Auxiliary assembly device based on installation of small injection mold

A technology of auxiliary assembly device and injection mold, which is used in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of scrapping of the punching needle fixing plate, skewed hammering direction, low practicability, etc., to reduce labor intensity, The effect of high degree of automation and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

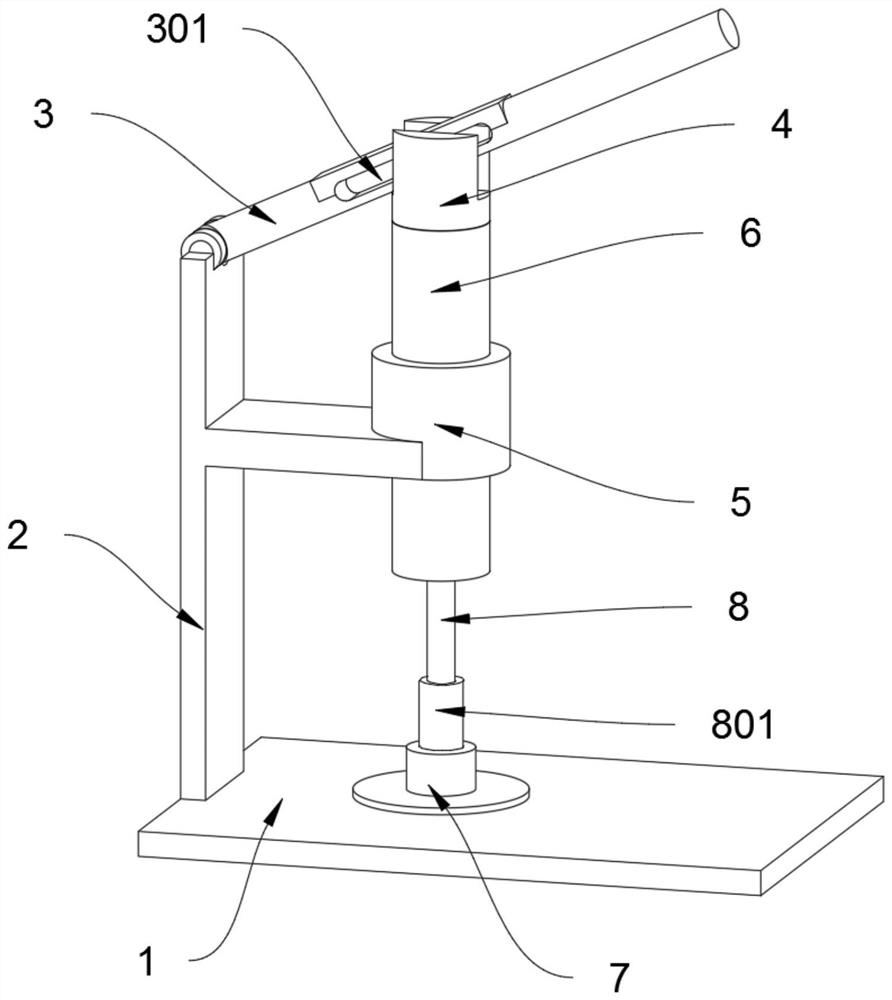

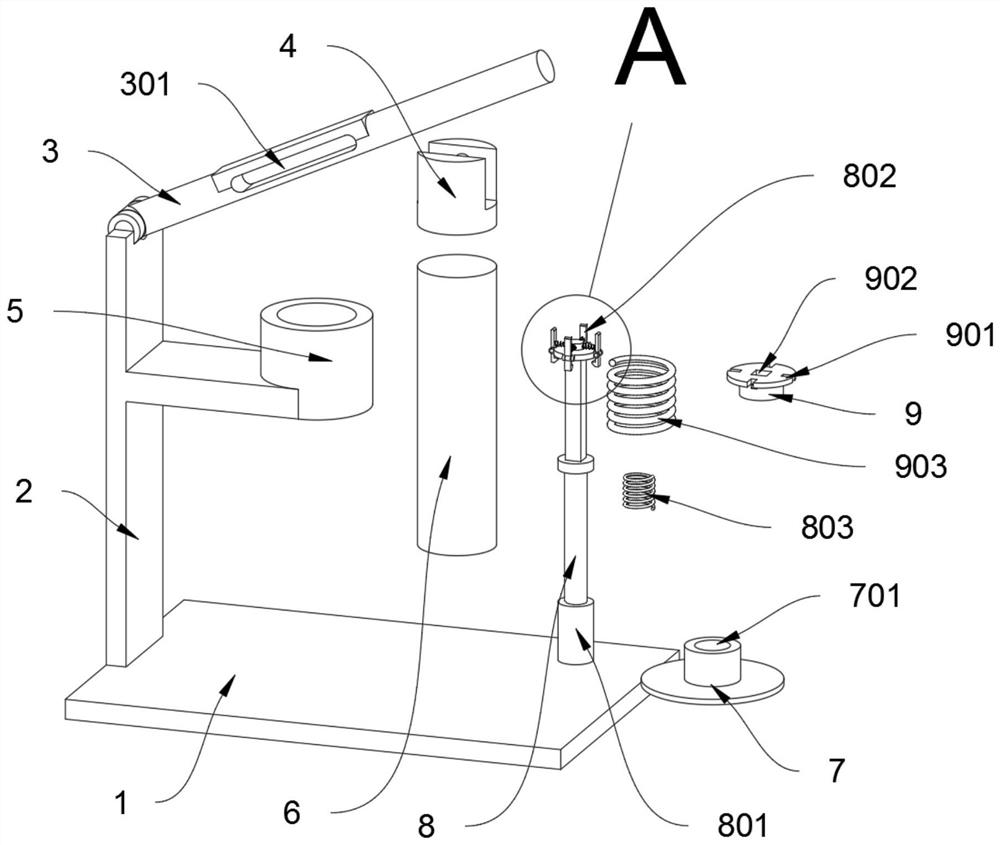

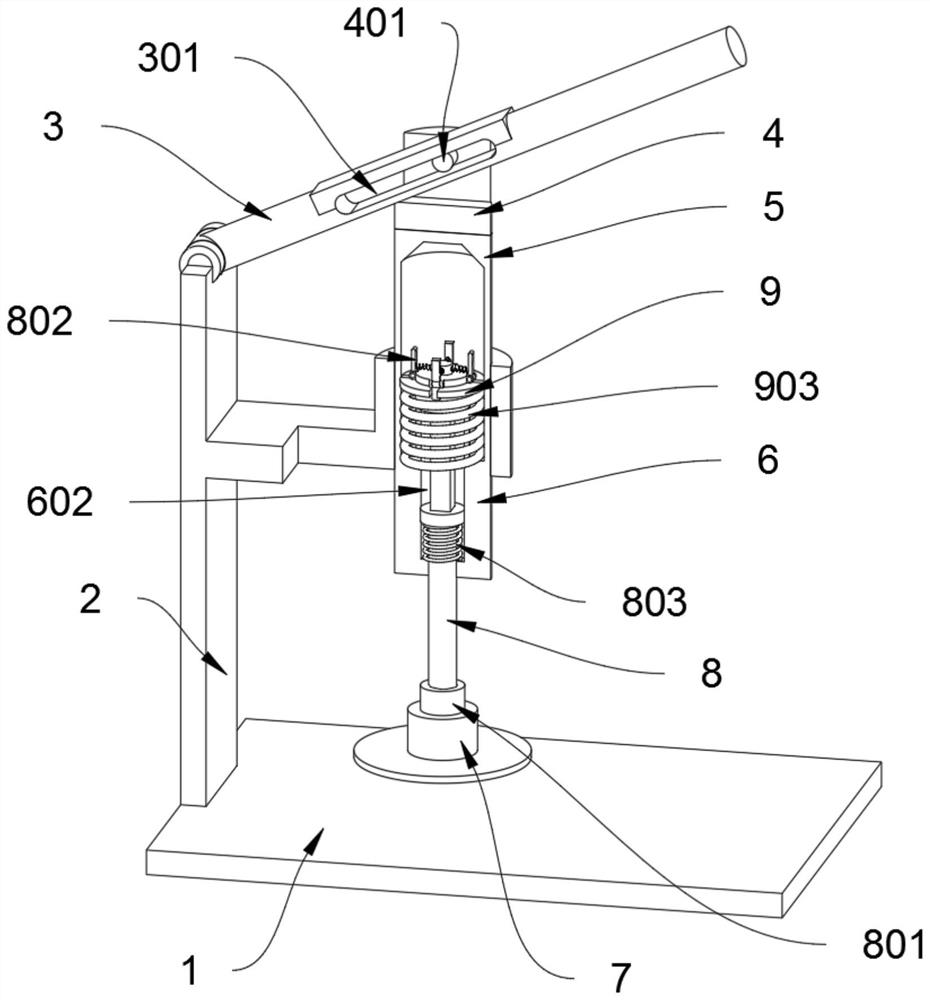

[0036] as attached figure 1 To attach Figure 9 Shown:

[0037]The invention provides an auxiliary assembly device based on the installation of a small injection mold, which includes a working platform 1, a pressure rod 3, a linkage cap 4, a track tube 5, a positioning plate 7 and a kinetic energy block 9; the side of the working platform 1 is fixedly connected with a support Vertical plate 2; one end of pressure rod 3 is connected to the top of supporting vertical plate 2 by rotation; linkage cap 4 is screwed and fixed on the top of hammering shell 6; the middle rod body of pressure rod 3 is provided with linkage groove 301, and the linkage groove 301 is a strip shape, and the inside of the avoidance groove on the top surface of the linkage cap 4 is provided with a linkage rod 401, and the linkage rod 401 is inserted in the inside of the linkage groove 301, as attached figure 2 And attached image 3 As shown, this design makes when the pressure rod 3 is pulled up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com