with a rebound instrument 34; the main adjustment assembly 3 includes a beam 16 and a bracket 19, the bottom outer wall of the bracket 19 is fixedly connected to the top outer wall of the stand 2, the inner wall of the beam 16 is provided with a middle cylinder 17, and the inner w...

Embodiment 2

[0048] A method for using a concrete strength testing device, such as Figure 1-7 As shown, the test device described in this embodiment is the test device in embodiment 1, and its method of use includes the following steps;

[0049] S1: install the rebound hammer 34; directly stretch the splint 40 through the rebound hammer 34, and fix the rebound hammer 34 by the splint 40, and the plug sleeve 32 can provide further fixation;

[0050] S2: driving device; through external command remote control, the body 12 drives the device into the measurement area;

[0051] S3: Wall measurement; the main adjustment component 3 is leveled, and the rebound instrument 34 is used for measurement. When the position needs to be changed, the main adjustment component 3 and the auxiliary adjustment component 6 realize the angle adjustment, and keep the placement component 5 always in the horizontal direction;

[0052] S4: Ceiling measurement; the main adjustment component 3 is vertical, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com