Automatic obstacle avoidance stand column

An automatic obstacle avoidance and column technology, applied in electric components, legs of general furniture, connection with control/drive circuits, etc., can solve the problems of low sensitivity and accuracy, personal injury, complex structure, etc., to improve sensitivity and accuracy. rate, reduced cost of change, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

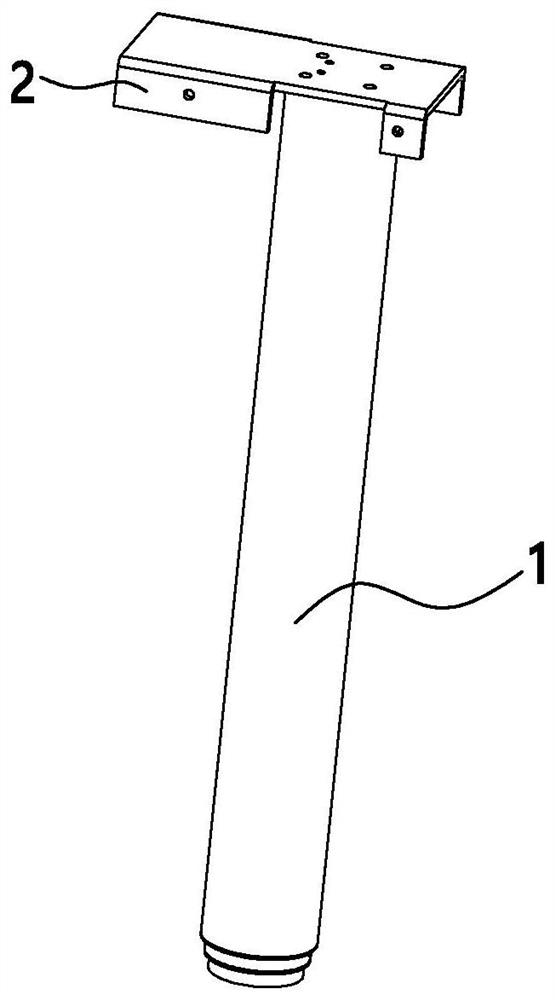

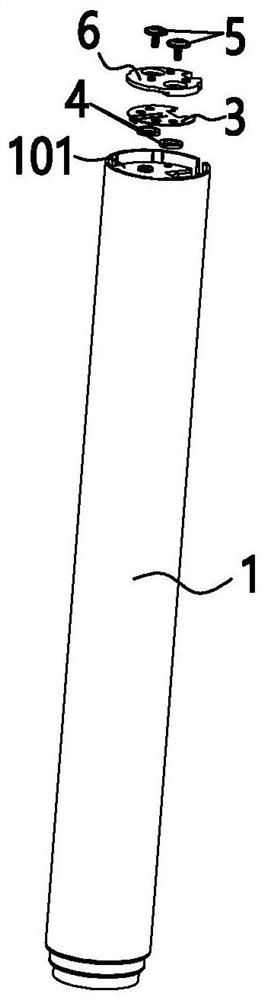

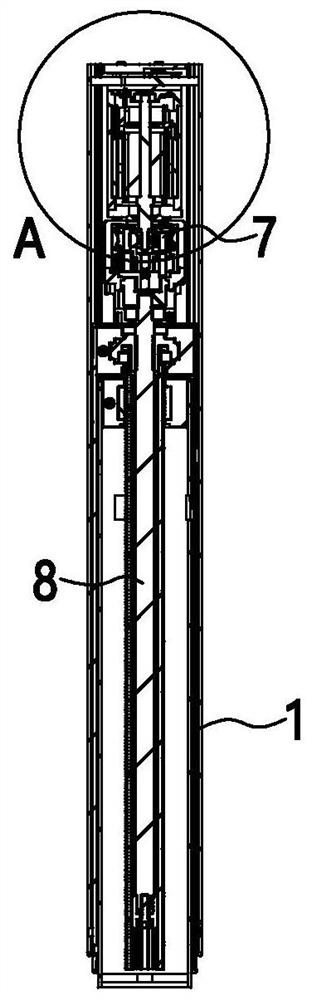

[0031] like Figure 1 ~ Figure 4 As shown, an automatic obstacle avoidance column includes a telescopic sleeve 1, a drive motor, a main control unit for controlling the drive motor, and a transmission assembly 8 that drives the telescopic sleeve 1 to expand and contract under the drive of the drive motor, and the end of the telescopic sleeve 1 A positioning plate 101 is provided. Strain gauges are installed on the outside of the positioning plate 101. The strain gauges are electrically connected to the main control unit. / or fallback instructions.

[0032] In this embodiment, the strain gauges are arranged on the outside of the positioning plate 101. During the actual use of the column, the end of the column will be connected to external hardware such as the installation frame 2 or the feet. 101 is welded on the telescopic sleeve 1, the external firmware and the positioning plate 101 are squeezed against each other, and the strain gauge is installed between the two, which ca...

Embodiment 2

[0040] A lift table includes a table top, and the automatic obstacle avoidance column described in the above embodiment is arranged under the table top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com