Reinforcing Method of Brick Lining in Strong Corrosive Environment

A strong corrosion and lining technology, applied in construction, building maintenance, building construction, etc., can solve the problems of long construction period, corrosion of lining substrate, high maintenance cost, etc., to reduce construction cost and difficulty, shorten construction period and shorten construction period. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

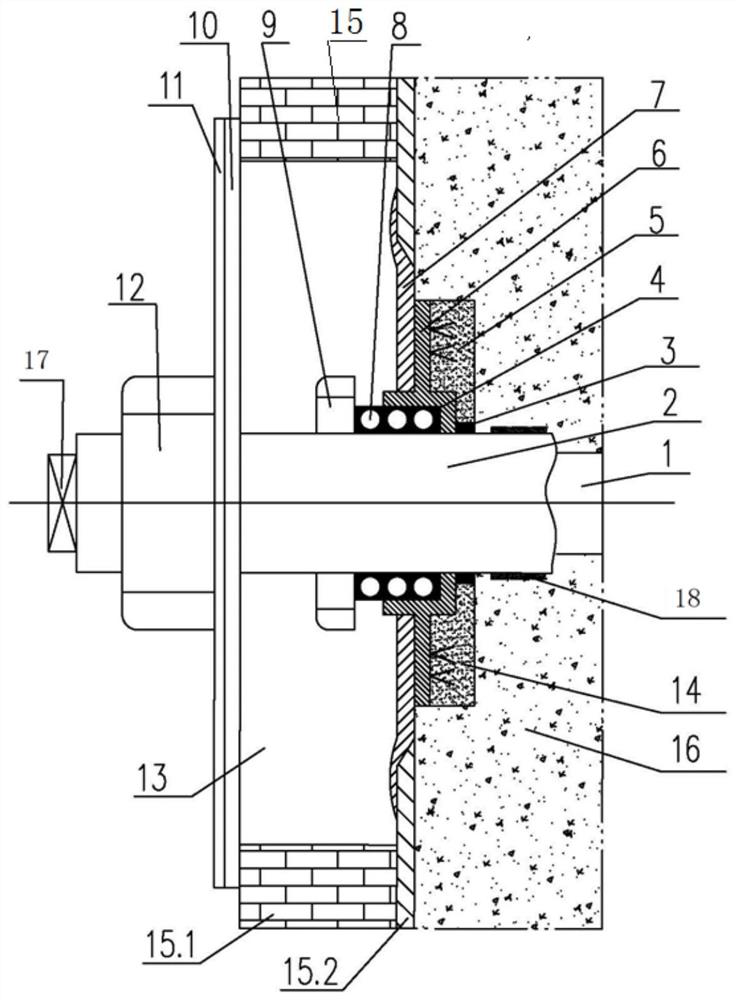

[0021] Below in conjunction with accompanying drawing, the method of the present invention is further explained:

[0022] see figure 1 , the reinforcement method of the present invention comprises the following steps:

[0023] S1) The brick lining 15 at the reinforcement point is taken out of the cavity 13 to expose the surface of the lining matrix 16; the grouting groove 14 is excavated downward on the surface of the lining matrix 16, and the bolt hole 1 is opened downward at the center of the grouting groove 14, and Install the self-tightening part 18; the bolt hole 1 may not penetrate the lining matrix 16, or it may be a through hole penetrating the lining matrix 16. When the bolt hole 1 is a through hole, the remaining space after the bolt 2 is installed can be used as an observation hole through the lining The other side of the substrate 16 observes whether there is any leakage in the hole;

[0024] S2) Put the lower end of the bolt 2 into the self-tightening part 18 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com