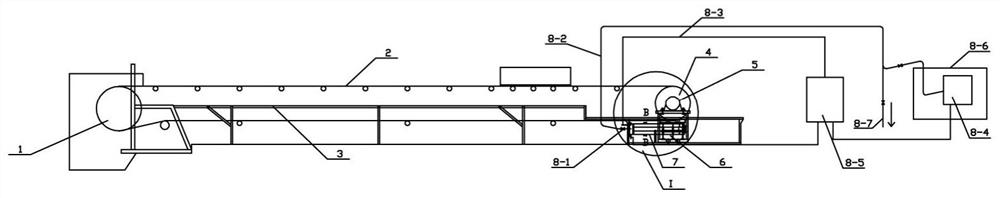

Conveyor belt tensioning force detection and control device

A technology for control devices and conveyor belts, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., to achieve the effects of avoiding lost rotation or slipping, reducing impact, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

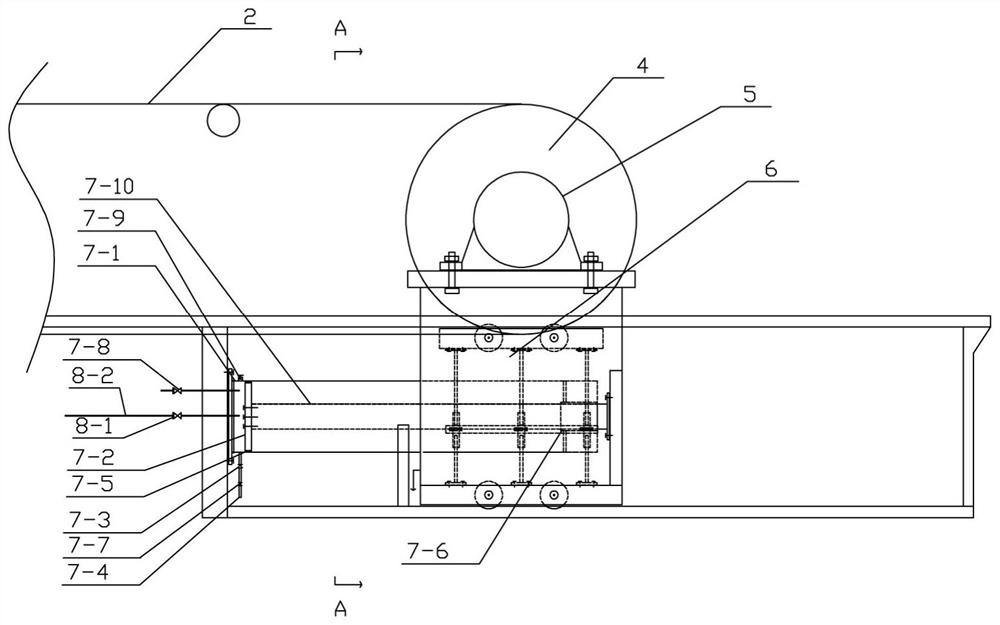

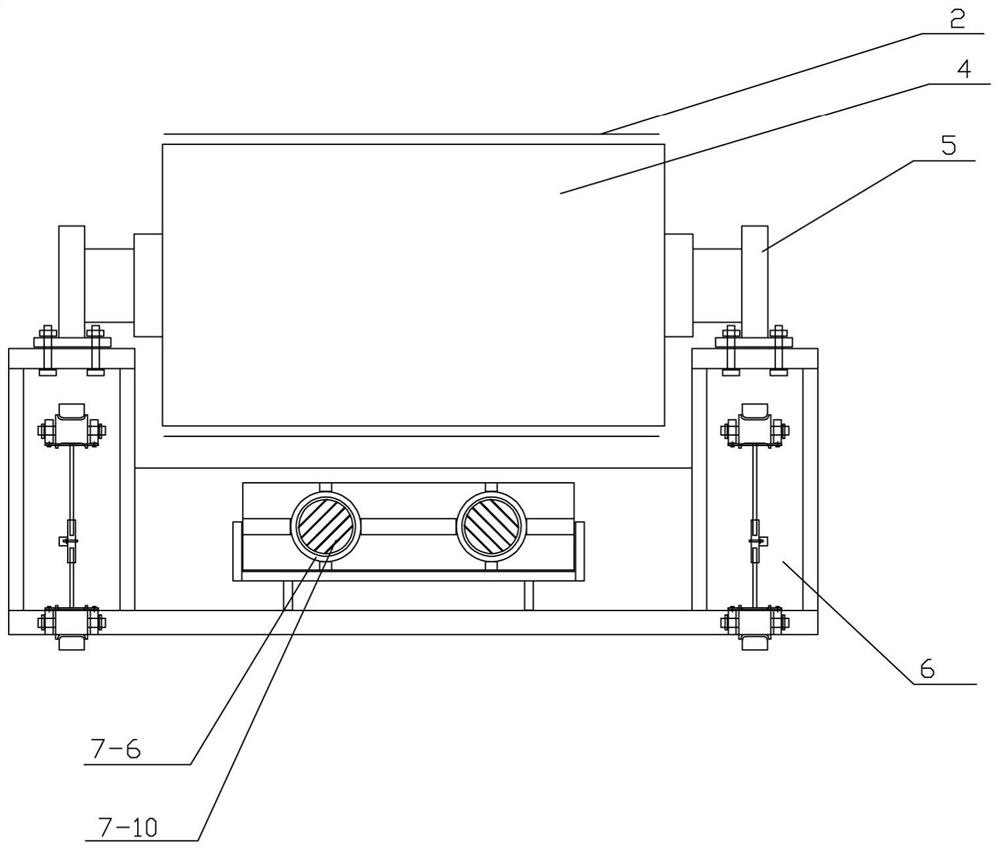

Method used

Image

Examples

Embodiment

[0044] A conveyor belt 2 with a width of 800mm, a belt speed of 1.25m / s, a length of 28m, a diameter of the driving drum 1 of 630mm, the material to be transported is iron concentrate, and the conveying capacity is 400t / h. According to the calculation, the tension of the conveyor belt is 17.28KN , the tension force is 6.31KN; the bearing plate is 100mm high and 250mm wide;

[0045] Based on F=P*S and rated tension F 0 When it is 6.31KN, the rated pressure in the air chamber can be obtained as 0.2524MPa, so the range of pressure transmitter 8-4 is 0.6MPa; 4 Calculate the tension F of the conveyor belt 2 in real time from the online detection data 1 and the rated value F of the specific tension force in the design of the conveyor belt 2 0 It is 6.31KN, the upper limit of the interval is 6.3731KN and the lower limit of the interval is 6.2469KN:

[0046] When F 1 p 6.2469KN, open the intake solenoid valve 7-7, inflate the air chamber, the pressure in the air chamber increases,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com