Anti-electric shock outdoor socket and plug structure

An anti-electric shock and outdoor technology, applied in the direction of preventing contact with live contacts, devices, circuits, contact parts, etc., can solve problems such as hidden dangers, short-circuit risk, wire shaking, etc., achieve good elasticity and wear resistance, and improve anti-corrosion Electric shock effect, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

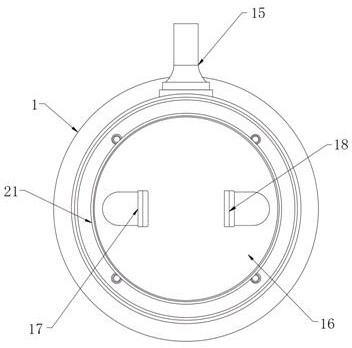

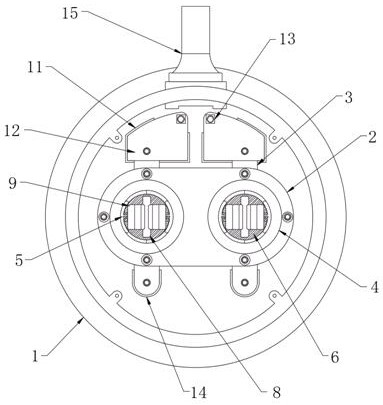

[0031]Embodiment 1, an electric shock-proof outdoor socket structure, including a socket body 1, a first wire inlet seat 15 and a top cover 16, characterized in that: the side outer wall of the socket body 1 is connected to the first wire inlet seat 15 , the first wire inlet seat 15 is connected to the inside of the socket body 1, and the top of the socket body 1 is connected to the top cover 16. The device as a whole is a split connection mode, and the whole has high disassembly and assembly convenience, which is convenient. To clean or overhaul the inside of the device, the material of the first wire inlet seat 15 is rubber material, which is convenient for wrapping the cables connected to the inside of the socket body 1, and improves the overall practicability;

[0032] The inner bottom of the socket body 1 is provided with a fixed module 2, and the fixed module 2 is provided with a first copper bar 3, and the first copper bar 3 runs through both sides of the fixed module 2,...

Embodiment 2

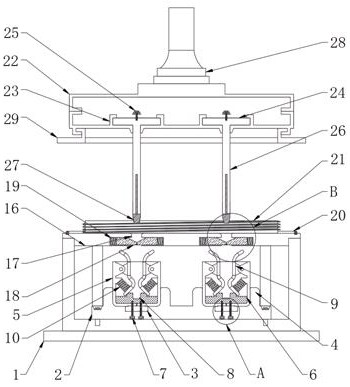

[0038] Embodiment 2, an electric shock-proof outdoor plug structure, including a plug body 22 and a connecting plate 29, is characterized in that: the plug body 22 includes a third limiting groove 23 and a second incoming wire seat 28, and the third limiting The slots 23 are arranged symmetrically with respect to the central axis of the plug body 22. There are two inner bottoms of the plug body 22, and each third limiting slot 23 is provided with a third copper bar 24. The third copper bar The bottoms of 24 are provided with pins 26, and the tops of the third copper bars 24 are provided with second terminal blocks 25, the pins 26 all pass through the bottom of the plug body 22, and the bottoms of the pins 26 are provided with insulating heads 27, Simultaneously, the spacing between the two pins 26 is equal to the spacing between the two slots 17, and the two-inlet socket 28 is arranged on the top of the plug body 22, and the two-inlet socket 28 communicates with the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com