Dead zone locking device and side guard plate locking system comprising dead zone locking device

A technology for locking devices and side guards, applied in transportation and packaging, railway car body parts, railway car bodies, etc., can solve problems such as inconvenient operation, waste of manpower and time, and low efficiency, and save manpower and time , improve work efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

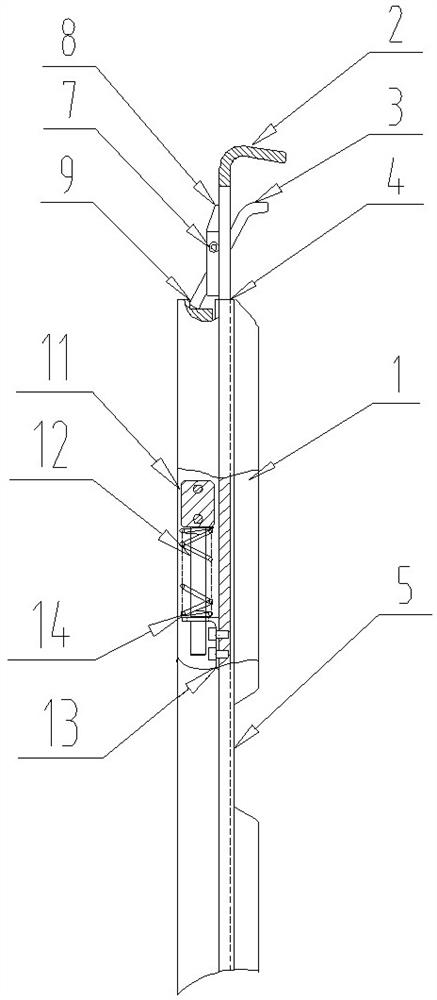

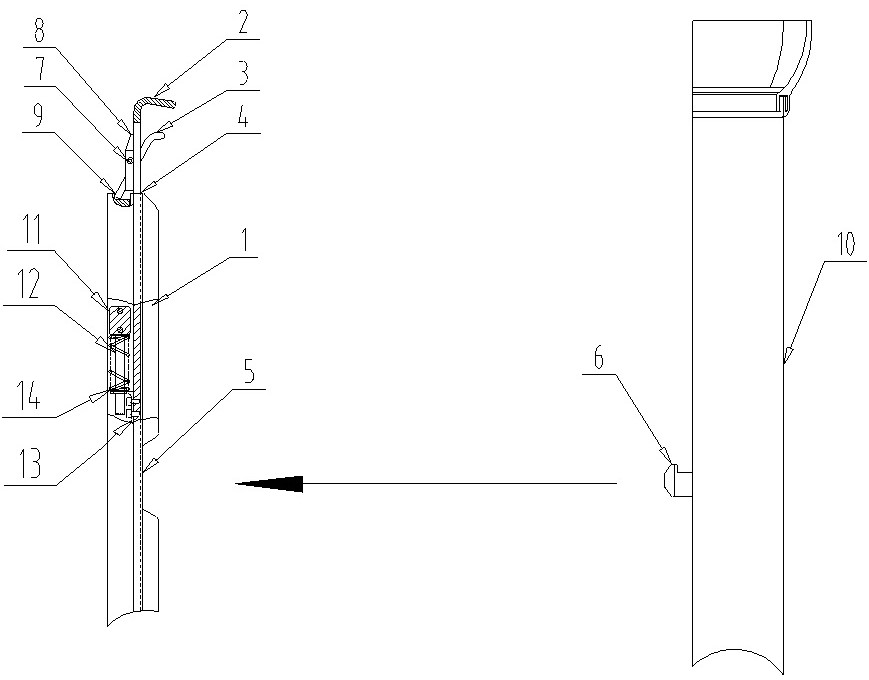

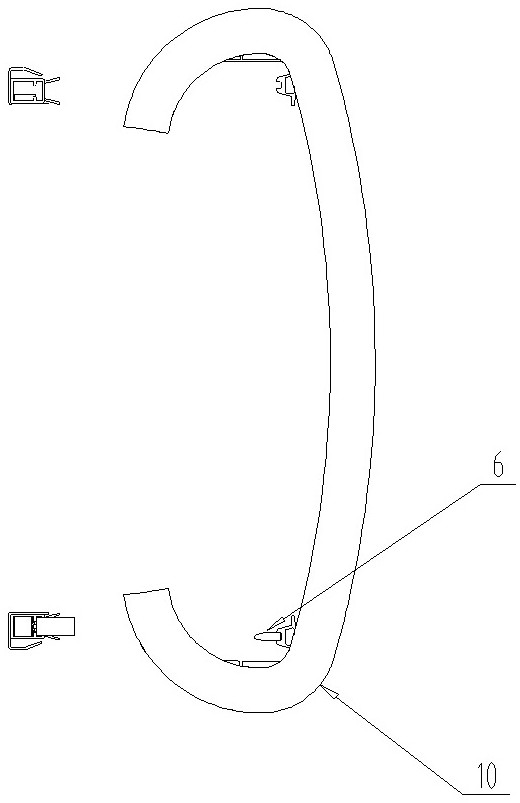

[0024] Combine below Figure 1 to Figure 5 A blind spot locking device and a side guard locking system including the blind spot locking device according to the present invention are described in detail.

[0025] Such as figure 1 As shown, the blind spot locking device of the present invention includes a frame body 1 , a locking plate 2 , a support column 3 , and a positioning shaft 7 .

[0026] The frame body 1 is provided with a chute 4 along the height direction, and the lower part of the lock plate 2 is placed in the chute 4 and can slide along the chute 4 .

[0027] A locking opening 5 is provided on the locking plate 2; the corresponding frame body 1 is also provided with a locking opening there.

[0028] In the middle of the lock plate 2, there is a lock plate through groove capable of accommodating the support column 3, and the support column 3 can rotate in the lock plate through groove.

[0029] The same side of the top of the lock plate 2 and the support column 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com