Method for pre-embedding sensing line in channel cover plate

A sensing line and cover plate technology, which is applied in the field of pre-embedded sensing lines in the trench cover plate, can solve the problems of being easily damaged and not easy to detect the damage of the trench cover plate in time, and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

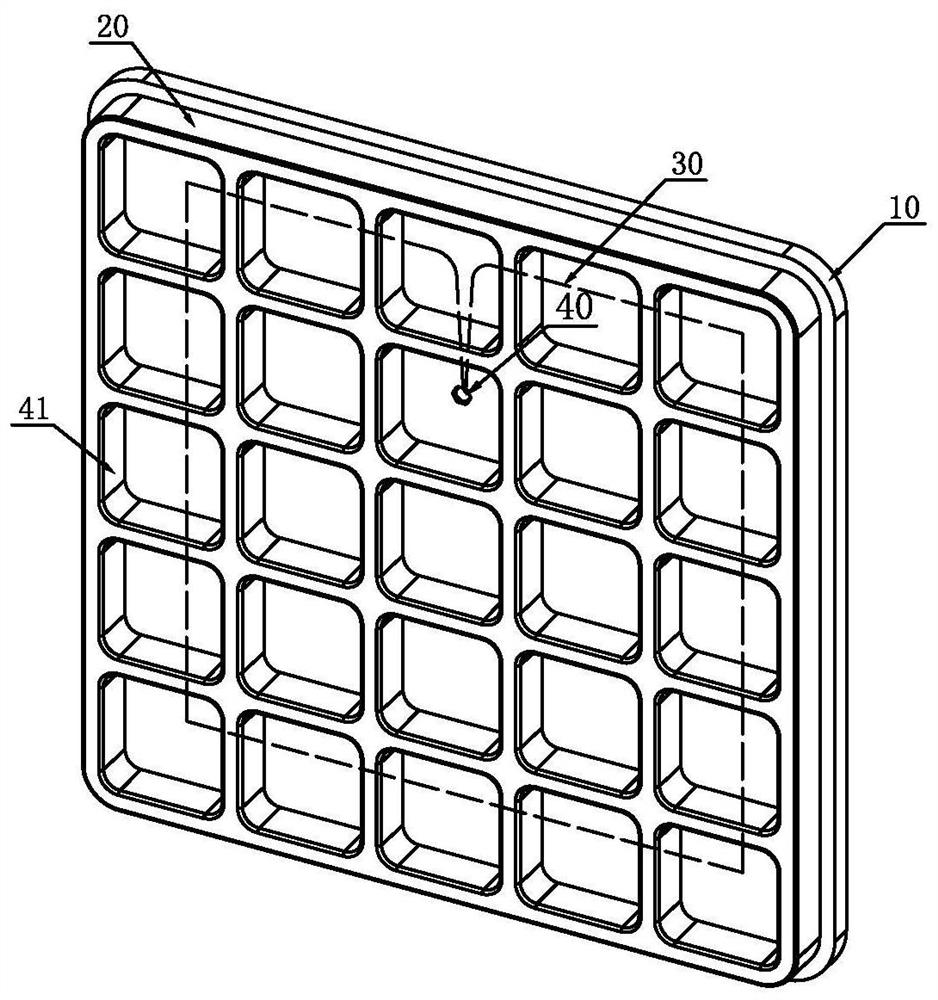

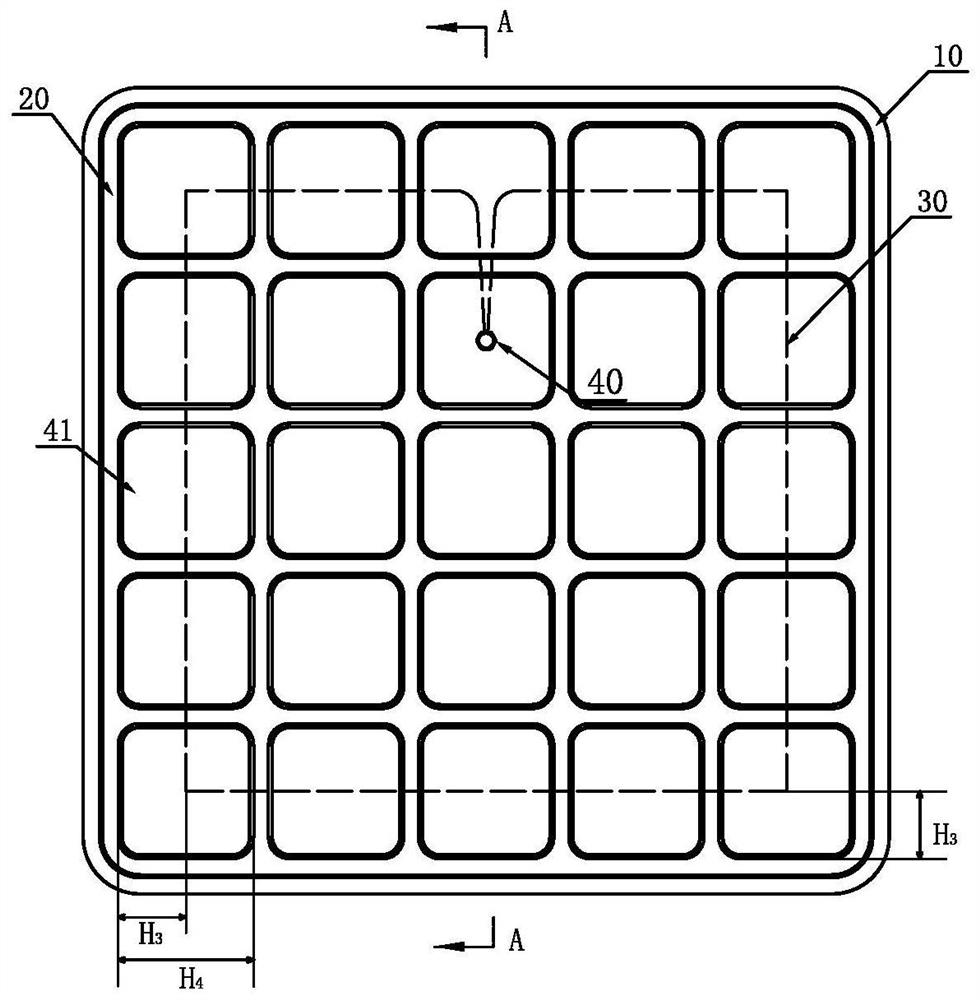

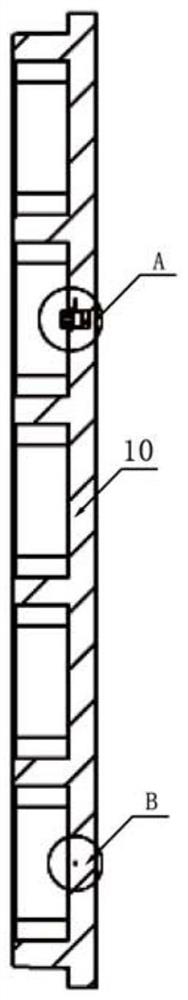

[0043] The first embodiment of the present invention provides a method for pre-embedding sensing lines in the trench cover plate, such as figure 1 and figure 2 As shown, the channel cover plate includes a cover plate upper part 10, a cover plate lower part 20, a sensing line 30 embedded in the upper part of the cover plate, connected with the sensing line 30 and lowered from the cover plate upper part 10. The sensing line joint 40 protruding from the end surface and the reinforcement mesh (not shown in the figure) embedded in the lower part 20 of the cover plate, the reinforcement mesh is composed of a plurality of reinforcement grids; the reinforcement mesh connects the lower part 20 of the cover plate Divided into a plurality of hollow grids 41, the hollow grids are preferably square structures, such as Figure 4 As shown, the sensing line joint 40 is located in the hollow grid, and the distance from the surrounding of the hollow grid is 3cm, which is convenient for constr...

Embodiment 2

[0053] The second embodiment of the present invention provides a method for pre-embedding sensing wires in the trench cover plate. The trench cover plate is based on the first embodiment, and the distance between the sensing line 30 and the top surface of the top 10 of the