Design method of electric vehicle battery simulation system for off-board charger field detection

An on-site detection, electric vehicle technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of long test process, inability to adjust state of charge and voltage independently, limited test range and test items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The invention will be further described in detail below in conjunction with the drawings.

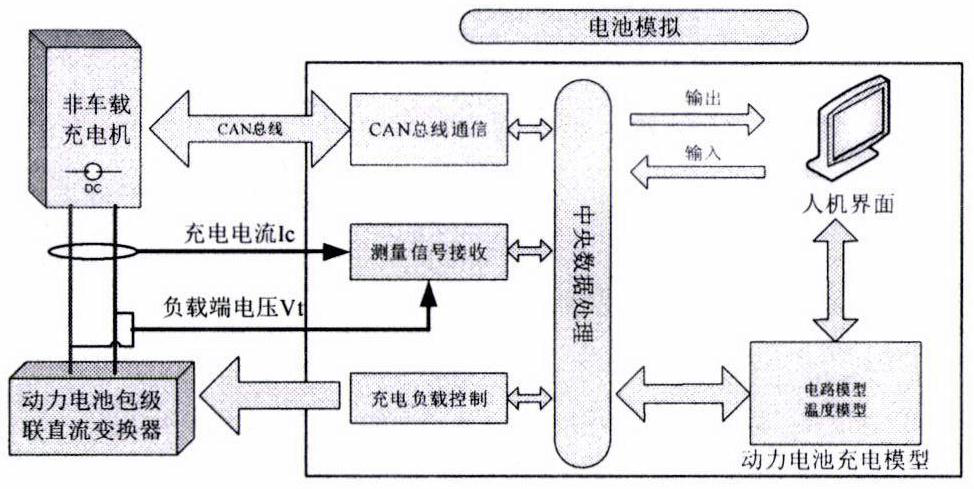

[0021]The functional structure design of the lightweight analog battery system is as followsfigure 1 As shown, the central control unit constructs a power battery charging model and simulates the actual battery charging response according to the set battery parameters and the measured charging current or voltage. The model includes battery voltage, current, SOC (State Of Charge), temperature and other information . When it is necessary to detect the response of the charger when the battery is abnormally charged, the power battery model can simulate battery overvoltage, overtemperature and other abnormal charging phenomena; the charging load control module sets the power battery pack cascade DC according to the calculation results of the battery model The parameters of the converter simulate the charging response of the actual battery; the man-machine interface module displays the charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com