Dust purification treatment device for stone engraving

A technology of dust purification and treatment device, applied in the directions of removing smoke and dust, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of large drop, poor cleaning effect, inability to remove dust, etc. Easy to fix stone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

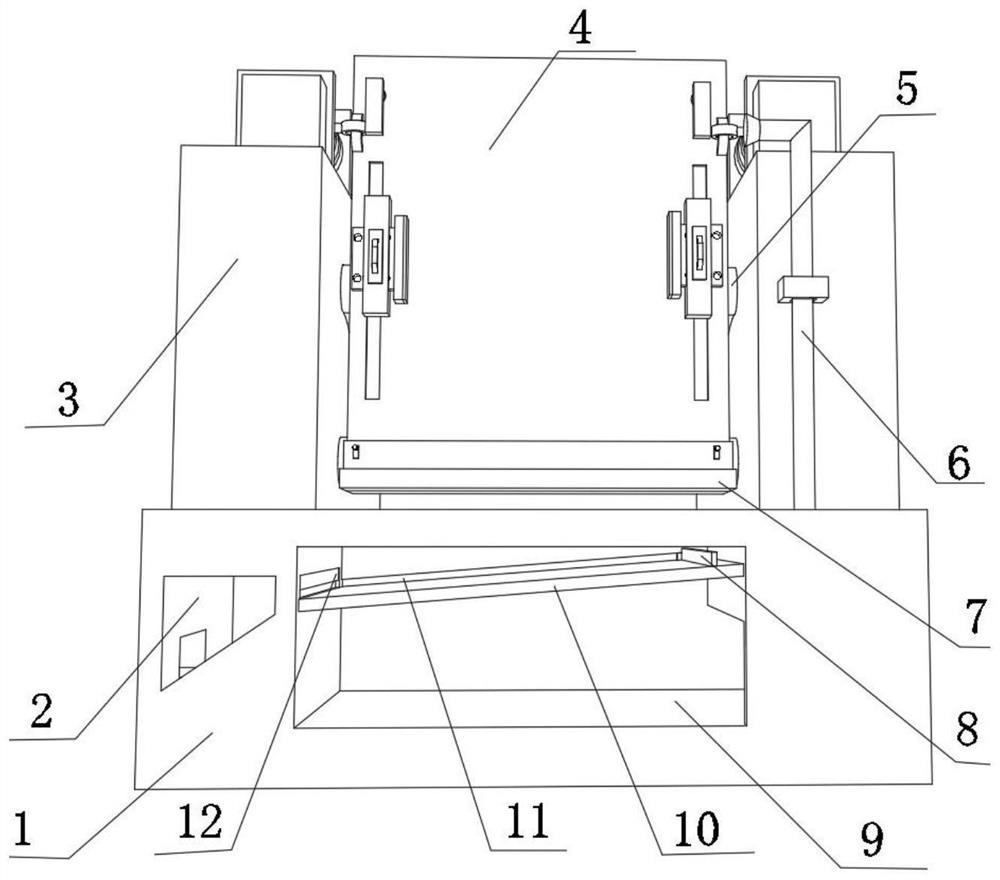

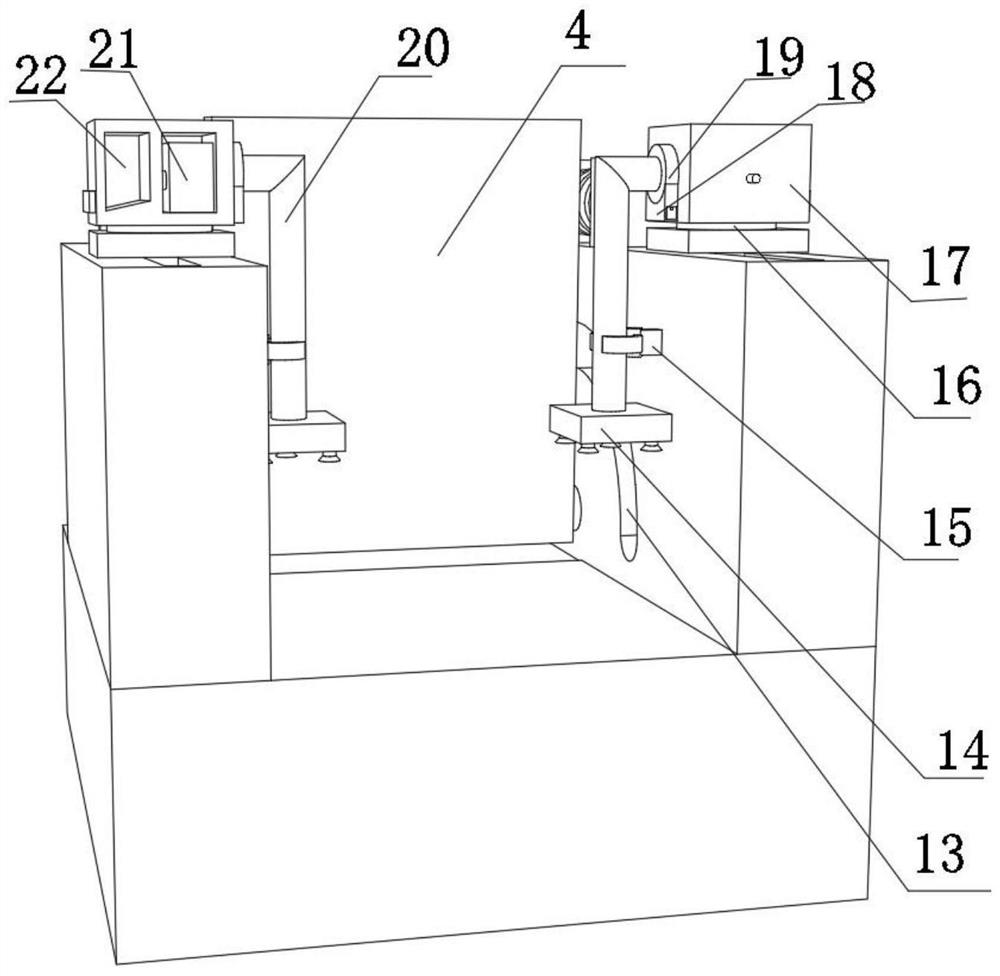

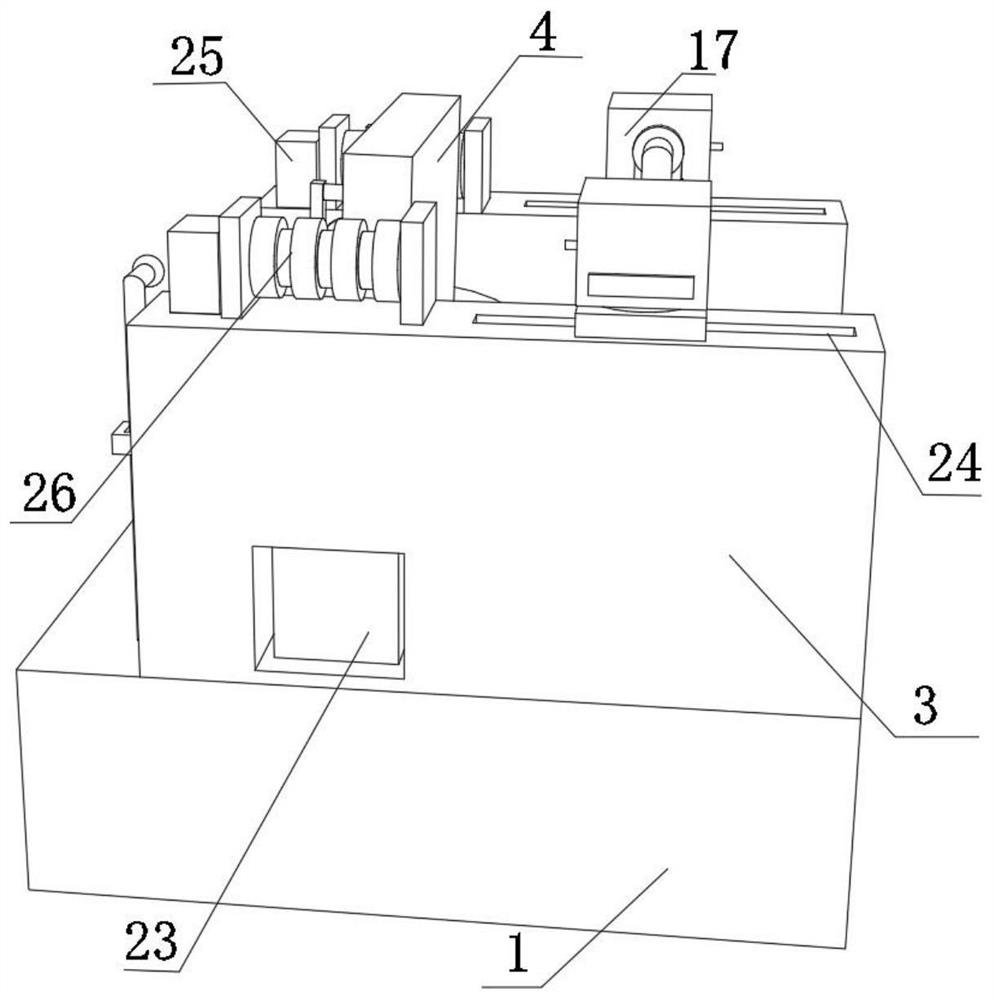

[0032] A dust purification treatment device for stone carving processing, such as Figure 1-4As shown, including the base 1, the top outer wall of the base 1 is fixed with two fixed seats 3 by bolts, the top outer walls of the two fixed seats 3 are provided with moving rails 24, and the inner walls of the two moving rails 24 are all passed through the slider The mounting seat is slidingly connected, and the top outer walls of the two mounting seats are all rotatably connected with a turntable 16. The top outer walls of the two turntables 16 are fixed with a storage box 17 by bolts, and the outer walls of one side of the two storage boxes 17 are fixed with a bolt. Filter assembly 19, the peripheral outer walls of two filter assemblies 19 are all fixed with material receiving box 18 by bolt, one side outer wall of two material receiving boxes 18 is all connected with discharge port by hinge, the inner wall of two filter assemblies 19 all passes through Bolts are used to fix the ...

Embodiment 2

[0038] A dust purification treatment device for stone carving processing, such as figure 1 and Figure 4 As shown, in order to facilitate the washing of carved stones; this embodiment makes the following improvements on the basis of embodiment 1: the top outer wall of the base 1 is fixed with a filter screen 28 by bolts, and the top outer wall of the base 1 is fixed with a sprayer by bolts. Assembly 6, the bottom inner wall of the base 1 is fixed with a water tank 9 by bolts, the bottom inner wall of the water tank 9 is fixed with a water pump by bolts, the output end of the water pump is connected with the input end of the spraying assembly 6 by bolts, and the inner wall of one side of the water tank 9 There is an electric slide rail 11, the inner wall of the electric slide rail 11 is slidably connected with a scraper 8 through a slider, the inner wall of the water tank 9 close to the electric slide rail 11 is fixed with a filter plate 10 by bolts, and the top inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com