Novel fabricated cast steel joint of grid structure

A prefabricated, cast steel technology, applied in building structure, construction, etc., to achieve the effect of simple form, lower project cost, and clear force transmission route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical purpose, technical means and beneficial effects of the present invention clearer, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

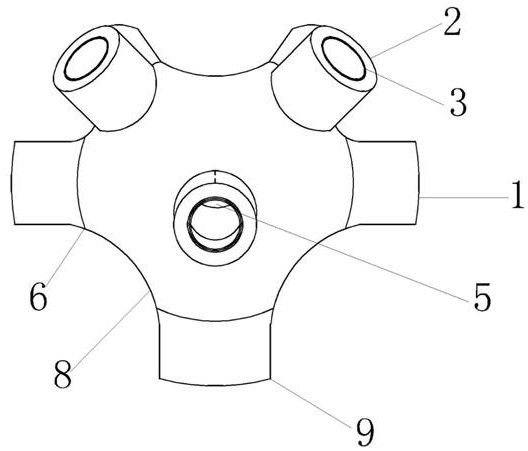

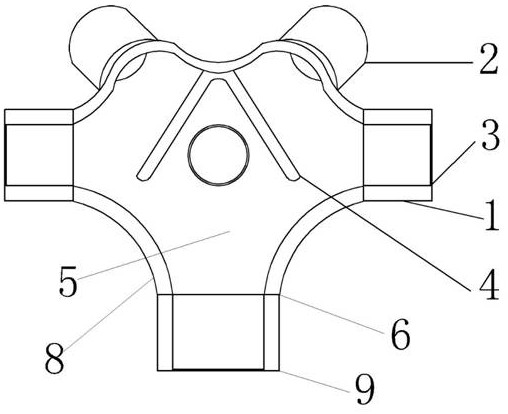

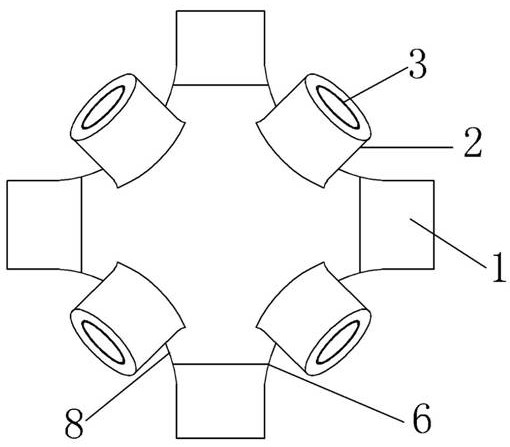

[0038] Such as Figure 1-4 As shown, the middle steel ball has 9 protruding tubes, the upper part obliquely protrudes 4 secondary tubes, the middle part protrudes 4 secondary tubes horizontally, and the lower part has a protruding main tube. The ball and the protruding tube are integrally formed. The tube has an outer radius of 60mm and an inner radius of 40mm, and the overhanging main tube has an outer radius of 80mm and an inner radius of 60mm. The inside of the connection between the overhanging tube and the ball is hollow.

[0039] figure 1 It is the front view of the prefabricated node of the present invention, figure 2 It is an axial sectional view of the fabricated node of the present invention, image 3 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com