cover plate is the distance H 1 7 / 10 cover plate upper thickness H 2 , the sensing line 30 is located at the outermost hollow grid length H around the lower part of the cover plate 4 at the 3 / 5 position; the cross-sectional diameter of the sensing line is 1mm, and the method comprises the following steps:

[0054] 1) Take the lower mold of the cover plate with blind holes and a plurality of grooves arranged horizontally and vertically on the top surface; the structural diagram of the lower mold of the cover plate is as follows: Figure 6 As shown, the grid size formed by the groove matches the size of the reinforcement grid;

[0055] 2) Place the steel mesh in the groove of the mold under the cover plate;...

Embodiment 3

[0062] The third embodiment of the present invention provides a method for pre-embedding sensing wires in the trench cover plate. The trench cover plate is based on the first embodiment, and the distance between the sensing line 30 and the top surface of the top 10 of the cover plate is the distance H 1 4 / 5 cover upper thickness H 2 , the sensing line 30 is located at the outermost hollow grid length H around the lower part of the cover plate 4 at the 2 / 5 position; the cross-sectional diameter of the sensing line is 1mm, and the method comprises the following steps:

[0063] 1) Take the lower mold of the cover plate with blind holes and a plurality of grooves arranged horizontally and vertically on the top surface; the structural diagram of the lower mold of the cover plate is as follows: Figure 6 As shown, the grid size formed by the groove matches the size of the reinforcement grid;

[0064] 2) Place the steel mesh in the groove of the mold under the cover plate;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com