Wire threading machine

A wire threading and wire machine technology, applied in the field of wire threading machines, can solve the problems that steel strands cannot be reused, affect the turnover speed of templates, increase the use of steel strands, etc., achieve reduction of manual labor load, low manufacturing cost, The effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

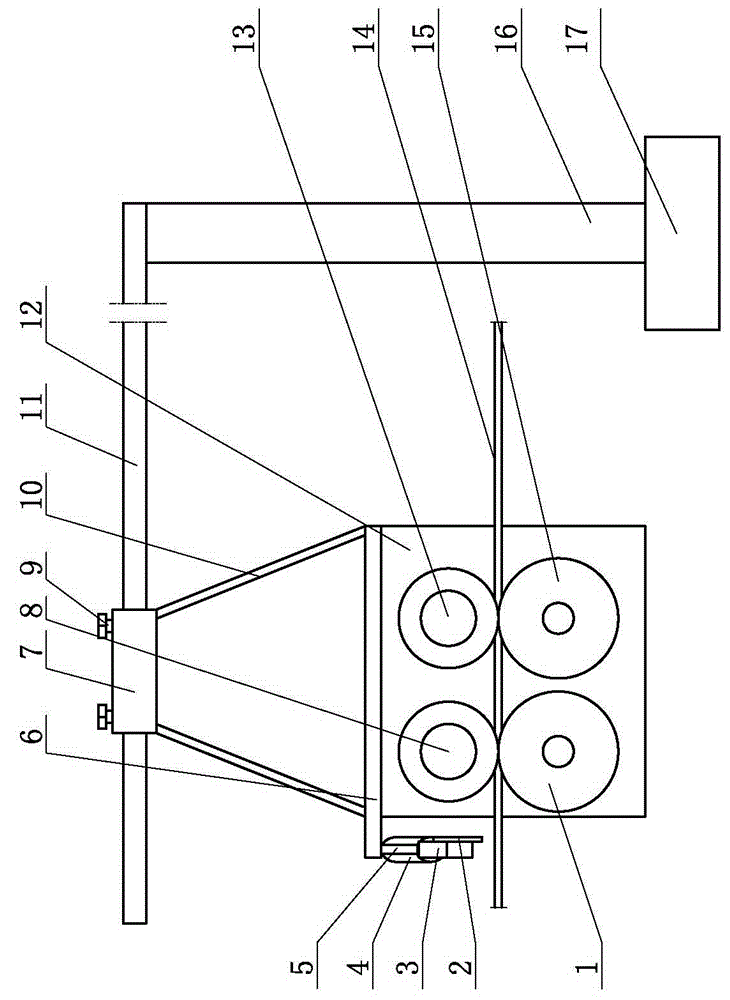

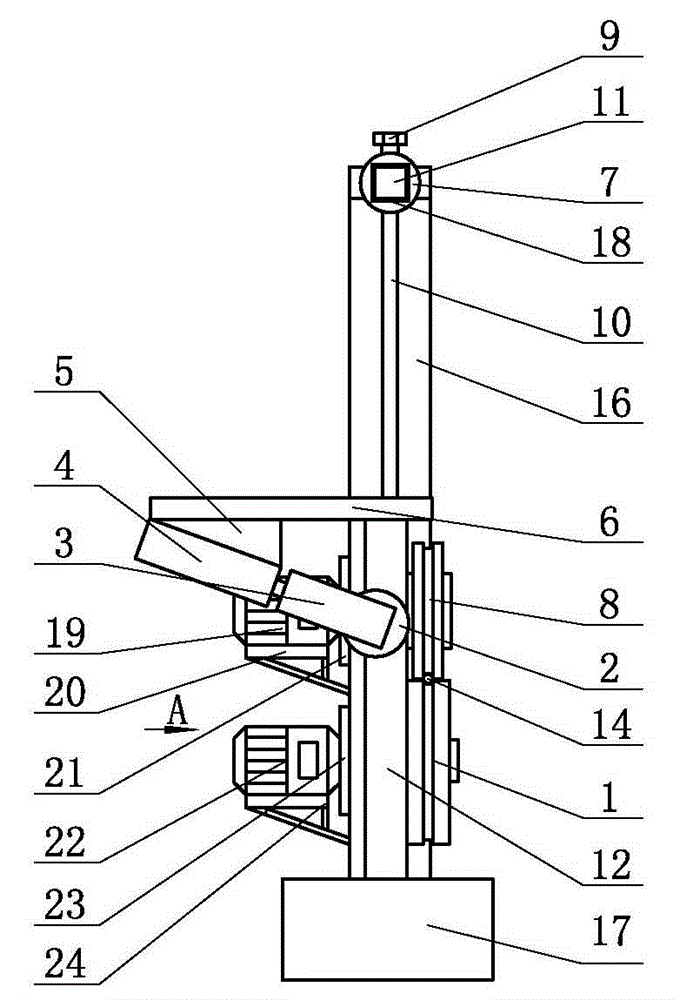

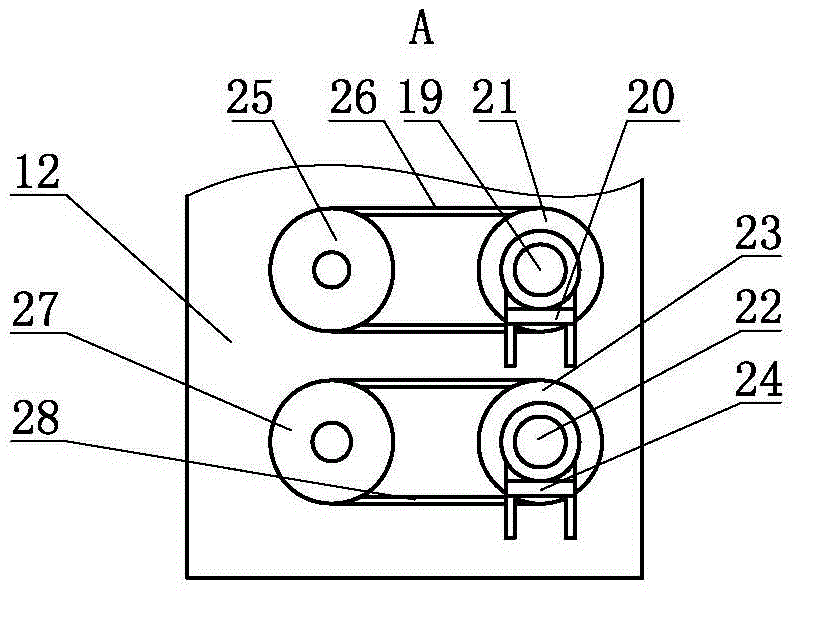

[0009] threading machine, such as figure 1 and figure 2 As shown, it includes a base 17, a vertical bar 16 is installed on the base 17, a horizontal shaft 11 is installed on the top of the vertical bar 16, a fixed seat 6 is hoisted on the horizontal shaft 11, a fixed plate 12 is installed on the bottom of the fixed seat 6, and a driving wheel is installed on the fixed plate 12 8 and lower driving wheel 1, steel strand 14 is set between upper driving wheel 8 and lower driving wheel 1, and steel strand 14 is all tangent to upper driving wheel 8 and lower driving wheel 1, and the axle of upper driving wheel 8 is connected Motor 19, the wheel shaft of lower driving wheel 1 connects lower motor 22, upper motor fixing mount 20 and lower motor fixing mount 24 are set on the fixed plate 12, upper motor 19 and lower motor 22 are respectively installed in upper motor fixing mount 20 and lower motor fixing On the frame 24, the cylinder 4 is installed on the fixed seat 6, the cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com